A Guide to the ABB Flow Meter

An ABB flow meter is a high-precision industrial sensor designed to measure the rate at which a fluid or gas travels through a pipe. It is the kind of device that delivers critical data for efficiency, cost control and safety in sectors ranging from water management to advanced energy systems.

You can think of it as a smart utility meter but for industrial pipelines, giving you real-time insights into how your processes are actually performing.

Understanding the Critical Role of ABB Flow Meters

Imagine trying to manage a city's water supply without knowing how much is flowing through the main pipes. Or operating a rapid EV charging station without controlling the coolant that stops it from overheating. In scenarios like these, a lack of precise measurement creates immense risk and inefficiency.

An ABB flow meter is the device that provides this essential data, acting as the eyes and ears of a complex fluid system.

At its core, a flow meter answers a simple but vital question: "How much is moving through this pipe right now?" The answer is fundamental to nearly every industrial process. Without it, operators are flying blind, unable to control costs, optimise performance or ensure safety. This is where you really start to see why accurate flow measurement is so important.

The Foundation of Process Control

Precise measurement is the bedrock of control. Take the burgeoning field of EV charging and grid-scale batteries for instance. Managing thermal loads in these systems is completely non-negotiable. An ABB flow meter can measure the exact flow of liquid coolant, allowing a system to:

- Prevent overheating in rapid EV chargers by ensuring adequate heat dissipation.

- Maintain optimal operating temperatures for large grid-scale batteries, which extends their lifespan and keeps them safe.

- Enhance efficiency in distributed energy systems by precisely managing heat transfer fluids from combined on-site renewables.

This level of control is vital for maintaining the stability and resilience of modern energy infrastructure, particularly for EV charging from constrained grid connections. You can explore more on how advanced energy solutions support grid stability in our detailed guide.

Core Technologies Explained Simply

ABB offers a variety of flow meter technologies and each one is suited to different tasks. Two of the most common principles you'll come across are electromagnetic and Coriolis .

An electromagnetic meter is perfect for conductive fluids, like water. It works by measuring the voltage generated as the fluid passes through a magnetic field—a bit like a tiny generator whose power output is directly proportional to the fluid's speed.

Coriolis meters are even more versatile. They measure mass flow directly by sensing the tiny twisting forces created by fluid moving through oscillating tubes. This method is incredibly precise and can measure almost any fluid or gas, making it indispensable for applications needing exact dosing or density measurement.

An ABB flow meter transforms an invisible process—the movement of fluid inside a pipe—into actionable data. This data is the key to unlocking efficiency, ensuring safety and driving optimisation in countless industrial applications.

As a global leader, ABB has a significant presence here in the UK, offering a wide array of these technologies. Product families like ProcessMaster and AquaMaster are used extensively in UK industrial control and water management, delivering reliable data day in, day out.

ABB's integration of cloud-enabled devices and real-time monitoring also supports the kind of predictive maintenance and smart asset management that is crucial for the UK's push towards Industry 4.0 and green energy. This focus on digital innovation really underscores why an ABB flow meter is more than just a sensor; it is a cornerstone of modern industrial intelligence for distributed energy.

Exploring the Main Types of ABB Flow Meters

Choosing the right ABB flow meter is not about finding a single "best" technology. It is about matching the right tool to a specific industrial challenge. Each type works on a different physical principle, making it perfectly suited for measuring certain fluids and gases in particular environments. Getting this match right is the secret to accurate, reliable data.

