EV Fleet Charging Solutions: Your Complete Guide

Setting up an EV fleet charging solution is not just about putting a few chargers in the ground. It is about building a reliable and cost-effective energy ecosystem to power your entire commercial operation at scale. This means thinking bigger, integrating everything from rapid EV charging stations and mobile EV charging units to smart energy management systems that can keep you running even when the grid connection is constrained.

Navigating the Future of Fleet Electrification

For UK businesses, the move to an electric fleet is a massive opportunity. But let's be honest, the biggest hurdle is getting dependable, large-scale charging in place. Switching from petrol and diesel is not just about buying new vehicles; it demands a complete rethink of how your business manages and consumes energy.

This guide is designed to give you a clear roadmap for creating a charging strategy that is built to last. We will walk through the essential components for success, starting with the physical hardware and moving all the way to the intelligent systems that bring it all together.

Key Focus Areas for Your Strategy

Our journey will touch on several crucial, interlinked topics every fleet operator needs to get right:

- EV Charging Hardware: We will break down how to choose the right kit for your daily operations, from standard depot chargers for overnight top-ups to rapid hubs that get your vehicles back on the road in minutes.

- Constrained Grid Connections: Many UK sites are stuck with a limited grid connection which can feel like a major roadblock. We will show you how grid scale batteries and combined on site renewables can help you create your own energy independence.

- Smart Energy Management: Finally, we will look at the software that makes it all work, optimising your costs and performance by intelligently managing all your distributed energy assets.

The good news is that you are not going it alone. The UK's national infrastructure is growing fast. By July 2025, the country had already passed 84,000 public charging devices . Crucially for commercial fleets, rapid and ultra-rapid chargers now make up about 20% of that network. This growth, fuelled by both government incentives and private investment, is creating a much stronger foundation for electrification. You can find out more about the UK's EV charging growth on Uswitch.

A truly effective EV fleet charging solution is a complete ecosystem. It combines the right chargers with on-site energy storage and intelligent software to deliver reliable power at the lowest possible cost, regardless of grid limitations.

This guide is all about giving you practical, actionable insights to build a resilient and cost-effective charging operation that will power your fleet long into the future.

Choosing the Right Charging Hardware for Your Fleet

Picking the right hardware is the bedrock of any solid EV fleet charging solutions strategy. This is not about grabbing the shiniest new tech off the shelf; it is about matching the equipment to the day-to-day reality of your operations. Get this right and you will sidestep logistical nightmares and avoid sinking cash into infrastructure you simply do not need.

For most fleets, the depot is the heart of the charging operation and this is where AC chargers truly shine. Think of these units as the dependable workhorses of overnight charging.

An AC charger is like a standard tap steadily filling a large water butt overnight. It is not the fastest method but it is consistent, incredibly cost-effective and gets the job done when time is not a pressing issue. For delivery vans, maintenance vehicles or any asset that returns to base at the end of the day, AC charging is easily the most logical and economical choice.

Understanding Rapid EV Charging

On the flip side, DC rapid chargers are absolutely essential for high-mileage vehicles that cannot afford to be sitting idle for hours on end. If AC chargers are a tap, then DC chargers are a fire hose, designed to blast a vehicle's battery back to full strength in a fraction of the time.

This speed is make-or-break for fleets running on tight schedules or covering huge territories. A long-haul electric lorry or a fleet of private hire vehicles needs to get back out on the road, earning its keep. A rapid EV charging hub can turn a vehicle around in under an hour which is vital for keeping operational uptime and revenue where they need to be.

The key is to 'right-size' your infrastructure. An operation relying solely on slow AC chargers may face crippling bottlenecks, while one filled with expensive DC units might be wasting capital if vehicles are parked for eight hours overnight anyway.

The Rise of Mobile EV Charging

A flexible fleet needs flexible energy solutions and that is exactly where mobile EV charging comes in. These units are, in essence, powerful batteries on wheels, giving you a versatile way to deliver a charge wherever it is needed. Their applications are incredibly varied and solve some very common logistical headaches.

