A Business Guide to Rapid Chargers for Electric Cars

A rapid charger for an electric car is a high-power unit designed to top up an EV's battery in minutes, not hours. Often called DC fast chargers, these systems are what make long-distance EV travel possible and keep high-use commercial fleets on the road. They’re a world away from the slower AC chargers you might find at home or the office.

The Rapid Charger Revolution in UK Business

The UK’s transport world is changing and the rapid charger for electric cars is right at the heart of it. For businesses, these units are no longer a nice-to-have; they're becoming a critical piece of infrastructure.

From retail parks looking to attract EV-driving customers to logistics depots ensuring electric vans stay on schedule, high-speed charging is now a commercial necessity. The power to add hundreds of miles of range in the time it takes a driver to grab a coffee fundamentally changes the game for electric fleets.

This shift is picking up speed. The UK has seen a huge expansion of its charging network, with a clear focus on getting faster.

The number of ultra-rapid chargers ( 150kW or higher) shot up by 23% in the last year, now standing at around 8,619 units . For the first time, these have overtaken the number of standard rapid chargers, showing a clear market shift towards slashing charging times.

The demand is undeniable, with ultra-rapid charger use soaring by 58% in the first half of this year alone. You can find out more about the expansion of EV charging in the UK.

Overcoming the Grid Connection Challenge

But there’s a big hurdle. For many UK businesses, deploying a rapid charger runs into the major challenge of the local grid connection. These powerful units demand a huge amount of electricity, putting immense strain on an infrastructure that often wasn't built for such loads. This is especially true for commercial sites with already limited grid capacity.

This guide will dig into this core problem.

More importantly, it will focus on the clever solutions that make widespread rapid charging not just possible but profitable. These include:

- Mobile EV Charging: Giving you flexibility and deployment without digging up the car park.

- Grid Scale Batteries: Storing energy to unleash during peak charging demand.

- Combined On-site Renewables: Using solar power to generate your own clean, cheap electricity.

- Distributed Energy Management: Building a smart, self-sufficient energy ecosystem on your site.

By combining EV charging with battery storage, businesses can break free from grid limitations. A potential roadblock is transformed into a strategic energy asset and a powerful new revenue stream.

How Rapid and Ultra-Rapid Charging Really Works

If you're thinking about installing a rapid charger for electric cars, it’s essential to get your head around the technology that delivers that incredible speed. It all comes down to understanding the different power levels and what they mean for performance in the real world—whether for your fleet or your customers.

At its heart, charging power is measured in kilowatts ( kW ). Think of it like water pressure: the higher the kW, the faster you can fill an EV’s battery. It’s that simple. This is the fundamental difference behind all those advertised charging speeds.

AC vs DC: The Critical Difference

The single most important distinction in EV charging is between Alternating Current (AC) and Direct Current (DC). Here’s the key thing to remember: all batteries, including those in EVs, store energy as DC. But the national grid supplies power as AC.

-

AC Charging (Slow/Fast): With a slower charger (typically up to 22kW ), the car does all the hard work. AC power flows from the grid into the vehicle, where a small on-board converter changes it to DC to fill the battery. The charging speed is bottlenecked by the size and power of this internal converter, which varies wildly from one EV model to the next.

-

DC Charging (Rapid/Ultra-Rapid): This is where things get clever. A rapid charger has a huge, powerful converter built right into the unit itself. It pulls AC power from the grid, converts it to DC on the spot and feeds it directly to the EV’s battery. By bypassing the car's slow on-board converter, it can deliver much higher power levels for dramatically faster charging.

If you want to get into the nuts and bolts of the technology, our ultimate guide to rapid DC EV charging breaks down exactly how these systems operate.

Power Tiers and What They Mean on the Road

Rapid charging is broken down into tiers based on power output and this directly translates to how quickly a driver can get back on their journey. Choosing the right tier is crucial for matching the infrastructure to your site’s needs.

To make sense of it all, here's a simple comparison of the main rapid charging categories and what they offer.