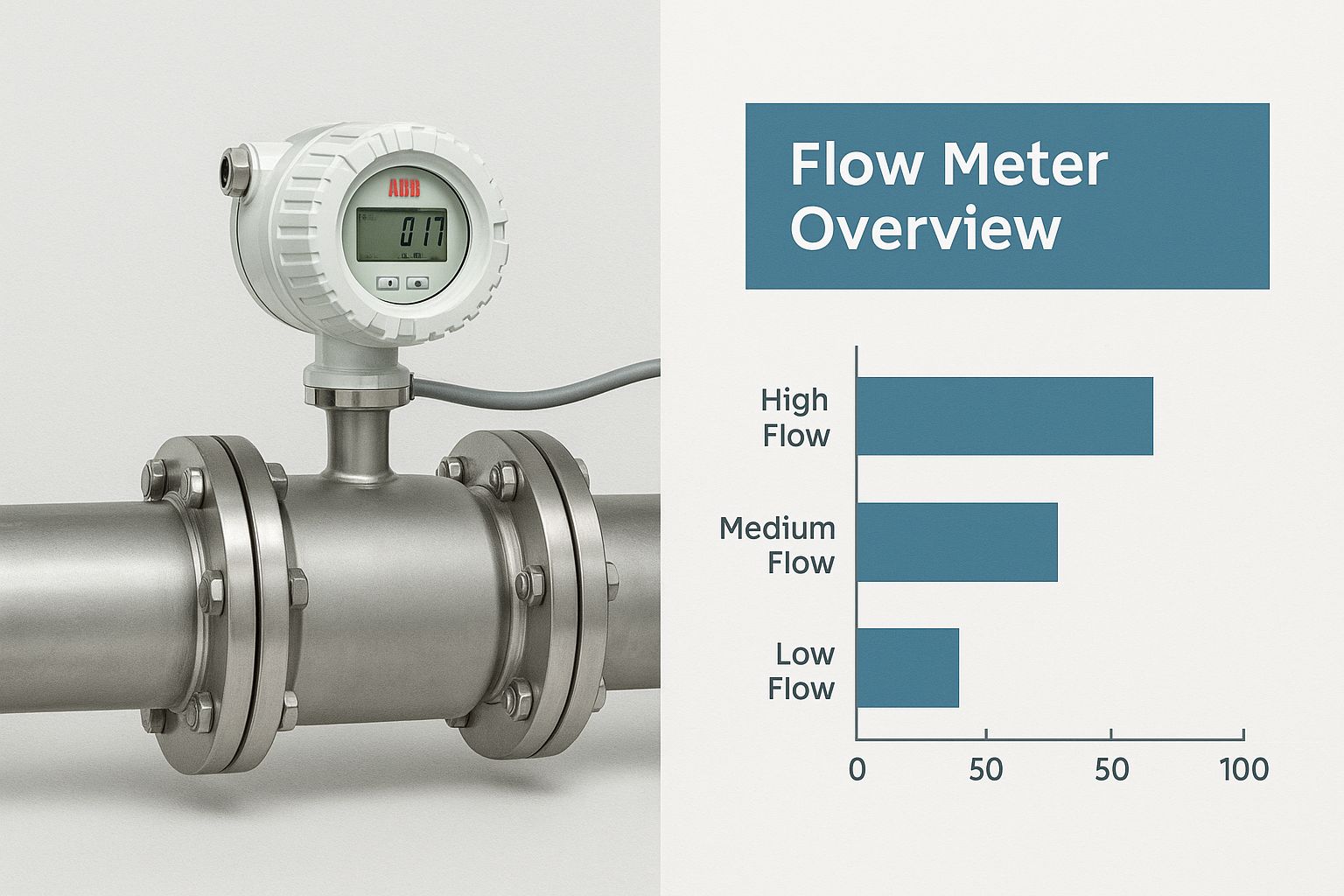

The image below gives you a bird's-eye view of how an ABB flow meter fits into a typical industrial setup.

As you can see, it integrates directly into the pipeline, giving operators the crucial data needed for tight process control and better efficiency. Now, let’s get into the main technologies ABB has to offer.

Electromagnetic Flow Meters

Electromagnetic meters, or 'mag meters' as they’re often called, are the workhorses for measuring conductive fluids. You can think of them as tiny electrical generators. When a conductive liquid like water or wastewater moves through a magnetic field created by the meter, it generates a voltage. That voltage is directly proportional to how fast the fluid is moving, allowing for an incredibly precise flow rate calculation.

Because there are no moving parts and the design is just a straight, unobstructed tube, they are exceptionally reliable and need very little maintenance. This makes them the go-to choice for:

- Utility networks: Keeping tabs on drinking water distribution and sniffing out leaks.

- Wastewater treatment: Accurately measuring the flow of influent and effluent.

- Industrial processes: Managing water-based coolants and various chemicals.

Their dominance in these areas is undeniable. The UK flow meter market stood at an approximate revenue of USD 677.0 million in 2024 , which shows just how much demand there is for accurate measurement. Of that, the magnetic flow meter segment captured a huge 28.2% share , highlighting its critical role in everything from water supply to chemical processing—especially as utilities upgrade their infrastructure to meet tough Ofwat regulations. You can explore further market trends for flow meters and see the full analysis.

