A Guide to Voltage for Mexico and EV Charging

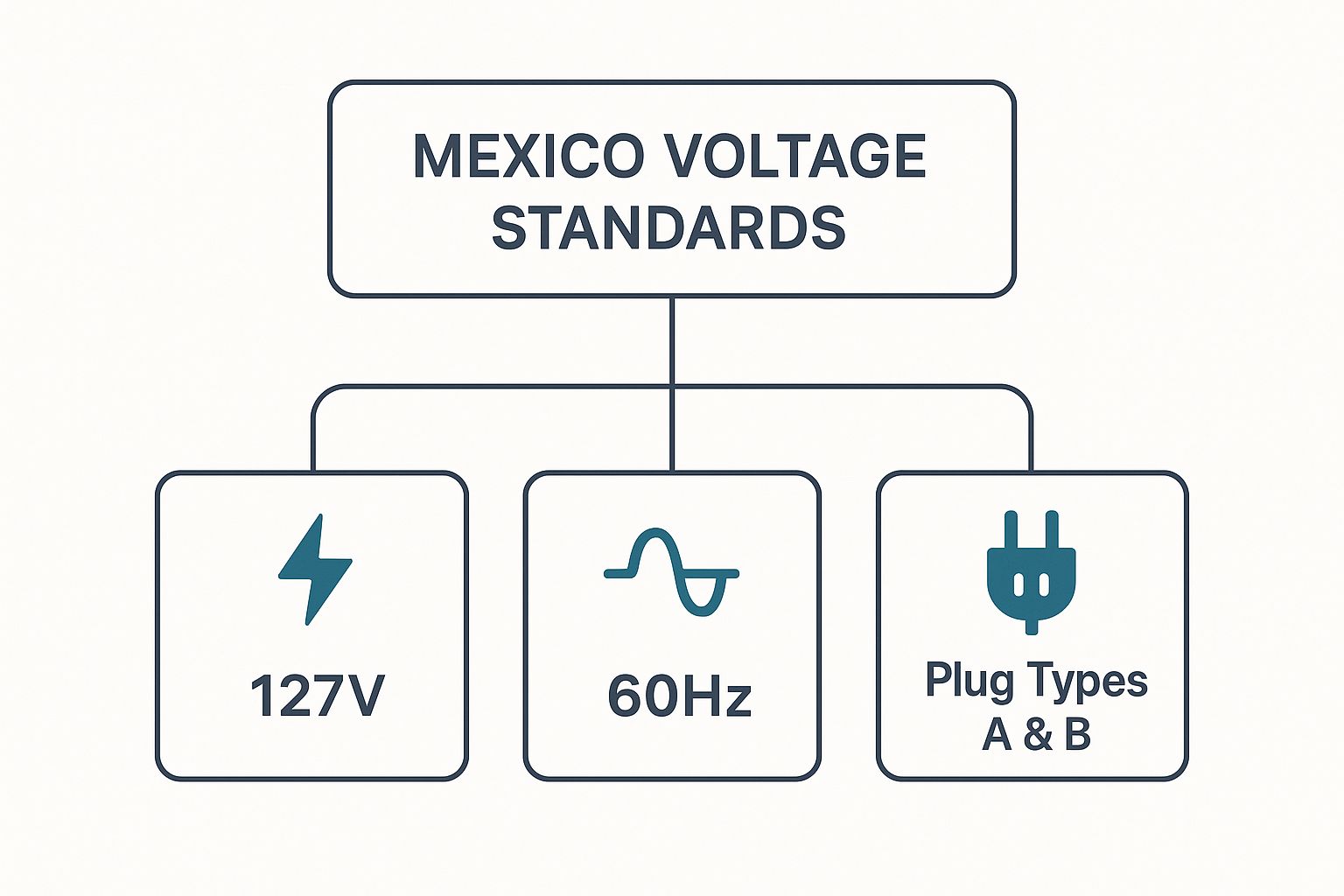

Let's get one thing straight about the power grid in Mexico. On the surface it looks a lot like what you would find in the US or Canada. The standard voltage from a wall socket is 127V running at a frequency of 60Hz .