Comparing Rapid and Ultra-Rapid EV Chargers

| Charger Type | Power Output (kW) | Typical Time to 80% Charge | Approx. Range Added per 30 mins | Ideal Commercial Use Case |

|---|---|---|---|---|

| Rapid | 50kW - 149kW | 40 - 60 minutes | 80 - 100 miles | Retail sites, car parks and depots where drivers might stay for a while. |

| Ultra-Rapid | 150kW - 350kW+ | 15 - 30 minutes | 150 - 250+ miles | Motorway services, dedicated charging hubs and high-turnover fleets needing quick refuels. |

These numbers are a complete game-changer for commercial operations. An ultra-rapid 350kW charger can add over 200 miles of range in the time it takes for a coffee break, making the experience almost identical to a traditional petrol station stop.

This table highlights just how much of a leap ultra-rapid charging is, offering speeds that truly support long-distance travel and high-utilisation commercial fleets.

Getting to Grips with UK Connector Types

Finally, a rapid charger for electric cars is useless without the right physical plug. Thankfully, the UK market has largely settled on a couple of key standards for DC charging.

The Combined Charging System, or CCS (Combo 2) , is now the dominant standard for almost every modern EV sold in the UK and Europe. It cleverly combines the AC connector with two large DC pins below it, all in a single, versatile plug.

The only other main type you might still see is CHAdeMO , which was favoured by early Japanese models like the Nissan Leaf. While there are still plenty on the road, most new EVs now ship with CCS ports. For any new installation, focusing on CCS is the most future-proof decision you can make. Knowing which connectors your target customers or fleet vehicles use is the final piece of the puzzle.

Navigating Grid Connection Challenges

Thinking about installing a rapid EV charger? It’s rarely as simple as buying a unit and plugging it in. For most businesses in the UK, the single biggest—and most expensive—hurdle is the local grid connection. This one factor often makes or breaks a project, determining whether it’s financially viable or gets buried under crippling delays and costs.

Many commercial sites, especially older industrial estates or those in rural spots, just weren't built for the enormous power demands of high-speed EV charging. The existing electrical infrastructure simply doesn't have the capacity. This is what we call a constrained grid connection and it's a massive roadblock.

To put it in perspective, a single 150kW ultra-rapid charger can draw as much power as a small supermarket or an entire block of flats. Trying to install several of these on a site with a weak connection is like trying to fill a swimming pool through a drinking straw—the infrastructure just can't handle the flow.

This power deficit is a widespread problem. While the UK's expansion of charge points has been impressive on paper, it has also created a stark geographical divide.

The Reality of Grid Upgrades

When your site’s power supply falls short, the traditional path is to request a grid upgrade. This means getting in touch with your regional Distribution Network Operator (DNO) , the company that manages the local electricity network.

Be warned: the process is often slow, painfully complex and shockingly expensive. Here’s a taste of what it usually involves:

- Initial Application and Survey: The DNO comes out to assess your site's current connection and check the capacity of the nearest substation.

- Cost Quotation: You get a quote for the upgrade work. This can be anything from tens of thousands to well over a million pounds.

- Long Lead Times: Even if you can swallow the cost, the physical work of laying new cables and installing new substations can take 12-18 months and sometimes even longer.

These hurdles contribute to a patchy, inconsistent network. The number of rapid and ultra-rapid chargers in the UK did grow by a healthy 33% in the past year, reaching over 15,000 units . But the coverage is still all over the place. Areas like rural Scotland and Cornwall often get left behind and reliability remains a headache, with only 20% of faulty chargers fixed within 24 hours. You can read more about the challenges facing the UK's EV charging rollout.

Mitigating the Immediate Impact

For any business staring down a constrained grid, the prospect of a huge bill and a year-long wait can feel like a dead end. But it doesn't have to be. There are foundational strategies you can use to manage the immediate impact on your existing connection while you plan a more robust, long-term solution.

One of the most effective first steps is to implement load management . This is a smart technology that dynamically balances the power being sent to your EV chargers. For instance, if two cars plug into a dual-outlet station, the system can dial down the power to each vehicle to make sure you don't exceed your site’s overall power limit and trip the breakers.