Coriolis Mass Flow Meters

When the highest precision is an absolute must, Coriolis meters are the answer. These advanced instruments measure mass flow directly, which is a massive advantage over simply measuring volume. Why? Because mass is not affected by changes in the fluid’s density, temperature or pressure.

Picture swinging a garden hose from side to side. As water rushes through it, the hose twists just a tiny bit. A Coriolis meter uses oscillating tubes that create a similar, measurable twisting force caused by the momentum of the fluid. This tiny twist, known as a phase shift, is directly proportional to the mass flow rate.

By measuring both mass flow and density in a single device, an ABB Coriolis meter gives you deeper insight into process quality and consistency. It essentially does the work of multiple instruments at once.

This unique ability makes them essential for applications where the composition of the fluid is just as vital as its flow rate. Common uses include:

- Chemical dosing: Making sure the exact amount of a substance is added to a mixture.

- Hydrogen applications: Accurately measuring the mass of gas for custody transfer as energy networks decarbonise.

- Food and beverage: Controlling the blending of ingredients where density indicates quality, like mixing fruit into yoghurt.

To help you decide which technology is the best fit for your needs, here is a quick comparison of the main types of ABB flow meters.

ABB Flow Meter Technology Comparison

This table breaks down the operating principles and ideal use cases for each major flow meter technology, making it easier to see which one aligns with your specific industrial application.

| Technology Type | Operating Principle | Ideal Applications | Key Advantage |

|---|---|---|---|

| Electromagnetic | Measures voltage generated by a conductive fluid moving through a magnetic field (Faraday's Law). | Water & wastewater, chemicals, pulp & paper, mining. | No moving parts, minimal pressure drop, excellent for conductive and corrosive liquids. |

| Coriolis Mass | Measures the twisting force (Coriolis effect) of fluid moving through oscillating tubes to determine mass flow directly. | Chemical dosing, custody transfer, food & beverage, hydrogen fuel. | Measures mass flow and density directly; unaffected by fluid properties like temperature or pressure. |

| Vortex | Measures the frequency of vortices created by a shedder bar in the flow path. | Steam, gases and low-viscosity liquids, particularly in utilities and energy. | Highly reliable, versatile across liquid, gas and steam; handles high temperatures and pressures. |

| Thermal Mass | Measures the cooling effect of gas flow over a heated sensor to determine mass flow. | Low-flow gas measurement, leak detection, aeration control, flare gas monitoring. | High sensitivity at very low flow rates; directly measures gas mass flow. |

Each of these technologies solves a different piece of the measurement puzzle, ensuring you can get the right data, no matter how demanding the environment.

Vortex and Thermal Mass Flow Meters

Beyond the big two, ABB also offers specialised meters for gas and steam applications where electromagnetic and Coriolis technologies might not be the best fit.

Vortex flow meters are famously robust and versatile, making them a fantastic choice for measuring the flow of steam, gases and low-viscosity liquids. They work by placing a small obstruction, called a shedder bar, in the flow path. This creates alternating vortices—think of the ripples you see behind a rock in a stream. A sensor counts these vortices and their frequency is directly related to the flow velocity.

On the other hand, thermal mass flow meters are designed for the delicate, precise measurement of gas flows, especially at low rates. They use a heated sensor and a temperature sensor to measure the cooling effect of the gas as it passes by. The amount of heat carried away is proportional to the mass flow rate of the gas. This makes them perfect for sensitive jobs like monitoring flare gas or managing aeration processes in treatment plants.

How to Select the Right ABB Flow Meter

Picking the right ABB flow meter is not just a technical box-ticking exercise. It is a crucial decision that directly affects your data accuracy, operational efficiency and the reliability of your entire system. The wrong meter can lead to dodgy process control and costly mistakes, especially in tough applications like grid-scale battery thermal management or rapid EV charging. Getting it right means taking a methodical look at your specific operational needs.

To make things simpler, we can break the process down into three core areas. By carefully thinking through your fluid properties, flow conditions and accuracy needs, you can confidently zero in on the ideal ABB flow meter for the job.

Analysing Fluid Properties

First things first, you need to understand the fluid itself. Different flow meter technologies are built to handle specific types of liquids and gases, so matching the meter to the medium is absolutely essential for both accuracy and a long service life.