- Emergency Power: If a vehicle runs flat unexpectedly mid-route, a mobile unit can be dispatched for a roadside rescue, avoiding costly recovery services.

- Temporary Sites: For fleets operating at pop-up locations like construction sites or event venues, mobile chargers provide power without digging trenches for permanent infrastructure.

- Capacity Boosting: During peak periods, a mobile charger can supplement your existing depot hardware, helping to manage high demand without needing permanent grid upgrades.

This adaptability makes mobile EV charging a powerful tool for de-risking the transition to electric and adding a welcome layer of resilience to your operations.

Comparison of EV Fleet Charging Hardware

To make an informed decision, it helps to see how these different hardware types stack up against each other. The table below breaks down the key differences to help you match the right charger to your fleet's needs.

| Charger Type | Typical Power Output | Best Use Case | Charging Speed (Typical 50kWh battery) | Infrastructure Impact |

|---|---|---|---|---|

| AC Charger | 7kW - 22kW | Overnight depot charging for return-to-base fleets. | 4-8 hours | Low to moderate. Often uses existing supply. |

| DC Rapid Charger | 50kW - 350kW+ | Quick turnaround for high-utilisation vehicles. | 20-60 minutes | High. Often requires significant grid upgrades. |

| Mobile EV Charger | 20kW - 60kW | Emergency use, temporary sites and demand flexibility. | 1-3 hours | None. It is a self-contained power source. |

As you can see, there is a clear trade-off between speed, cost and intended use. The most effective strategies often blend different charger types to create a system that is both robust and financially sound. This is where smart charging software comes in, optimising this hardware mix to ensure every vehicle gets the right amount of power at the best possible time and price.