While load management is a useful safety net, it’s not the whole answer. It often means cars charge much more slowly than advertised, which is a sure-fire way to frustrate drivers. Think of it as a helpful first step but one that doesn't solve the fundamental problem of not having enough power. This is what sets the stage for more advanced solutions that can truly unlock your site's rapid charging potential.

Solving Grid Problems with Battery Storage and Renewables

Hitting a wall with a constrained grid connection doesn't mean you have to give up on your rapid EV charging plans. While the costs and delays of a DNO upgrade can feel like a dead end, there’s a powerful alternative that neatly sidesteps the entire problem. It’s a solution that not only plugs the power gap but also transforms your site into a sophisticated, self-sufficient energy asset.

The game-changer here is the Battery Energy Storage System (BESS) . Think of it as a large, intelligent power reservoir for your site, acting as the perfect buffer between a weak grid and the heavy demands of a rapid EV charger.

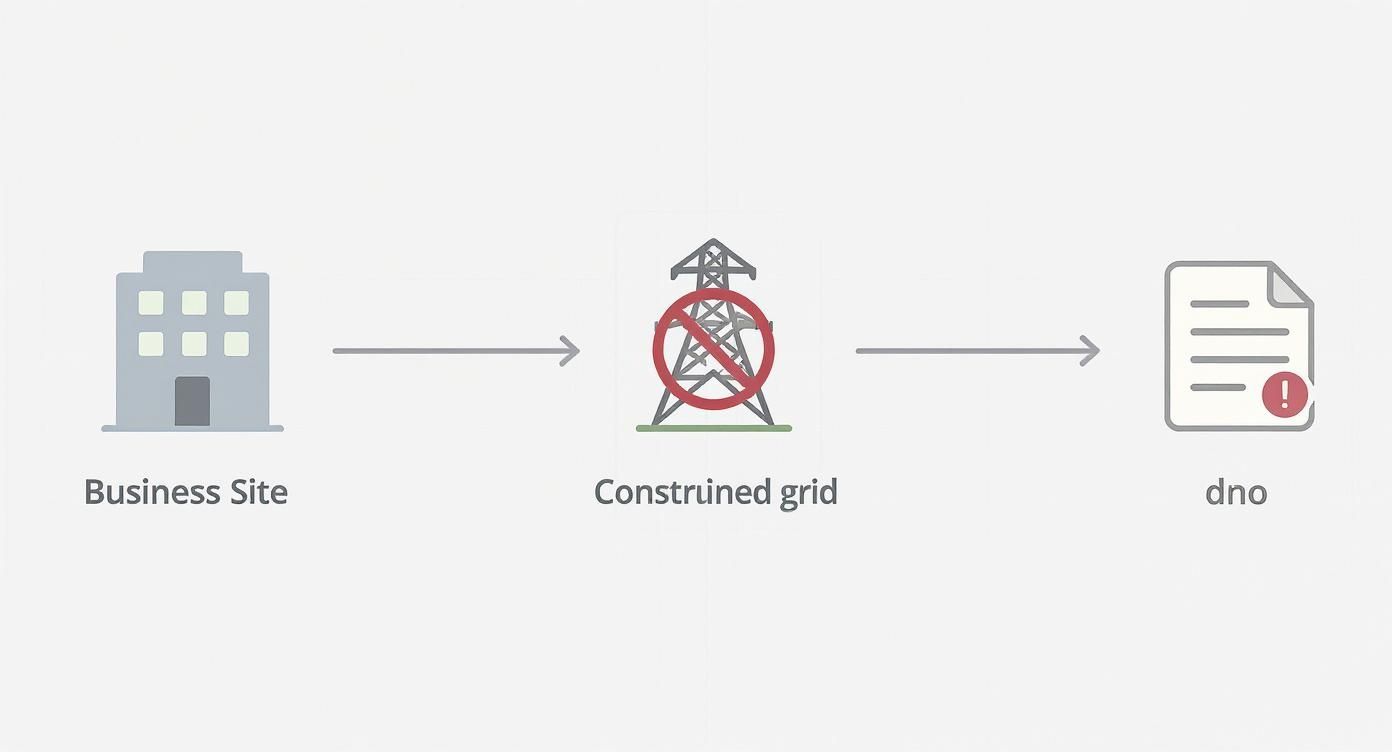

This is the typical journey for a business hitting grid constraints—from the initial ambition to the reality check from the DNO.