Think about the fluid's key characteristics:

- Conductivity: Is the fluid electrically conductive? For liquids like the water or water-glycol coolants found in EV charging stations and battery energy storage systems (BESS), an electromagnetic meter is often a perfect match. On the flip side, they are no use for non-conductive hydrocarbons or deionised water.

- Viscosity and Density: How thick is the fluid and does its density change? For viscous fluids or jobs where density measurement is vital—like making sure coolant additives are at the right concentration—a Coriolis meter is in a class of its own. It measures mass directly, so its readings are not thrown off by changes in fluid properties.

- Composition: Are you dealing with a clean liquid, a gas or a slurry with solids in it? Abrasive slurries can chew up certain types of meters. Coriolis meters, with no moving parts inside and a robust tube design, can be built to handle these challenging conditions far better than other technologies.

Evaluating Flow and Installation Conditions

Once you've got a handle on the fluid, it is time to look at the environment where the meter will live. The physical conditions of your pipeline and process will have a big say in which ABB flow meter is the right fit.

Here are the key operational factors to consider:

- Flow Rate Range: Will the flow be steady or will it jump around all over the place? The turndown ratio is a crucial spec here. It tells you the range over which a meter can measure accurately. A meter with a high turndown ratio, like the ABB CoriolisMaster, delivers reliable data at both very low and very high flow rates. This makes it ideal for systems with fluctuating demand, like a mobile EV charging unit that is not always running flat out.

- Temperature and Pressure: Extreme operating temperatures or pressures, which are common in distributed energy systems, will quickly rule out certain models. Always double-check the meter’s specifications to make sure it can safely handle your application's conditions.

- Installation Space: How much straight pipe do you have to play with? Many meters, especially electromagnetic ones, need a certain length of straight, clear pipe before and after them. This ensures the flow profile is stable enough for an accurate reading. The compact design of some ABB meters, like the CoriolisMaster, can be a massive advantage in tight spots where straight pipe runs are limited.

The right selection process is all about balancing the nature of the fluid with the demands of the system. For instance, monitoring coolant in an EV charging hub with a constrained grid connection needs a meter that is not only accurate but also compact and able to handle variable flow as different chargers switch on and off.

Determining Accuracy and Performance Needs

Finally, you need to decide just how precise your measurements need to be. The level of accuracy required often comes down to the application's purpose. Is it for general process monitoring or is it for critical billing and custody transfer measurements?

For example, tracking coolant flow in a grid-scale battery system demands high reliability to prevent thermal runaway but it might not need the pinpoint 0.1% accuracy of a custody transfer meter. On the other hand, measuring hydrogen for billing would demand the highest precision you can get. An ABB Coriolis meter is often the go-to choice for these critical applications because it provides direct mass flow measurement. This eliminates inaccuracies caused by pressure or temperature swings, ensuring both parties get a fair deal.

By carefully considering these three areas, you'll have a clear framework for choosing the perfect ABB flow meter.

ABB Flow Meters in Modern Energy Systems

The shift towards a cleaner energy future depends on complex, high-performance systems. From rapid EV charging hubs to huge grid-scale batteries, managing energy and heat with precision is not just an option anymore—it is essential. Tucked away at the heart of these modern systems, an ABB flow meter often plays a silent but critical role, ensuring everything runs safely, efficiently and reliably.

These devices are the unsung heroes providing the data needed to handle the thermal loads that push the performance limits of today's energy infrastructure. Without accurate flow measurement, the very systems we're counting on for decarbonisation would be inefficient, unreliable and frankly, unsafe.

Enabling Rapid and Mobile EV Charging

Rapid EV charging stations generate a tremendous amount of heat. To stop components from getting damaged and to deliver the fastest possible charge times, most high-power chargers use sophisticated liquid cooling systems. An ABB flow meter is the key to managing this thermal environment properly.

Fitted into the coolant loop, the meter measures the exact flow rate of the cooling fluid, which is usually a water-glycol mix. This real-time data lets the station's control system tweak the pump speed on the fly, making sure the perfect amount of coolant is always circulating. It is a simple but brilliant way to prevent overheating without wasting energy on over-pumping.

This same principle is just as crucial for mobile EV charging units. These systems have to pack a serious punch in a small package, making thermal management even more of a tightrope walk. A compact, accurate ABB flow meter provides the control needed to keep these mobile powerhouses running safely and efficiently, wherever they are needed.

