A Guide to Zero Waste to Landfill for UK Energy Firms

Zero waste to landfill isn't just about recycling more. It's a complete business strategy aimed at diverting at least 90% of a company's waste away from the rubbish tip. Think of it as a top-to-bottom overhaul achieved by reducing waste at its source, finding ways to reuse materials and then applying intensive recycling and energy recovery for whatever is left.

Why Zero Waste to Landfill is a Strategic Imperative

For businesses at the sharp end of the EV charging and distributed energy sectors, committing to zero waste is no longer just a nice-to-have environmental badge. It’s a powerful commercial strategy, plain and simple, driven by real financial gains and what the market now expects. This approach forces a fundamental rethink of how materials flow through an organisation, from the moment they arrive to the day they're disposed of.

Adopting this mindset means you start looking at everything differently—from the packaging on a new batch of rapid EV chargers to the end-of-life plan for grid-scale batteries. Instead of seeing discarded materials as a costly headache, a zero-waste policy reframes them as valuable resources just waiting to be recovered.

The Commercial Drivers for Change

The push for this strategy comes from several directions, blending financial sense with brand reputation. Companies that get out in front on this often find they've unlocked significant competitive advantages that strengthen their bottom line and their standing in the market.

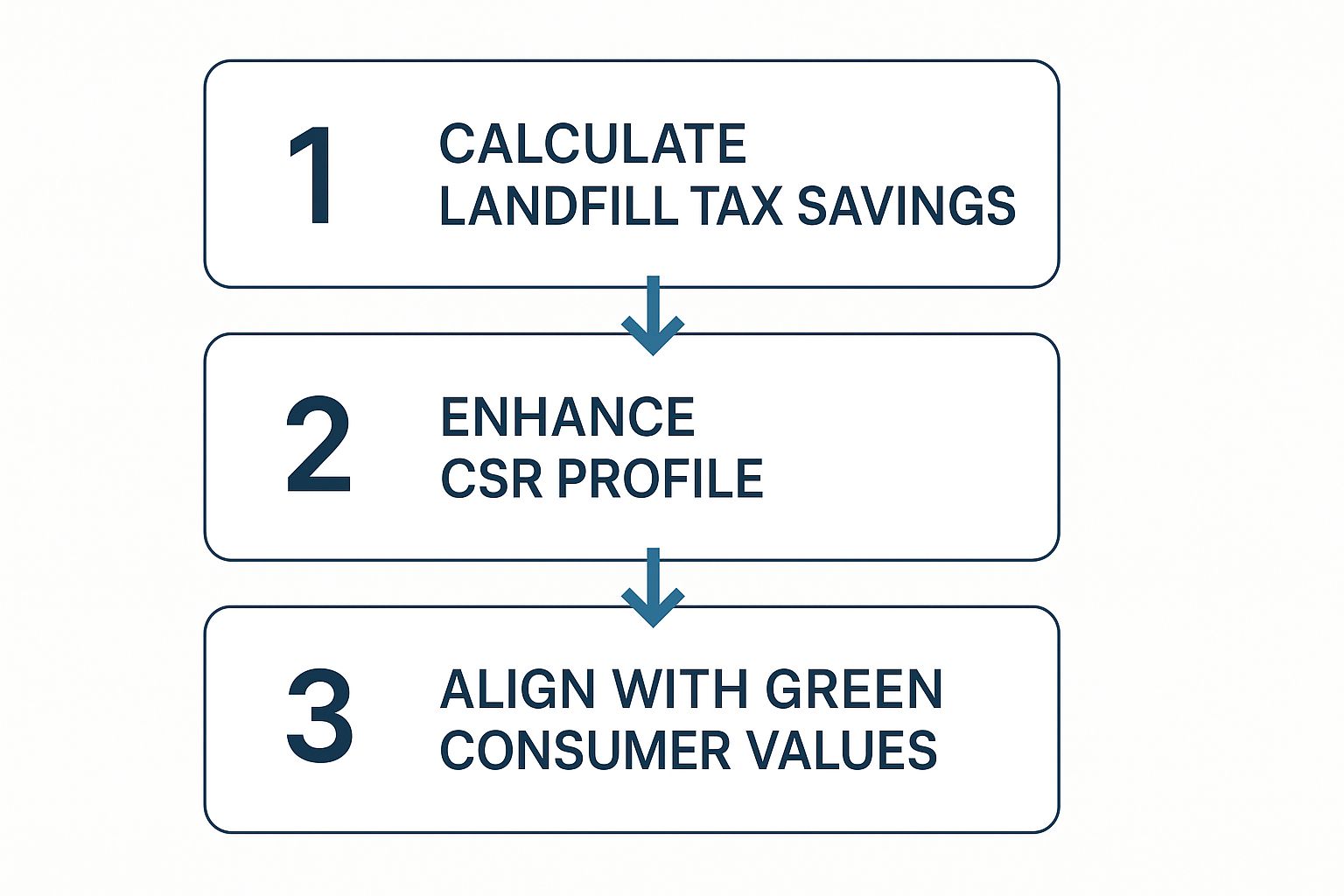

It boils down to a few key benefits:

- Significant Financial Savings: The most obvious win is avoiding eye-watering landfill taxes. As disposal costs continue to climb thanks to regulatory pressure, every tonne of waste you divert from landfill is a direct saving on your operational expenses.

- Enhanced Corporate Social Responsibility (CSR): A genuine, verifiable commitment to zero waste seriously boosts your company's CSR profile. This makes you far more attractive to investors, partners and the kind of top talent that wants to work for a company that takes sustainability seriously.

- Meeting Green Consumer Demand: Today’s customers and corporate clients are actively choosing businesses that demonstrate real environmental stewardship. A zero-waste policy sends a clear signal that your values are in step with theirs. You can see how we put this into practice by exploring how our solutions support a carbon neutral economy: https://www.zpnenergy.com/how-zpn-energys-solutions-support-a-carbon-neutral-economy.

This isn’t just a random list of perks; they all build on each other to create a compelling business case.

As the graphic shows, the journey often kicks off with direct cost savings. This in turn fuels a stronger corporate image, which ultimately helps you win over and retain environmentally conscious customers.

Regulatory and Market Pressures