The diagram shows a familiar story: a business wants high-power infrastructure, only to be stopped in its tracks by the local grid’s limitations during the DNO application process.

How Battery Storage Unlocks Rapid Charging

A BESS gets around the grid problem with elegant simplicity. Instead of trying to pull a massive surge of power from the grid the moment an EV plugs in, the battery system does the hard work in advance. It can slowly 'trickle charge' itself over many hours—even from a very weak grid connection—often overnight when electricity is cheapest.

When a driver arrives needing a quick top-up, the BESS unleashes all that stored energy in a powerful, controlled burst straight to the EV charger. The grid itself is barely touched. This means you can deliver 150kW or even 350kW charging from a grid connection that might only be able to supply 30kW .

This technology completely decouples the charging speed you offer from the capacity of your grid connection. It makes rapid EV charging possible for almost any commercial site, no matter its existing electrical setup.

This approach brings a whole host of benefits beyond just enabling fast charging. For businesses staring down the barrel of a daunting grid upgrade quote, a BESS is often a far more cost-effective and significantly faster way to get a rapid charging hub up and running. To get the full picture, you can explore our deeper dive into how battery energy storage systems solve UK grid issues for EV charging.

Creating a Self-Sufficient Energy Ecosystem

The true potential of a BESS is unlocked when you pair it with on-site renewables, like solar PV panels on your building’s roof or a car park canopy. This combination creates a genuinely independent and resilient distributed energy ecosystem.

During sunny periods, your solar panels generate clean, free electricity. Instead of exporting it to the grid for pennies, you can store this energy directly in your BESS. This stored solar power can then be used later to charge EVs, dramatically slashing your reliance on the grid and your electricity bills.

This integrated system gives you several key advantages:

- Reduced Energy Costs: You generate and store your own power, minimising your exposure to volatile grid prices.

- Enhanced Green Credentials: Offering charging powered by on-site renewables is a powerful statement, showing a real commitment to sustainability.

- Energy Security: Your charging station can keep running even during local power outages, providing a reliable service that customers and fleets can count on.

From Cost Centre to Profit Centre with Energy Arbitrage

A BESS does more than just power your chargers; it turns your site into an active player in the wider energy market. This opens up clever revenue streams like energy arbitrage , a principle that's simple but incredibly effective.

Your intelligent BESS constantly monitors wholesale electricity prices as they fluctuate throughout the day. It automatically charges itself from the grid when energy is cheap and plentiful—typically overnight.

Then, during peak hours when demand and prices are high, your system can do one of two things. It can either use that cheap, stored energy to power your site and EV chargers (avoiding peak tariffs) or it can sell the stored energy back to the grid for a tidy profit. This smart trading turns your charging installation from an operational cost into a dynamic, revenue-generating asset.

Building Your Business Case for Rapid Charging

So, you're convinced by the technology. The next logical step is figuring out if installing a rapid charger actually makes financial sense. A successful project isn’t just about the hardware; it’s built on a solid business case that carefully weighs the initial investment against the long-term returns.

This means you need to look well beyond the sticker price of the charger itself and build a complete, honest picture of its profitability over time.

Understanding the Total Cost of Ownership

The first piece of the puzzle is calculating the Total Cost of Ownership (TCO) . This is a far more insightful metric than the purchase price alone because it captures every single expense you'll encounter over the asset's entire life. A realistic TCO analysis gives you a clear-eyed view of the total investment required before you can even think about profits.

To build an accurate financial model, you have to account for all the associated costs. These usually fall into a few key areas:

- Hardware Costs: This is the obvious one – the price of the rapid EV charger and any battery energy storage systems (BESS) you need.