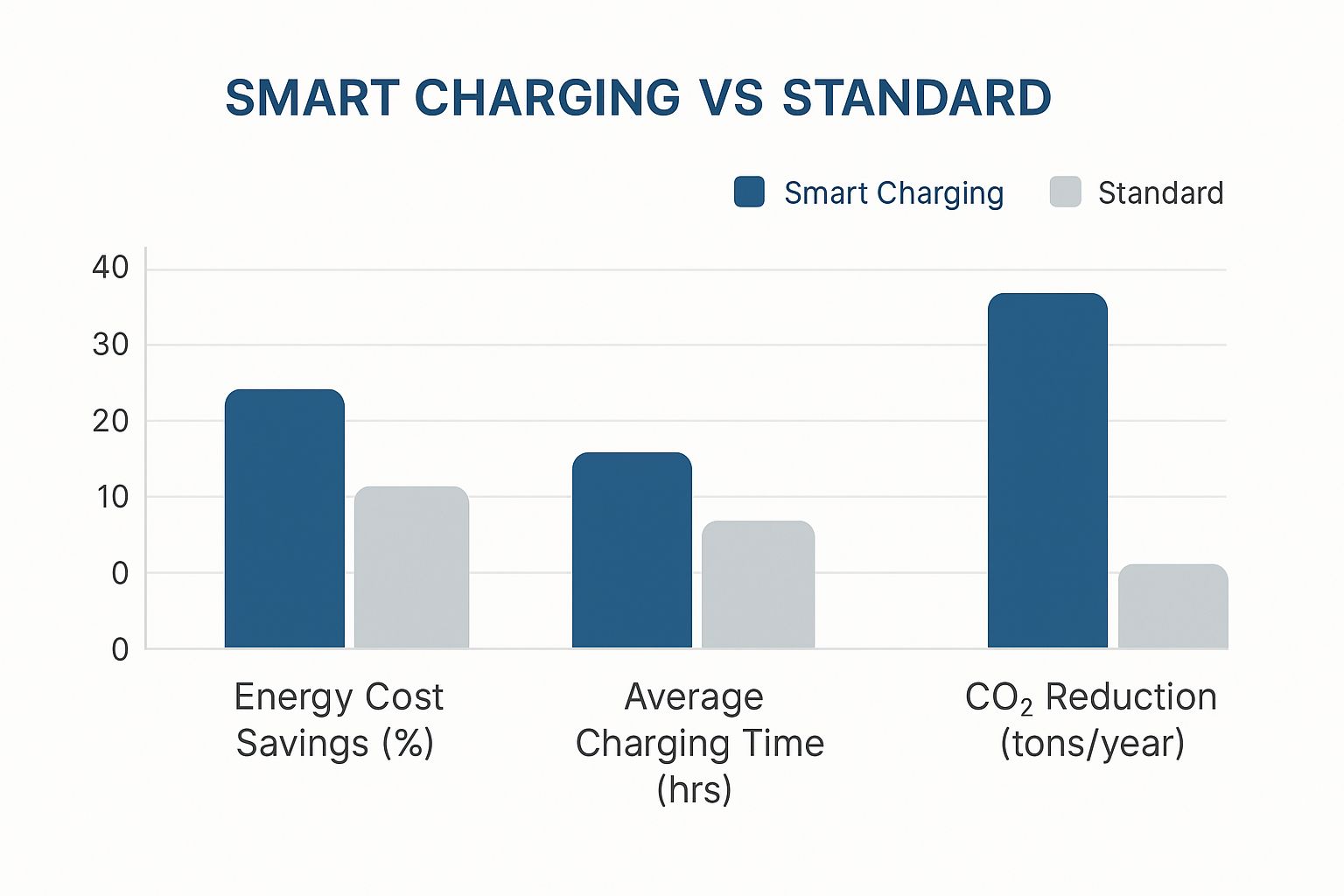

This infographic compares the benefits of using smart charging software against standard charging methods, highlighting potential savings and environmental impact.

The data clearly shows that bringing smart charging into the mix does not just drastically cut energy costs; it also significantly reduces charging times and shrinks the carbon footprint of your fleet.

Solving Grid Constraints with Smart Energy Systems

For many UK businesses, the biggest roadblock to fleet electrification is not the price of the vehicles. It is the local electricity grid. The simple truth is that many commercial and industrial sites just do not have the power capacity to support a large bank of high-powered chargers.

Getting a grid upgrade is one option but it is often an eye-wateringly expensive and painfully slow process. This single issue can stall even the most ambitious EV fleet charging solutions before they even get going.

Thankfully, a weak grid connection does not have to be a deal-breaker. By building a smart, on-site energy ecosystem, you can power a large electric fleet without being entirely at the mercy of the grid. The approach centres on integrating grid scale batteries and combined on site renewables right at your depot.

The UK's public charging network is expanding fast. The number of public chargers grew from 73,334 in January 2025 to 84,218 by July 2025—an increase of nearly 11,000 in just six months. While that is impressive, it also shines a light on the growing strain on our national grid, making it even more critical for businesses to build their own resilient energy systems. You can see the latest data on the official government EV charging map.

The Role of Battery Energy Storage Systems

A Battery Energy Storage System (BESS) is the cornerstone of any strategy to overcome EV charging from constrained grid connections . Think of it as a dedicated energy reservoir for your depot. It acts as a buffer, sitting between your chargers and the grid and completely changes how and when you pull power.

Instead of drawing a massive amount of electricity all at once when your fleet returns for the evening, the BESS can trickle-charge itself slowly during off-peak hours when electricity is cheapest. This stored energy is then unleashed to power your rapid EV charging points during peak times, shielding the grid from sudden, heavy demand.

A BESS effectively decouples your charging schedule from your grid capacity. It lets you deliver high-power charging to your entire fleet using a low-power grid connection, potentially saving you a fortune in upgrade costs.

Creating an Energy Ecosystem with Renewables

Things get really interesting when you combine a BESS with on-site renewables like solar panels. This creates a powerful, largely self-sufficient energy ecosystem and unlocks the true potential of EV charging and batteries .