Across the UK the direction of travel is unmistakable. Government bodies and major businesses are making zero waste to landfill a priority. While it might not be a legal requirement across the board just yet, it’s clear where things are headed. The smart companies are getting ahead of the curve now, running robust waste audits and upgrading their recycling systems before stricter regulations come into force. The payoff is twofold: reduced landfill taxes and a stronger, more responsible corporate image.

Recognising this as a strategic imperative also means understanding the bigger picture of the circular economy. For example, considering the environmental benefits of buying refurbished mobile phones highlights how extending product lifecycles contributes to wider environmental health. For companies installing mobile EV charging units or managing distributed energy assets, getting to grips with these concepts is no longer optional—it's essential for long-term resilience and growth.

How to Conduct Your First Waste Audit

Embarking on a zero waste to landfill journey really begins with one critical step: a thorough waste audit. Think of it as a detailed stocktake of everything your business throws away. Before you can reduce your waste, you have to get a handle on exactly what you’re producing, where it’s coming from and where it all ends up. This process gives you the essential baseline data you need to build a strategy that actually works.

For a company in the EV charging or distributed energy space, this means looking far beyond the typical office rubbish bin. The scope has to include everything from the large wooden crates used to ship rapid EV charging units to the plastic wrapping around grid-scale batteries and the electronic waste from decommissioned hardware. It’s only by creating this complete picture that you can spot your biggest opportunities for change.

Preparing for Your Audit

Good preparation is what makes or breaks an audit. The goal is simple: to safely collect, analyse and record every single piece of waste generated across a representative period. This could be a day, a week or even a month, depending on your operational cycle. You'll need to pull together a small team and get them the right safety gear—gloves, goggles and high-visibility vests are a must, especially for site-based audits.

Next you need to define the scope. Are you going to start with a single site, like a warehouse where new EV charging hardware is stored? Or will you audit a mobile installation team’s daily waste? Starting small often makes the whole process feel much more manageable before you decide to scale it up.

Here are the essential steps to get ready:

- Define the Audit Period: Pick a timeframe that accurately reflects your typical business operations.

- Assemble Your Team: Designate a few people who will be responsible for collecting and sorting the waste.

- Gather Your Tools: This includes scales to weigh everything, clear bags for sorting different materials and a spreadsheet or software to log all the data.

- Communicate with Staff: Let all relevant personnel know about the audit, its purpose and how it will be conducted. This is key to getting their cooperation.