- Installation Expenses: Don't underestimate this. Groundwork, cabling and commissioning can vary massively depending on how complex your site is.

- Grid Connection Fees: If your site needs a grid upgrade, the costs quoted by the Distribution Network Operator (DNO) can be eye-watering.

- Ongoing Maintenance: Think service contracts, software subscriptions and potential repair bills. These are vital for keeping your charger online and reliable.

- Energy Costs: The price you pay for electricity is a major ongoing operational cost that directly impacts your bottom line.

A comprehensive TCO model prevents nasty surprises down the line. Factoring in every cost from day one is the foundation for calculating a reliable Return on Investment and securing project funding.

Modelling Your Revenue Streams

Once you've got a handle on the costs, it's time to model your potential revenue. A rapid charger for electric cars can generate income in several ways, both directly and indirectly. And the market is certainly there for the taking. The UK’s charging infrastructure is growing at an unprecedented rate, with over 17,356 rapid or ultra-rapid chargers now online. This expanding network proves there's a clear and growing appetite for public charging.

Direct revenue is straightforward: you charge drivers a fee for the electricity they use. By setting a price per kilowatt-hour (kWh), you create a simple income stream every time someone plugs in. This model is easy to manage and offers predictable returns based on how much the charger is used.

But don't overlook the indirect benefits, which can be just as valuable, particularly if you run a retail or hospitality business. A rapid charger acts as a powerful magnet for EV drivers, increasing customer footfall and the amount of time they spend on-site. Think about it: a driver waiting 20-30 minutes for their car to charge is very likely to pop into your shop, café or restaurant.

For logistics firms, the "revenue" comes from a different angle: improved operational efficiency. Reduced charging downtime means your electric fleet stays on the road, making deliveries and earning money. We explore some of these models in our guide on how to earn significant revenue from rapid EV chargers.

Analysing Your Return on Investment

Finally, you bring the cost and revenue models together to analyse the Return on Investment (ROI) . The ultimate question is simple: how long will it take for the charger to pay for itself and start generating a net profit?

Your ROI timeline will be shaped by a few critical factors. Charger utilisation rates are paramount – a charger that's constantly in use will obviously generate revenue much faster. Fluctuating energy prices also play a huge role, affecting both your running costs and the price you can competitively charge your customers.

By modelling different scenarios—what if utilisation is low, medium or high?—you can project a realistic ROI timeframe. This robust analysis gives you the hard data needed to build a compelling business case and demonstrate the clear financial logic behind investing in a rapid charging hub.

Right, you've seen the potential of rapid EV charging. Now, how do you turn that vision into a real, revenue-generating asset on the ground?

It’s about having a clear, structured plan. This isn't something you rush into. We can break down the journey of deploying a rapid charging hub into three manageable phases, guiding you from a simple idea to a fully operational site.

Let’s walk through the steps to get you there with confidence.

Phase 1: The Scoping and Feasibility Groundwork

Every successful project starts with a solid foundation. Before you even think about ordering hardware, you need to do your homework on the site and get crystal clear on your goals.

-

Site Assessment: First things first, get to know your location inside and out. How much space do you realistically have? What’s the state of your existing electrical setup? Is there potential to add solar panels on the roof to offset costs down the line? These physical characteristics will define what’s possible.

-

Grid Connection Enquiry: This is arguably the most critical step. You need to put in an early, informal enquiry to your Distribution Network Operator (DNO). Finding out your grid capacity upfront will tell you everything. It reveals whether you’re facing a constrained grid connection, which will fundamentally shape your entire technology strategy. Don't skip this.

-

Define Your Use Case: What are you actually trying to achieve here? Are you aiming to pull in retail customers passing by, serve a dedicated private fleet of commercial vans or build a major public charging destination? Your core objective dictates the type and number of chargers you’ll need.

Phase 2: System Design and Making the Numbers Work

With that initial data in hand, you can move from ideas to a concrete plan. This is where you design the system and build a business case that stands up to scrutiny.