During the day, your solar panels generate free, clean electricity. This power can be used to run the depot, charge any vehicles that are on-site or—crucially—fill up your battery storage system. That stored solar energy can then be used to charge the rest of the fleet overnight.

This integrated approach delivers several key advantages:

- Energy Independence: You become far less reliant on the grid and volatile energy prices, giving you much tighter control over your running costs.

- Reduced Energy Bills: Using free solar energy to charge your vehicles means exactly what you think it means: significant savings on your electricity bills.

- Enhanced Resilience: If there is a local power cut, your BESS can act as a backup, keeping your fleet on the road and your operations running smoothly.

- Sustainability Credentials: Powering your fleet with your own renewable energy drastically cuts your carbon footprint and strengthens your company's green credentials.

How Distributed Energy Works in Practice

This model is a perfect example of distributed energy , where power is generated and stored precisely where it is needed. It transforms your depot from a simple energy consumer into an active, intelligent energy hub. The system works behind the scenes, managing energy from the grid, your solar panels and the battery to meet charging demand in the most efficient and cost-effective way.

For any fleet manager, getting to grips with https://www.zpnenergy.com/battery-backed-ev-charging is essential. It is more than just a workaround for a weak grid connection; it is a strategic investment that delivers long-term financial returns and operational security. By embracing these smart energy systems, businesses can confidently scale their electric fleets, knowing they have a reliable and affordable power source to support their growth.

Using Smart Software to Optimise Your Charging

If charging hardware and energy storage are the muscles of your EV fleet operation, then intelligent software is the brain. Without it, you are just plugging in vehicles. With it, you are running a coordinated, cost-effective energy ecosystem that actively manages your fleet's power needs.

Smart charging platforms, often part of a wider Distributed Energy Resource Management System (DERMS), act as the command centre for your entire setup. This software automates complex decisions, making sure every vehicle gets the power it needs at the lowest possible cost—all while protecting your site from expensive grid penalties. It is the key to unlocking the full financial and operational potential of going electric.

Automating for Cost Efficiency

The most immediate benefit of smart software is its power to slash your energy bills. It does this by automating charging schedules to sync up with fluctuating electricity prices. Instead of every driver plugging in at 5 p.m. during peak demand (and peak cost), the software takes over.

It knows which vehicles need to be ready first, their current state of charge and the depot’s overall power limit. From there, the system creates a dynamic schedule, charging vehicles when electricity is cheapest—typically overnight. This simple shift in energy consumption can lead to enormous operational savings.

In essence, using smart software to optimise charging is a form of business process automation , where technology handles the heavy lifting to boost efficiency and cut down on manual work.

Smart software transforms charging from a reactive, manual task into a proactive, automated strategy. It ensures your fleet is always ready for its routes while systematically minimising your single largest operational cost: energy.

Mastering Load Balancing to Protect Your Site

One of the biggest risks in charging a large fleet is overloading your site's grid connection. This can lead to tripped breakers, costly downtime and a lot of headaches. Smart software prevents this with a feature called load balancing .

Let's say your site has a total power capacity of 100kW . If ten vehicles, each needing 22kW , plug in at once, the total demand would be 220kW —far more than your limit.

- Without load balancing: The system would likely trip, bringing all charging to a halt and throwing your operations into chaos.

- With load balancing: The software intelligently distributes the available 100kW across all ten chargers. It might prioritise vehicles with urgent departures or give a slower, even charge to all but it will never exceed the site's maximum capacity.

This smart power distribution is vital for any EV fleet charging solutions deployment. It ensures reliability without forcing you into a massive and expensive grid upgrade, making fleet electrification possible even for sites with limited power connections. To see how this works in practice, you can learn more about optimising fleet energy management with ZPN BIZ and HUBz solutions.

Preparing for the Future with Vehicle-to-Grid

Beyond just saving money and protecting your site, smart software is paving the way for the next frontier in fleet energy management: Vehicle-to-Grid (V2G) technology. V2G allows your EVs not just to pull power from the grid but to send it back.