Executing the Audit and Analysing the Data

With preparations sorted, the hands-on phase begins. Your team will collect all the waste generated within your defined audit period and location. But instead of it all going straight into the general waste skips, the materials are brought to a designated sorting area. Here the team meticulously separates everything into distinct categories like cardboard, soft plastics, metals, electronic components and general non-recyclable waste.

Each category is then weighed and the results are carefully recorded. This granular data is where the real insights are hiding. You might discover that 70% of your site waste by weight is just packaging for new charging units, or that a significant amount of copper wiring from old installations is being thrown out instead of recycled.

A waste audit isn't just about measuring rubbish; it's about uncovering inefficiencies. It transforms abstract goals into concrete, actionable data, showing you precisely where to focus your efforts for the greatest impact on your zero waste to landfill targets.

This process provides a clear, data-driven baseline. It moves you from guesswork to an informed position, enabling you to set realistic reduction targets. For instance, if your audit reveals a huge volume of single-use plastics from component packaging, you can immediately start a conversation with your suppliers about better alternatives. The audit literally illuminates the path forward, turning your zero-waste ambition into a structured, achievable plan.

To help you get started, we've identified some of the most common waste streams you're likely to encounter in the EV and energy sector.

Key Waste Streams in EV and Energy Infrastructure

| Waste Stream | Common Sources | Recommended Diversion Strategy |

|---|---|---|

| Packaging Waste | Cardboard boxes, wooden pallets/crates, plastic shrink wrap, polystyrene foam inserts for chargers and batteries. | Partner with suppliers for returnable/reusable packaging programmes. Segregate for specialist recycling. |

| Electronic Waste (E-Waste) | Decommissioned EV chargers, old inverters, circuit boards, communication modules and control systems. | Engage certified e-waste recyclers to recover valuable metals and dispose of hazardous components safely. |

| Scrap Metal | Off-cuts of copper wiring, aluminium mounting hardware, steel enclosures from retired equipment. | Segregate by metal type (copper, aluminium, steel) and sell to scrap metal recyclers. |

| Plastic Waste | Cable insulation stripping, plastic conduits, protective films on components, single-use packaging. | Identify plastic types (e.g., PVC, HDPE) for targeted recycling streams. Explore options for closed-loop recycling. |

| General Construction Debris | Concrete from foundation work for constrained grid connections, excavated soil, off-cuts of construction materials. | Work with construction partners who practise waste segregation. Reuse soil where possible and send concrete for crushing. |

| Hazardous Waste | Spent grid-scale batteries (if not returned to manufacturer), used oils or coolants from equipment maintenance. | Strict adherence to hazardous waste regulations. Use licensed disposal contractors. |

By categorising your waste like this during the audit, you'll be able to quickly pinpoint the most significant sources and prioritise the diversion strategies that will make the biggest difference.

Building Your Zero Waste Implementation Plan

Right, you’ve done the hard work of the waste audit. You have the data. Now it's time to turn those numbers and observations into a proper, practical strategy. This is where you build a plan that moves your business from simply tracking waste to actively eliminating it. A successful zero waste to landfill plan isn't a vague ambition scribbled on a whiteboard; it's a detailed roadmap with clear, measurable targets. Everyone needs to know what their role is.

Think of this plan as your organisation's central guide. It doesn't just outline what you want to achieve but explains exactly how you're going to get there, breaking a massive goal into smaller, manageable chunks.

Setting Realistic and Measurable Targets

First things first: you need to define what success actually looks like. A woolly goal like "reduce waste" just won't cut it. You need specific, measurable, achievable, relevant and time-bound (SMART) targets. For an EV charging company like ours, that might mean aiming to divert 90% of all operational waste from landfill within 24 months .

It helps to break that main goal down into smaller milestones:

- Year 1 Goal: Hit a 70% diversion rate. We can do this by focusing on the low-hanging fruit—the high-volume waste streams like packaging from our rapid EV chargers and grid-scale batteries.

- Year 2 Goal: Push that up to 90% . This means tackling the trickier stuff, like electronic components and mixed materials from site installations that combine renewables, EV charging and batteries.

These targets create a sense of accountability and give you a clear benchmark to measure your progress against. Suddenly the abstract concept of zero waste becomes a concrete business objective.