Protecting Grid-Scale Battery Storage

Grid-scale Battery Energy Storage Systems (BESS) are fundamental to building a stable, renewable-powered grid. They soak up energy when it is plentiful and release it when demand spikes. But the performance and lifespan of these massive battery arrays are directly tied to their operating temperature.

Here again, an ABB flow meter is crucial for the thermal management systems in BESS installations. By monitoring the flow of liquid coolant through the battery racks, operators can:

- Maintain Optimal Temperatures: Keep the batteries operating in their ideal temperature range to maximise lifespan and prevent degradation.

- Prevent Thermal Runaway: A catastrophic failure in batteries that can be triggered by overheating. Precise coolant flow control is a critical safety barrier.

- Improve Round-Trip Efficiency: By minimising the energy spent on cooling, more of the stored energy can be delivered back to the grid.

In these massive projects, the reliability of an ABB flow meter underpins the financial viability and safety of the entire multi-million-pound asset.

Optimising Distributed Energy and Renewables

The modern energy landscape is becoming more and more decentralised. Businesses and communities are generating their own power with on-site renewables like solar panels, often combining them with battery storage to create resilient microgrids. An ABB flow meter has an important part to play in optimising these integrated systems.

For instance, in systems that capture and reuse waste heat, these meters are used to measure the flow of heat transfer fluids. This allows for precise control over thermal energy, ensuring it gets sent where it is needed most. This is especially important for sites with combined on-site renewables, EV charging and batteries , where every single kilowatt-hour has to be managed effectively.

In an integrated energy system, every component must work in harmony. An ABB flow meter provides the granular data needed to fine-tune thermal processes, turning potential energy waste into valuable operational efficiency.

This level of control is what makes on-site generation economically viable and helps slash a facility's overall carbon footprint. It ensures the whole system—from generation to storage to consumption—operates as one cohesive, efficient unit.

Supporting Constrained Grid Connections

Many great locations for new EV charging hubs or renewable projects are held back by constrained grid connections . This means the local grid infrastructure simply cannot handle the full power demand of the new assets. This is where a smart combination of battery storage and intelligent energy management becomes absolutely critical.

Accurate flow measurement is a key piece of this puzzle. By ensuring the thermal management systems for both the EV chargers and the batteries are running at peak efficiency, an ABB flow meter helps to cut down on parasitic energy losses. When every kilowatt-hour counts, eliminating waste in auxiliary systems like cooling is vital.

This meticulous approach to efficiency allows developers to get the most out of their assets without overloading the local grid. Efficient thermal management, made possible by precise flow data, is a cornerstone of effective grid energy management strategies for these challenging locations.

Getting Installation and Maintenance Right

Picking the right ABB flow meter is only half the battle. If you want it to deliver accurate, reliable data for years to come, you have to get the installation and maintenance right. Nailing these fundamentals helps you sidestep the common issues that mess with data integrity and cause expensive downtime.

A solid setup ensures the meter works exactly as it should from day one. It is like laying the foundation for a house – without a good base, even the best materials will not hold up. That initial effort pays off for the entire life of the meter.

Non-Negotiable Installation Rules

The single biggest factor for accurate measurement is a stable, predictable flow profile. If the fluid is turbulent or swirling, it can easily fool the meter into giving you bad readings. So, if you are serious about data quality, sticking to the installation guidelines is non-negotiable.

One of the most important rules is to have enough straight pipe before and after the meter. This simple step gives the flow a chance to settle down before it hits the sensor. For an ABB electromagnetic meter, for instance, you'll typically need a straight run of pipe that is five times the pipe's diameter upstream and two times downstream.

Proper electrical grounding is also critical for electromagnetic meters. If you skip this, electrical noise from nearby equipment like pumps or motors can interfere with the meter's sensitive electronics and throw off your readings.

Proactive Maintenance Strategies

Once your ABB flow meter is installed correctly, the job shifts to keeping it performing at its best. It is always better to be proactive than reactive. Do not wait for a problem to show up; preventative maintenance keeps your meter in peak condition.

A simple visual inspection routine can make a huge difference. Keep an eye out for:

- Physical Damage: Any signs of corrosion, leaks or damage to the meter body or cables.

- Secure Connections: Make sure all electrical connections are tight and shielded from moisture.

- Clear Displays: Check that the local display is working and not flagging any error codes.

This basic checklist helps you catch potential issues long before they turn into major headaches.