This stage is about more than just picking a charger. It’s about designing an integrated energy system where the EV charging, battery storage and potential renewables work together to maximise efficiency and profitability from distributed energy.

Here’s what this phase involves:

- Technology Selection: Now you can choose the right mix of rapid EV chargers . Crucially, this is also when you’ll specify the capacity needed for your Battery Energy Storage System (BESS) , especially if that DNO enquiry revealed any grid limitations.

- Financial Modelling: It’s time to build a detailed financial forecast. This needs to cover the total cost of ownership, your projected revenue from charging fees and any potential extra income you could make from grid services or energy arbitrage.

- Securing Funding: With a solid business case showing a strong return on investment, you’re in a great position to approach lenders or apply for grants. That financial model is your key to unlocking capital.

Phase 3: Installation and Going Live

This is the final leg, where your project comes to life. It demands sharp project management and close collaboration with expert partners to ensure everything is installed correctly, safely and to all regulatory standards.

Partnering with specialists who understand the interplay between grid-scale batteries, mobile EV charging and fixed infrastructure is non-negotiable.

They’ll handle the physical installation, manage the final sign-off with the DNO and commission the entire system. Every component gets tested and proven ready for public use. Once that’s done, you can launch your charging hub and start capitalising on the EV transition.

Your Questions Answered

When you start digging into the world of commercial rapid EV charging, a lot of practical questions naturally come up. Here are some of the most common queries we get from businesses and fleet managers weighing up an investment in their own rapid charging setup.

How Much Space Do I Actually Need for a Rapid Charger?

It’s definitely more than just the charger itself. A typical setup for a 150kW DC rapid charger, along with its separate power cabinet and an integrated Battery Energy Storage System (BESS), will usually take up the space of two or three standard parking bays .

The BESS unit alone can be anything from the size of a large cabinet to a small shipping container, depending on how much energy you need it to hold. It's also crucial to plan for enough room around the kit for safety clearances, cable trenching and future maintenance access. A proper site survey is always the first and most important step.

Can I Install Rapid Chargers if My Site Has a Weak Grid Connection?

Yes, absolutely. This is precisely where combining EV charging with battery storage becomes a real game-changer. For any site with a constrained grid connection, a BESS is the perfect workaround.

The system can quietly ‘trickle charge’ itself from the weak grid over many hours, usually overnight when local demand is low. It can also pull power from on-site renewables like solar panels. When a vehicle plugs in, the BESS discharges all that stored energy at a high rate directly to the charger, completely bypassing the grid's limitations. This makes rapid charging possible in places where it would otherwise be a non-starter without hugely expensive grid upgrades.

What’s Involved in Ongoing Maintenance?

For any commercial charging operation, reliability is everything. Ongoing maintenance for a rapid charger setup is pretty straightforward and typically includes:

- Annual physical inspections of all the hardware, connections and cabling to check for wear and tear and ensure everything is safe.

- Regular software updates to keep the system compatible with new vehicle models and payment platforms.

- Periodic testing of all safety features and the emergency stop functions.

When you have grid-scale batteries in the mix, this also involves monitoring the health and performance of the BESS. A solid service agreement that includes remote monitoring is the best way to guarantee maximum uptime and protect your revenue streams.

How Long Does the Whole Installation Process Take?

The timeline really depends on two things: the complexity of your site and how long it takes to work with the Distribution Network Operator (DNO) on the grid connection. A relatively simple, straightforward installation might take between three to six months from the first conversation to switching it on.

However, if a major grid upgrade is needed, you’re then working to the DNO’s schedule, which can easily stretch the project out to 12-18 months or even longer. This is another huge reason why battery-backed solutions are so popular—they often sidestep the need for grid upgrades, meaning they can be deployed much, much faster.

At ZPN Energy , we specialise in deploying battery-backed rapid charging solutions that bypass grid constraints and accelerate your journey to electrification. Our unique, UK-manufactured systems are designed for reliability, efficiency and profitability. Discover how we can power your business at https://www.zpnenergy.com.