When your vehicles are parked and fully charged, their batteries become a massive, distributed energy resource. Smart charging platforms can manage this two-way flow, allowing your fleet to earn revenue by selling power back to the grid when demand is high.

This has the potential to turn your fleet from a cost centre into a revenue-generating asset. While still an emerging technology, V2G highlights the long-term value of investing in a software-managed charging ecosystem, creating a future-proof foundation for your fleet’s energy strategy.

Planning and Deploying Your Charging Depot

The first steps you take are always the most important. Before you even begin to think about charger types or software, you have to get a handle on your site's power capacity. This initial assessment is fundamental—it dictates the potential scale of your entire operation and flags any immediate constraints you will need to work around.

Proper planning is rooted in a deep understanding of your fleet’s daily life which means digging into the data and analyzing vehicle route history. This information gives you critical insights into daily mileage, vehicle dwell times and real-world energy consumption, all of which are essential for sizing your infrastructure correctly.

Engaging with Your Distribution Network Operator

Here’s a piece of advice: talk to your local Distribution Network Operator (DNO) as early as you possibly can. The DNO manages the electricity grid in your area and you will absolutely need their approval for any new high-power connection. Leaving this conversation until later is a classic, costly mistake that can stall a project for months.

Kicking off a dialogue with the DNO right at the start gives you clarity on the available grid capacity, along with potential costs and timelines for any necessary upgrades. This early engagement is crucial for building a realistic project budget and schedule.

This simple step ensures your plans are grounded in the reality of what the local grid can actually support, preventing nasty surprises down the line. It is a non-negotiable for any serious depot deployment.

Designing an Efficient Depot Layout

The physical layout of your charging depot has a massive impact on your day-to-day operational efficiency. Get it wrong and you are looking at vehicle bottlenecks, slow turnaround times and a higher risk of accidents. A well-designed site, on the other hand, makes the whole charging process seamless.

Keep these best practices in mind when designing your space:

- Vehicle Flow: Map out clear entry and exit routes. You need to allow for easy manoeuvring of your largest vehicles without creating traffic jams.

- Accessibility: Position chargers so they are easy to get to. Make sure there is enough space for drivers to connect their vehicles safely and without hassle.

- Future Expansion: Do not just build for today. Design your depot with future growth in mind, leaving space for more charging bays or for integrating grid scale batteries and solar panels later on.

While the UK’s public network is growing, its per capita charger provision still has some catching up to do compared to other European nations. As of April 2025, the UK averages 113 public chargers per 100,000 residents. This figure is heavily skewed towards London ( 263 ) and Scotland ( 123 ), highlighting a regional imbalance that can complicate logistics for fleets operating nationwide and reinforces the need for robust private depot infrastructure.

Calculating the Total Cost of Ownership

To build a solid business case for your project, you have to look far beyond the sticker price of the hardware. The Total Cost of Ownership (TCO) gives you a much more accurate financial picture by accounting for every expense over the system's entire lifetime.

A comprehensive TCO analysis should always include:

- Hardware Costs: The upfront price of chargers, switchgear and any battery storage systems.

- Installation and Grid Fees: All costs tied to civil works, electrical installation and any grid upgrades required by the DNO.

- Software Subscriptions: Ongoing fees for the smart charging and energy management platforms that keep your system running optimally.

- Maintenance and Support: The long-term costs of keeping both your hardware and software in top condition.

This holistic view provides the financial clarity needed to secure investment and ensures your EV fleet charging solutions are built on a sustainable foundation.

Building Your Fleet Electrification Strategy

Switching your fleet to electric power is not about just buying some new hardware. It is about building a complete strategy from the ground up. The real key to a successful EV fleet charging solutions deployment is knitting together the right charging infrastructure, smart energy systems and intelligent software into a single, seamless operation. Think of it as creating a resilient and efficient energy ecosystem for your business.