Advanced Verification with VeriMaster

For an even deeper level of confidence, ABB provides some powerful diagnostic tools. The VeriMaster software is a perfect example. It lets you run an in-situ verification and calibration check without ever having to pull the meter from the pipeline. This means you do not have to shut down your process, saving a huge amount of time and money.

Think of VeriMaster as a health check for your flow meter. It runs a series of diagnostic tests, compares the results to the meter's original factory calibration data and gives you a detailed report on its performance, confirming its accuracy to within ±1% .

Bringing in a full condition monitoring and predictive maintenance plan can seriously extend the life and reliability of your ABB flow meters. It is a move away from fixing things when they break to proactively managing your assets. If you are looking to explore this advanced approach, this Condition Monitoring & Predictive Maintenance Guide has some great insights.

This kind of smart maintenance fits perfectly into a wider strategy for effective business energy management , where accurate data and dependable equipment are absolutely essential for optimising how you use energy.

In the UK, the push for greater industrial efficiency and better water management is making reliable measurement more important than ever. In 2023, the global market saw sales of nearly 3.79 million flow meter units and the UK was a key player. The drive to cut down on non-revenue water losses—estimated to be between 19% and 25% —has spurred the adoption of smart electromagnetic meters that provide the solid data needed for leak detection and accurate billing.

By pairing correct installation with a smart maintenance plan, you can ensure your ABB flow meter remains a trustworthy source of data for your entire operation.

Frequently Asked Questions

When you are getting into the nuts and bolts of flow measurement, especially for modern energy systems, a lot of questions come up. We get it. Here are some of the most common queries we see about ABB flow meters, covering everything from UK water applications to their role in the booming EV charging sector.

What Is the Best ABB Flow Meter for UK Water Applications?

For water and wastewater jobs here in the UK, the ABB AquaMaster and ProcessMaster electromagnetic flow meters are hands-down the most popular choice. They’re built for conductive liquids like water, giving you high accuracy with minimal maintenance. Because they have no moving parts and a clear bore, blockages just are not an issue.

These meters are also designed to meet the tough standards set by UK water utilities, including regulations for billing and leak detection. The AquaMaster series, in particular, is a common sight for district metering and network management, largely thanks to its battery-powered options and remote communication features.

How Do ABB Flow Meters Improve Rapid EV Charging?

Rapid EV charging stations generate a serious amount of heat. To manage this and protect the equipment (and the car’s battery), high-power chargers rely on liquid cooling systems. An ABB flow meter is a key part of that system.

You’ll often find a compact Coriolis or vortex meter installed right in the cooling loop. It precisely measures the flow rate of the coolant, which lets the station’s control system make sure the perfect amount of fluid is circulating. This level of thermal management allows the station to run at full power safely, delivering those super-fast charging speeds while also extending the life of all the critical components.

Should I Install an ABB Flow Meter Myself?

While a competent mechanical fitter could probably handle the physical side of the installation, commissioning and verification are a different story. This is especially true for certified or fiscal applications, where you need specialist knowledge to get it right.

Proper installation is absolutely critical for accuracy. For example, electromagnetic meters need specific lengths of straight pipe upstream and downstream, not to mention correct electrical grounding.

We always recommend consulting the installation manual for your specific model and bringing in a certified technician or an ABB service engineer. This ensures the meter is installed and commissioned correctly, guaranteeing its performance, accuracy and the validity of your warranty.

Getting a professional involved from the start prevents common mistakes that could throw off your data before you even begin.

What Does Turndown Ratio Mean for a Flow Meter?

The turndown ratio is a really important spec that tells you the range over which a flow meter can accurately measure flow. Think of it as the ratio of the maximum flow rate to the minimum flow rate the meter can handle while still staying within its stated accuracy.

For example, a meter with a 100:1 turndown ratio can accurately measure flow from just 1% all the way up to 100% of its maximum capacity. This is vital in applications where flow rates swing wildly—like in batching processes or systems that idle low but also run at high capacity. We see this a lot in mobile EV charging or combined renewable energy systems. A higher turndown ratio simply means the meter is more versatile and gives you reliable readings across a much wider operational range.

At ZPN Energy , we integrate cutting-edge components to build the future of energy management and EV charging infrastructure. Our systems are designed for maximum efficiency and reliability, from grid-scale battery storage to rapid charging hubs.

Discover how our solutions can power your transition to a sustainable future by visiting us at https://www.zpnenergy.com.