For the average tourist that is all you really need to know. But for anyone looking to deploy serious high-power equipment—like rapid EV charging infrastructure—that number is just the tip of the iceberg. Simple plug compatibility is the least of your worries.

Navigating Mexico's Electrical Landscape

While holidaymakers can get by with a simple travel adapter businesses deploying energy assets face a much bigger puzzle. The domestic 127V supply, delivered through the familiar two-pronged Type A and three-pronged Type B sockets, is perfectly fine for charging your mobile phone or laptop. However it is a major bottleneck for commercial-scale projects.

Think of that standard voltage as the final calm trickle of water reaching a home after a long journey through massive city water mains. It is useful but you cannot run a factory with it. For projects that demand serious power, like rapid EV charging stations or grid-scale batteries, you need to tap into the high-pressure mains directly.

For a clearer picture let's compare Mexico's domestic standard with what we are used to in the UK.

Mexico's Electrical Standards at a Glance

This table offers a quick summary of the essential electrical standards for residential and light commercial use in Mexico with a familiar UK comparison.

| Parameter | Standard in Mexico | Common UK Standard (for comparison) |

|---|---|---|

| Voltage | 127V (single-phase) | 230V (single-phase) |

| Frequency | 60Hz | 50Hz |

| Common Sockets | Type A (unearthed), Type B (earthed) | Type G (earthed, fused) |

| Plug Pins | Two flat parallel blades (Type A & B), one round earth pin (Type B) | Three rectangular blades |

As you can see the differences are significant. The lower voltage and different frequency in Mexico mean that simply plugging in UK equipment is not an option without the right hardware.

From Domestic Sockets to Industrial Power

This is where the real challenge begins. Deploying advanced energy solutions means bypassing the domestic supply and connecting directly to higher-voltage tiers of the electrical grid. It is a completely different ball game.

Consider these scenarios:

- Rapid EV Charging: These units are power-hungry. They need high-power three-phase connections that a standard wall socket could never provide especially from constrained grid connections.

- Grid-Scale Batteries: To store and release huge amounts of energy effectively you need a direct high-capacity link to the grid itself.

- Combined On-site Renewables: Integrating solar panels with battery storage requires specialised inverters and management systems to handle the flow of power often at much higher voltages.

Grasping this fundamental difference between domestic and industrial power is the key to successfully launching distributed energy projects in Mexico. It forces a shift in thinking—away from simple adapters and towards robust solutions that bridge the gap between low-voltage availability and high-voltage demand. That is a theme we will be exploring in more detail.

How Power Moves Across Mexico's Grid

To really get a handle on the opportunities in Mexico's energy market you have to look past the standard 127V socket on the wall. The best way to think about the national grid, which is managed by the Comisión Federal de Electricidad (CFE), is as a massive tiered motorway system built for electricity. The power you use every day is travelling down a quiet residential street but its journey started on a high-speed high-voltage super-motorway.

This network uses incredibly high voltages to push electricity across the country's huge distances with minimal fuss. While your office gets 127V the CFE’s main transmission arteries are humming along at levels between 230 kV and 400 kV . Just like high-pressure pipes move water more efficiently this high voltage cuts down on energy loss over long distances. Getting this system to run smoothly and safely depends entirely on top-quality components as covered in a comprehensive guide to electrical fittings and materials.

The Journey from Transmission to Tap

Of course before that high-voltage power can safely run a computer or a coffee machine it needs to be "stepped down" through a series of substations. The voltage is gradually reduced for local distribution networks, which typically operate between 115 kV to 230 kV , before the final drop to the familiar 127V . This whole complex layered infrastructure is exactly why understanding the importance of grid stability is a non-negotiable for any large-scale energy project.

The diagram below shows the final end-user stage of this power journey.

This gives you a sense of the final destination but it is a world away from the high-voltage environment where the journey begins.

Connecting a rapid EV charging hub or a battery storage system is not about using a wall plug; it is about finding the right access point on this high-voltage motorway to draw the necessary power without disrupting local supply.