Engaging Suppliers and Specialist Partners

Here’s a simple truth: you can't achieve zero waste on your own. A huge chunk of your waste, especially packaging, comes from your supply chain. So getting your suppliers on board isn't just a good idea; it’s absolutely essential. Start talking to them about cutting down on unnecessary packaging, switching to recyclable materials or even setting up take-back schemes for things like delivery crates and pallets.

For the more complex items—think end-of-life batteries from mobile EV charging units or old circuit boards—you'll need to find specialist recycling partners. These are the firms with the right tech and certifications to handle hazardous materials and pull out valuable resources, keeping you compliant and feeding into the circular economy. For a bit more on this, there are some great guides on How Businesses Can Achieve Zero Waste to Landfill.

Creating a Clear Roadmap

Your roadmap should be all about priorities. Not all actions are equal. You need to figure out what will give you the biggest bang for your buck. Some initiatives will deliver quick wins, which is great for building momentum and showing the value of the project early on. Others will be longer-term strategic projects.

A well-structured implementation plan acts like a navigation system. It plots the most effective route to your zero waste to landfill destination, ensuring you prioritise high-impact actions without losing sight of the final goal.

Despite all the talk of progress, the UK still sends millions of tonnes of municipal waste to landfill every year. In a recent year, around 11.2 million tonnes of municipal waste were landfilled . That’s a staggering loss of valuable materials and a huge missed opportunity for the environment. This is exactly why a clear, actionable plan is so urgent for businesses.

By combining ambitious targets with strong partnerships and a clear, prioritised roadmap, your company can make the shift from simply managing waste to systematically eliminating it. This strategic thinking doesn't just apply to waste, either; it’s central to broader goals and you can see how these principles connect when you're unlocking the power of smart energy management with ZPN.

Using Technology for Advanced Waste Diversion

Hitting an ambitious zero waste to landfill target, especially in a complex field like energy infrastructure, means going way beyond just putting out a few recycling bins. It demands a sharp focus on the tricky waste streams that are unique to our industry. Technology is what unlocks the more advanced methods, turning potential headaches like old batteries and electronics into genuinely valuable resources.

This is all about embracing specialised processes that can dismantle complex products and pull out the raw materials locked inside. For companies working in EV charging and battery storage, this isn't just an environmental box-ticking exercise; it's a real commercial opportunity to get involved in the circular economy.

Advanced Battery Recycling and Material Recovery

Lithium-ion batteries are the lifeblood of the modern energy transition, powering everything from rapid EV chargers to huge grid-scale storage systems. But what happens when they reach the end of their life? That’s a serious challenge. Tossing them into a landfill is simply not an option—it’s incredibly wasteful and an environmental hazard.

This is where advanced battery recycling comes in. These technologies are built to tackle this problem head-on, moving far beyond simple disposal to focus on recovering high-value materials.

- Pyrometallurgy: Think of this as a high-tech smelting process. It uses intense heat to melt down the batteries, burning off plastics and separating out a metallic alloy packed with valuable stuff like cobalt, nickel and copper.

- Hydrometallurgy: This is a less energy-hungry approach that uses water-based solutions to chemically leach metals from the battery's "black mass" (the crushed-up internal components). A key benefit here is its ability to recover a high percentage of lithium, which can often be lost in the smelting process.

By teaming up with specialist recyclers who use these methods, companies can ensure that up to 95% of the critical minerals from their old grid-scale batteries are recovered and fed back into the supply chain. This immediately cuts our reliance on new mining and helps build a more resilient source of raw materials for making future batteries.

Managing E-Waste from Charging Hardware

EV technology is moving fast, which means charging hardware—from mobile EV charging units to control systems—can become outdated sooner than we'd like. This electronic waste or e-waste is a fast-growing problem that needs careful handling to keep hazardous materials out of our environment. A true zero waste strategy has to do more than just bin it.

The smartest way to handle e-waste is to stop seeing it as rubbish and start seeing it as an inventory of reusable parts. Refurbishment and component harvesting are the best ways to divert this waste, extending the life of valuable materials and reducing the need to manufacture new ones.

Instead of scrapping an entire rapid EV charger that's a bit behind the times, a refurbishment programme can give it a second chance. This could be as simple as a software upgrade or replacing a few worn parts before redeploying it in a less demanding spot. For hardware that's truly beyond saving, component harvesting allows technicians to salvage perfectly good parts like circuit boards, power modules and connectors to be used for repairs on other units.