The journey starts by matching charging hardware to your fleet’s real-world, daily needs. This usually means a smart blend of cost-effective AC chargers for overnight depot charging combined with high-power rapid EV charging for those vehicles that need to get back on the road fast. Getting this balance right prevents both operational bottlenecks and wasted investment.

Integrating Smart Energy for Resilience

Next up, you have to tackle the grid. For many businesses across the UK, a constrained grid connection is the single biggest roadblock to electrification. This is where smart energy solutions come in.

By integrating on site renewables with grid scale batteries , you can create your own self-sufficient energy hub. This approach, using EV charging and batteries together, not only gets you around grid constraints but also dramatically cuts energy costs and makes your operations far more resilient to local power outages.

This combination of distributed energy assets transforms your depot from just another building pulling power from the grid into an active, intelligent energy hub.

Finally, a sophisticated management software layer brings all these elements under control. This is the brain of the whole operation. It automates charging schedules to take advantage of the cheapest electricity tariffs and uses load balancing to make sure you never overload your site’s electrical supply. It is what guarantees your fleet is always charged and ready for duty at the lowest possible cost.

When you look at fleet electrification through this lens—as a strategic investment in long-term efficiency and success—the path forward becomes much clearer. To see how an integrated approach can directly benefit your operation, you can learn more about why fleet operators should switch to ZPN for EV infrastructure. By embracing this model, you are not just adopting new technology; you are building a future-proof foundation for your entire business.

Your Fleet Charging Questions, Answered

Making the jump to an electric fleet always sparks a few questions. We get it. Here are some straightforward answers to the queries we hear most often from fleet managers, focusing on the real-world nuts and bolts of building EV fleet charging solutions that actually work.

What is the Biggest Hurdle When Installing Fleet Chargers?

Nine times out of ten, the single biggest obstacle is the local grid connection. It is a simple but frustrating reality: many commercial sites just do not have enough power on tap to run a bank of rapid EV charging points without a serious—and seriously expensive—grid upgrade from the local Distribution Network Operator (DNO).

This is exactly why you need to be talking to your DNO from day one. It also shines a spotlight on the huge advantage of pairing EV charging and batteries . With an on-site Battery Energy Storage System (BESS), you can trickle-charge the battery from a weaker grid connection over time then unleash that stored power to charge vehicles rapidly. It is a clever way to sidestep the EV charging from constrained grid connections bottleneck entirely.

Should I Install All Fast Chargers or Mix Different Speeds?

A mix of charger speeds is almost always the smartest and most cost-effective way to go. While rapid EV charging is non-negotiable for high-mileage vehicles that need to get back on the road quickly, it is often complete overkill for vehicles parked up overnight for eight hours or more.

A blended approach is best. Use slower, cheaper AC chargers for your overnight depot charging and keep the powerful, more expensive DC rapid chargers for vehicles on tight schedules. This 'right-sizing' of your infrastructure ensures you meet all your operational needs without sinking unnecessary cash into hardware.

How Does Battery Storage Actually Save My Fleet Money?

On-site battery storage is a game-changer for your bottom line, delivering savings in several key ways. By integrating grid scale batteries into your depot, you take back control over your energy costs and build a much more resilient operation.

Here’s a quick breakdown of how it works:

- Tariff Arbitrage: The battery charges up during off-peak hours when electricity is cheap. It then discharges that low-cost energy to power your fleet during peak times when prices are highest.

- Peak Shaving: It helps you dodge hefty demand charges from your energy supplier. Instead of drawing a massive amount of power from the grid all at once, you use the energy stored in your battery.

- Renewable Integration: If you have got on site renewables like solar panels, the battery stores all that free, clean energy generated during the day. You can then use it whenever you need it, cutting your reliance on the grid even further.

This approach to distributed energy effectively turns your depot into a smart energy hub that actively works to drive down your operating costs.

Ready to build a resilient and cost-effective charging strategy for your fleet? ZPN Energy is the UK's leading expert in rapid charging, battery storage and integrated energy management systems. Discover our complete EV fleet charging solutions at https://www.zpnenergy.com.