This tiered system is what makes ambitious projects like rapid EV charging possible. The real challenge is tapping into the right voltage level at the right point. And Mexico’s infrastructure has serious capacity; back in 2004 the CFE's transmission capacity was already 128,841 MVA with distribution capacity at 69,667 MVA . That shows a really robust backbone ready to handle diverse energy demands and it is this capacity that holds the key to unlocking the potential for distributed energy and advanced charging networks across the country.

The Impact on EV Charging Infrastructure

When it comes to electric vehicle charging Mexico’s standard 127V domestic supply creates a fork in the road. For the average home user this voltage is perfectly fine for what is known as Level 1 overnight charging. It is a slow-and-steady approach that comfortably tops up an EV battery for the next day's commute.

But for commercial and public rapid EV charging that low voltage is a serious bottleneck. Think of it like trying to fill a swimming pool with a garden hose; it will get the job done eventually but it is hopelessly inefficient. This is where the real challenge of building a robust public charging network begins.

Level 2 chargers and especially the power-hungry DC rapid chargers demand far more energy than a standard residential circuit can ever deliver. They need a dedicated high-power three-phase connection to pump electricity into a vehicle at a rate that actually makes sense for drivers on the go particularly from constrained grid connections.

Securing High-Power Grid Connections

Getting that kind of power is not as simple as just fitting a new socket. It means entering into a direct and often complicated negotiation with the CFE to secure a medium-voltage connection from the local distribution grid. This process can quickly become both time-consuming and expensive.

The typical steps look something like this:

- Site Assessment: First you have to evaluate if the local grid can even handle the massive extra load of multiple rapid chargers operating at once.

- CFE Application: Then comes the paperwork. You will need to submit detailed plans to formally request a new higher-capacity connection point.

- Infrastructure Upgrades: More often than not the project will require installing a dedicated step-up transformer to convert the available voltage to the levels required by the charging hardware.

These upgrades are not minor tweaks; they add significant cost and complexity to any rapid charging project. Suddenly you have moved from a simple equipment setup to a small-scale construction project that demands specialised electrical engineering and a raft of regulatory approvals.

The core challenge is bridging the gap between the low-voltage power that is readily available and the high-power supply demanded by rapid EV charging. Success hinges on careful planning and direct collaboration with the CFE.

This reality also has a big influence on the design of mobile EV charging solutions. For a simple emergency top-up a mobile unit might be built to use a standard outlet for a low-power boost. But to provide a genuinely rapid charge on the move these mobile systems need their own integrated power source like a large battery allowing them to deliver energy completely independently of any constrained grid connection.

Using Batteries to Overcome Grid Constraints

What happens when you find the perfect spot for rapid EV charging but the local grid just cannot handle the power demand? This is a common roadblock but it is definitely not a dead end. The smart solution is to deploy grid-scale batteries effectively creating your own self-sufficient power hub.

Think of an on-site Battery Energy Storage System (BESS) as a local energy reservoir. It acts as a crucial buffer between the grid and your chargers. The system can slowly sip electricity from a constrained grid during off-peak hours when demand is low storing it up for when it is needed most.

When a stream of EVs pulls in looking for a fast charge the BESS unleashes this stored energy at high power completely sidestepping the local grid’s limitations. This approach means you can avoid expensive and painfully slow grid upgrades which can often stall projects for months if not years. For businesses planning a charger rollout getting to grips with battery-backed EV charging is key to moving projects forward efficiently.

Creating a Resilient Charging Ecosystem

The real magic happens when you pair battery storage with combined on-site renewables like solar panels. Suddenly you have created a resilient and largely self-sufficient charging ecosystem. Solar can charge the batteries during the day slashing your reliance on the grid and dramatically cutting long-term running costs.

To really get a handle on grid constraints and integrate renewables properly you need high-capacity batteries like those from Rolls Surrette Batteries. These systems deliver the storage capacity needed to create a stable reliable power source that is not at the mercy of grid fluctuations.