Innovative Waste-to-Energy Solutions

What about the small amount of waste that really can't be reused or recycled? Even for this there are innovative conversion technologies that offer one final route away from landfill. These methods help create a truly circular system where even the toughest materials can be used to generate value.

Waste-to-energy (WtE) processes, like gasification or pyrolysis, use extremely high temperatures in a controlled environment to convert non-recyclable waste into a synthetic gas or "syngas". This gas can then be used to generate electricity, effectively turning leftover rubbish into a fuel source. This is a great fit for managing mixed, non-hazardous waste from installation sites or operational facilities where it's just not practical to sort everything for recycling. These solutions can even be combined with on-site renewables to create a self-sustaining distributed energy system.

As companies in our sector look to make every part of their operation more efficient, they should also look into the role of AI and big data in revolutionizing energy management. The same data-driven thinking can be applied to get smarter about waste analytics too.

Engaging Your Team and Communicating Success

You can have the best technology and the sharpest strategy, but getting to a genuine zero waste to landfill status really comes down to your people. A successful programme lives or dies on company-wide buy-in. Without a team that understands and believes in the mission, even the best-laid plans will stumble.

This all starts with clear, consistent internal communication. It’s not enough to just put out some new bins and fire off a memo. You need to build a real culture of sustainability where every team member feels they have a part to play—from the engineers installing rapid EV chargers on-site to the office staff keeping operations running smoothly.

Fostering a Culture of Sustainability

Building this culture is about more than just giving instructions; it’s about education and motivation. Your team needs to understand the ‘why’ behind any new procedures. It's crucial to connect the company’s zero waste goals to the bigger picture of environmental responsibility and, just as importantly, the commercial wins for the business.

Practical training is non-negotiable. This needs to be hands-on and tailored to different roles across the company.

- For Installation Teams: Give them clear, simple guidance on segregating waste at the point of installation. This means separating packaging from mobile EV charging units, managing off-cuts from constrained grid connection work and handling old components correctly.

- For Warehouse Staff: Train them on how to break down packaging from things like grid-scale batteries for recycling. Show them how to spot opportunities to reuse delivery materials that come through the door.

- For Office Personnel: The focus here should be on correctly sorting day-to-day waste, cutting down on paper and encouraging the use of reusable cups, containers and stationery.

Consider appointing 'Waste Champions' within different departments. These people become the go-to experts for their colleagues, keeping enthusiasm high and making sure new ways of working are actually followed.

Communicating Your Achievements Externally

Once you start hitting your targets, shout about it. This isn't just about patting yourselves on the back; it's about building trust and showing your commitment to customers, investors and the wider public. Transparency is everything here.

Your zero waste to landfill journey is a powerful story. Sharing it authentically can set your brand apart in a crowded market, turning a cost-saving initiative into a compelling marketing asset that clicks with environmentally conscious clients.

Use sustainability reports to lay out your progress, including honest data on diversion rates and waste reduction. For a business in the EV charging and distributed energy world, this level of detail demonstrates operational excellence and a forward-thinking attitude.

Certifications like ISO 14001 or becoming a certified B Corp can offer third-party validation of your hard work, adding real weight to your claims. Make sure these achievements are highlighted on your website, in marketing materials and when you’re tendering for new business.

The UK has been making real progress, with biodegradable municipal waste sent to landfill falling from 6.3 million tonnes to 5.3 million tonnes in a recent year. This is being driven by better recycling rates, with Wales leading the way at 57.0% . By sharing your company's contribution to this national effort, you align your brand with a positive, large-scale movement. You can dive into the complete waste data from the UK government to learn more.

Overcoming the Inevitable Bumps in the Road

Let's be realistic: switching to a zero waste to landfill policy is a major commitment. Like any big operational change, it’s going to have its challenges. Knowing what these hurdles are ahead of time is the best way to keep your momentum without disrupting the core business of EV charging and energy management.

One of the first things that trips companies up is the initial investment. New sorting bins, specialist balers for compressing cardboard and plastics and the time needed for staff training all have an upfront cost. It’s crucial, though, to see this as a long-term investment, not just an expense. The payback comes from slashing your landfill taxes and bringing down those ever-rising waste management fees.

Dealing With the Tricky Stuff

For a business like ours, managing complex and sometimes hazardous waste is a particularly thorny issue. Finding reliable partners to handle things like end-of-life grid-scale batteries or old electronic parts from retired rapid EV chargers can feel like a huge task. The market for specialist recyclers is getting bigger, but you have to do your homework to make sure they're properly certified and following all UK regulations.

Then there's the problem of contamination. A single batch of mixed recycling can be flat-out rejected if it’s tainted with the wrong materials—think oily rags tossed in with clean cardboard at an installation site. This doesn't just set you back; it can also lead to fines from your waste contractor.

The journey to zero waste isn't about getting everything perfect on day one. It’s about building a solid, resilient system that can cope with real-world problems, from a contaminated bin to the logistics of managing waste created by mobile EV charger installation teams.

Practical Fixes and Getting Ahead of the Game

The best way to tackle these issues is to be proactive. The solutions nearly always come down to good planning and strong partnerships, which can turn potential roadblocks into straightforward tasks and actually strengthen your zero waste commitment.

Here are a few pragmatic steps to get you started:

- Invest in Phases: Instead of one massive upfront cost, roll out new equipment and processes one site at a time. You can use the savings generated from the first site to help fund the next one.

- Vet Your Suppliers: Do your research. Build proper relationships with certified recyclers who can handle specialised waste like batteries. Ask for their documentation and, if you can, audit their processes to ensure they're up to scratch.

- Keep Training Clear and Simple: Fight contamination with focused training. Use clear, visual guides on all your bins and give regular, role-specific advice to your teams—especially those out in the field working on distributed energy projects or from constrained grid connections. Make sure everyone knows exactly what goes where.

Your Questions Answered: Getting to Zero Waste to Landfill

Rolling out a zero waste to landfill strategy always brings up a few practical questions, especially for businesses in technical fields like EV charging and distributed energy. Let's tackle some of the most common ones we hear from UK companies.

What's the Real Difference Between 'Zero Waste' and 'Zero Waste to Landfill'?

It’s a common point of confusion but the distinction is important. People often use the terms interchangeably but they represent two different goals.

'Zero waste' is the big, aspirational philosophy. It’s about completely redesigning how products are made and used so that everything is reused and nothing is ever thrown away. Think of it as the ultimate ideal—a circular system with no end-of-life.

'Zero waste to landfill', on the other hand, is a much more practical and achievable target for most businesses today. It focuses on diverting a huge chunk of your waste—typically 90% or more —away from being buried in the ground. For an EV charging company, that means creating robust processes for recycling, composting and recovery for everything from the packaging on new rapid chargers to old equipment pulled from a grid-constrained site.

Isn't This Going to Be Expensive for My Business?

There are some upfront costs, that’s true. You might need to invest in new, clearly labelled bins, run some staff training sessions or set up contracts with specialist waste handlers. But look at the bigger picture. The long-term savings often cancel out these initial costs and then some.

The most immediate win comes from dodging the ever-increasing landfill taxes and cutting down your standard waste collection bills. Many UK companies find the whole initiative pays for itself over time. Plus, getting smart about waste segregation often uncovers hidden value. Suddenly you might realise you have streams of scrap metal from EV charging from constrained grid connections or old electronics that can be refurbished and sold, creating brand new revenue.

How Do We Deal with Hazardous Waste Like Old Batteries?

This is non-negotiable: hazardous waste needs a specialist. For things like end-of-life grid-scale batteries or the power packs from your mobile EV charging units, you must work with accredited recycling partners. These are the experts equipped to safely break down components and extract valuable materials like lithium and cobalt, all while staying compliant with strict UK environmental laws.

Your waste audit is the critical first step. It must correctly identify all hazardous streams, from grid-scale batteries and electronic circuit boards to used coolants, allowing you to establish the correct and legally compliant disposal pathways from the very beginning of your programme.

Getting this right isn't just about ticking a compliance box. It’s about actively feeding into the circular economy, turning what could be a dangerous waste product back into a valuable resource for UK manufacturing.

At ZPN Energy , we integrate sustainability into the core of our operations, from developing rapid charging infrastructure to deploying advanced battery storage. Discover how our energy management solutions can support your business's environmental and commercial goals by visiting https://www.zpnenergy.com.