This combined approach transforms a simple EV charging station into a sophisticated distributed energy resource. It not only serves electric vehicles but can also provide valuable grid support services creating additional revenue streams.

This model is especially relevant for Mexico a country with a long and proud history of investing in its national energy infrastructure. Since the nationalisation of the power sector in 1960 the CFE has overseen a massive expansion of transmission lines and substations. By 2004 Mexico's transmission network already spanned an impressive 44,203 kilometres all built to manage high-voltage power. By using batteries modern projects can work intelligently with this established grid drawing power when it is plentiful and easing the strain when it is scarce.

A Practical Plan for Deploying Your Project

Believe me rushing in without doing your homework is a classic recipe for frustrating delays and ballooning costs.

The first non-negotiable step is always a detailed site assessment. Before you even think about committing to a location you have to get a clear picture of the local grid’s capacity. Is there a medium-voltage connection point right there or are you looking at laying expensive new infrastructure from scratch? This initial check will influence your project's feasibility and budget more than anything else.

Do not put off talking to the CFE. Approaching them early with a well-researched plan shows you are serious and helps to smooth out the notoriously complex approvals process for grid connection.

Your Project Deployment Checklist

Once you have found a viable site the game shifts to meticulous planning and execution. A methodical approach is your best defence against unforeseen problems ensuring all your technical and regulatory bases are covered. Project managers need a clear roadmap to keep everything moving forward.

Here is a practical checklist to guide you:

- Detailed Power Analysis: Nail down your total power requirements. You need to calculate for peak demand scenarios like multiple rapid EV chargers running at once to avoid the costly mistake of under-specifying your connection.

- Certified Equipment Sourcing: Double-check that all your transformers inverters and switchgear are certified for use in Mexico. Critically they must be fully compatible with the country’s 60Hz frequency.

- Regulatory Navigation: Get local experts on your team. They can help you manage the necessary permits and approvals for grid connection which can otherwise be a bewildering and time-consuming process.

- Integrated System Design: If you are combining renewables and batteries a holistic design is essential. To learn more about creating effective energy storage solutions that maximise your efficiency and return on investment we can help.

Still Got Questions?

When it comes to deploying large-scale energy projects in a new country it is natural for questions to pop up. Here are some of the most common ones we hear with straightforward answers to help you navigate the practical side of things.

Can I Use My UK-Bought EV Charger in Mexico?

In short no. A standard UK charger is built for the UK’s 230V/50Hz system which is miles apart from Mexico's 127V/60Hz standard. Trying to plug one in is a recipe for disaster—you risk frying the charger the vehicle or both. For any deployment in Mexico you absolutely must use equipment that is specifically designed for North American electrical standards.

What is the Biggest Hurdle for Installing Rapid EV Chargers?

Almost every time the main challenge is getting a powerful enough grid connection from the CFE Mexico's state utility. While the national grid is solid the local distribution networks can be a different story. In older city centres or more remote spots the local infrastructure often just does not have the capacity to handle a bank of DC fast chargers.

This usually means you are looking at either paying for costly grid upgrades or getting clever with on-site battery storage to manage the energy demand for EV charging from constrained grid connections.

The real sticking point is not just the voltage for Mexico ; it is whether the local grid can deliver the high currents needed minute after minute. This is where combining on-site batteries and renewables really shines as a practical effective solution for EV charging and batteries.

Will My Commercial Equipment Need a Transformer?

It all comes down to what you are plugging in. Standard office gear like laptops and printers will probably be fine with a simple plug adapter. But if you are talking about heavy-duty industrial machinery—including rapid EV chargers brought over from Europe—you will definitely need a properly specified step-up or step-down transformer. It is non-negotiable for ensuring the equipment runs correctly and most importantly safely.

At ZPN Energy , we specialise in turning these grid challenges into opportunities. Our integrated solutions combine rapid EV charging with battery storage mobile EV charging and smart energy management to make your project viable.

See how we can help power your expansion into Mexico by visiting us at https://www.zpnenergy.com.