Electric Vehicle Fleet Charging Infrastructure: Key Insights

Switching to an electric fleet is about more than just buying new vehicles. You need to build a solid electric vehicle fleet charging infrastructure to support them. Think of it as the energy ecosystem for your entire operation—it’s what keeps your vehicles on the road, your costs in check and your business ready for whatever comes next.

Building Your Fleet's Charging Foundation

The journey to an all-electric fleet does not start with a charger; it starts with a plan. Creating a detailed blueprint before a single cable is laid is the most important thing you can do. It is the difference between a smooth transition and a series of expensive, frustrating mistakes.

This initial planning stage is all about getting to grips with your unique situation. It involves a deep dive into three core areas: your physical site, how your fleet actually operates day-to-day and the long-term financial picture. Nail this from the start and you will sidestep the logistical nightmares and budget blowouts that can derail an otherwise great project.

Performing a Realistic Site Assessment

First things first: take a hard look at your depot or operational hub. A proper site assessment is not just about finding a spare corner to stick some chargers. You need to evaluate your current electrical capacity, figure out what groundworks might be needed for cabling and plan charger placement to keep traffic flowing smoothly.

It is common for businesses to find out their current grid connection just cannot handle the demands of large-scale EV charging. Discovering this early is crucial because getting a grid upgrade from a Distribution Network Operator (DNO) can be a very long and expensive process.

Analysing Fleet Duty Cycles and Energy Needs

Next up, you need to become an expert on how your vehicles work. Understanding your fleet's duty cycles—the daily rhythm of mileage, usage and downtime—is absolutely essential for designing a charging strategy that actually works in the real world.

You will need answers to a few key questions:

- Dwell Time: How long are your vehicles parked up and available to charge, like overnight at the depot?

- Energy Consumption: What is the average daily energy use (in kWh) for the different types of vehicles you run?

- Turnaround Speed: Do some vehicles need a quick top-up mid-shift or is overnight charging enough for everyone?

The answers will tell you exactly what kind and how many chargers you need. A fleet of delivery vans that come back to base every night has completely different charging needs from a fleet of electric buses that require rapid top-ups between routes.

An effective charging plan is built on data. By mapping out energy demand against vehicle availability, you can create a staggered charging schedule that minimises strain on the grid and reduces costly peak demand charges.

Calculating the Total Cost of Ownership

Finally, you have to look beyond the sticker price of the chargers. The total cost of ownership (TCO) gives you the real financial picture by factoring in all the costs over the system's entire life. This includes installation, any grid upgrades, ongoing maintenance, software fees and of course the electricity itself. Forgetting these can lead to some nasty surprises down the road and you can learn more about the true cost of poor charging infrastructure in our detailed guide.

As you lay the groundwork for your charging needs, it pays to think bigger. Integrate this planning with your wider operational strategies, including the latest Top Fleet Management Best Practices. By taking this holistic view, you will build a foundation that is not just powerful and reliable but financially sustainable for the long haul.

Choosing the Right Charging Technology

Picking the right charging hardware is one of the most important calls you will make. It directly shapes your fleet's efficiency and whether your vehicles are ready to roll when you need them. This is not about just buying the fastest chargers on the market; it is about creating a smart, blended ecosystem that fits the daily reality of your vehicles' routes and schedules.

Get this mix right and you will keep your vehicles on the road whilst keeping a firm grip on your energy bills. The goal is to build a versatile electric vehicle fleet charging infrastructure that serves every vehicle without wasting money on power you do not need.

The Workhorses: AC Chargers for Overnight Dwell Time

For most fleets running a return-to-base model—think last-mile delivery vans that come home every night—Alternating Current (AC) chargers are the backbone of the operation. Often called Level 2 chargers, these units are the dependable workhorses of depot charging.

AC chargers deliver power outputs from 7kW to 22kW . They are not going to win any speed records but their strength lies in their steady performance over long periods. A van parked for eight to ten hours overnight can easily go from empty to a full charge, making it a reliable and cost-effective way to get ready for the next day's shift.

This approach brings two huge benefits:

- Lower upfront cost: The hardware for AC charging is significantly cheaper to buy and install than high-power DC systems.

- Reduced grid strain: Their lower power draw is much kinder to your site’s electrical supply. This makes it easier to manage your total energy load and can often help you avoid expensive grid upgrades.

The Sprinters: DC Rapid and Ultra-Rapid Charging

But what about when time is money and you cannot afford to wait? That is when Direct Current (DC) rapid chargers step in. These powerful systems are the sprinters of the charging world. They bypass the vehicle's onboard converter and push electricity straight into the battery, slashing charge times.

DC rapid ev charging stations usually start at 50kW and can climb well beyond 350kW for the ultra-rapid models. A standard 50kW unit can add about 100 miles of range in just 30-40 minutes, which is a game-changer for high-use vehicles like electric buses or trucks that need to get back on the road ASAP.

Think of your charging strategy like a transport network. AC chargers are the local roads, reliably getting vehicles where they need to go overnight. DC rapid chargers are the motorways—built for high-speed, direct journeys when time is critical. A successful fleet uses both to keep everything flowing smoothly.

The Flexible Response: Mobile EV Charging

So what happens if a vehicle runs out of juice far from a depot or you need power somewhere you do not have fixed chargers? This is where mobile ev charging comes to the rescue. These units are essentially big batteries on wheels, ready to deliver a quick DC charge to a stranded vehicle or provide temporary power at a remote site.

Mobile chargers give you incredible flexibility. They can be a perfect stopgap whilst you are waiting for permanent infrastructure to be installed or a dedicated resource for off-site jobs. They can turn a costly recovery situation into a minor hiccup and keep your fleet moving, no matter what the day throws at you.

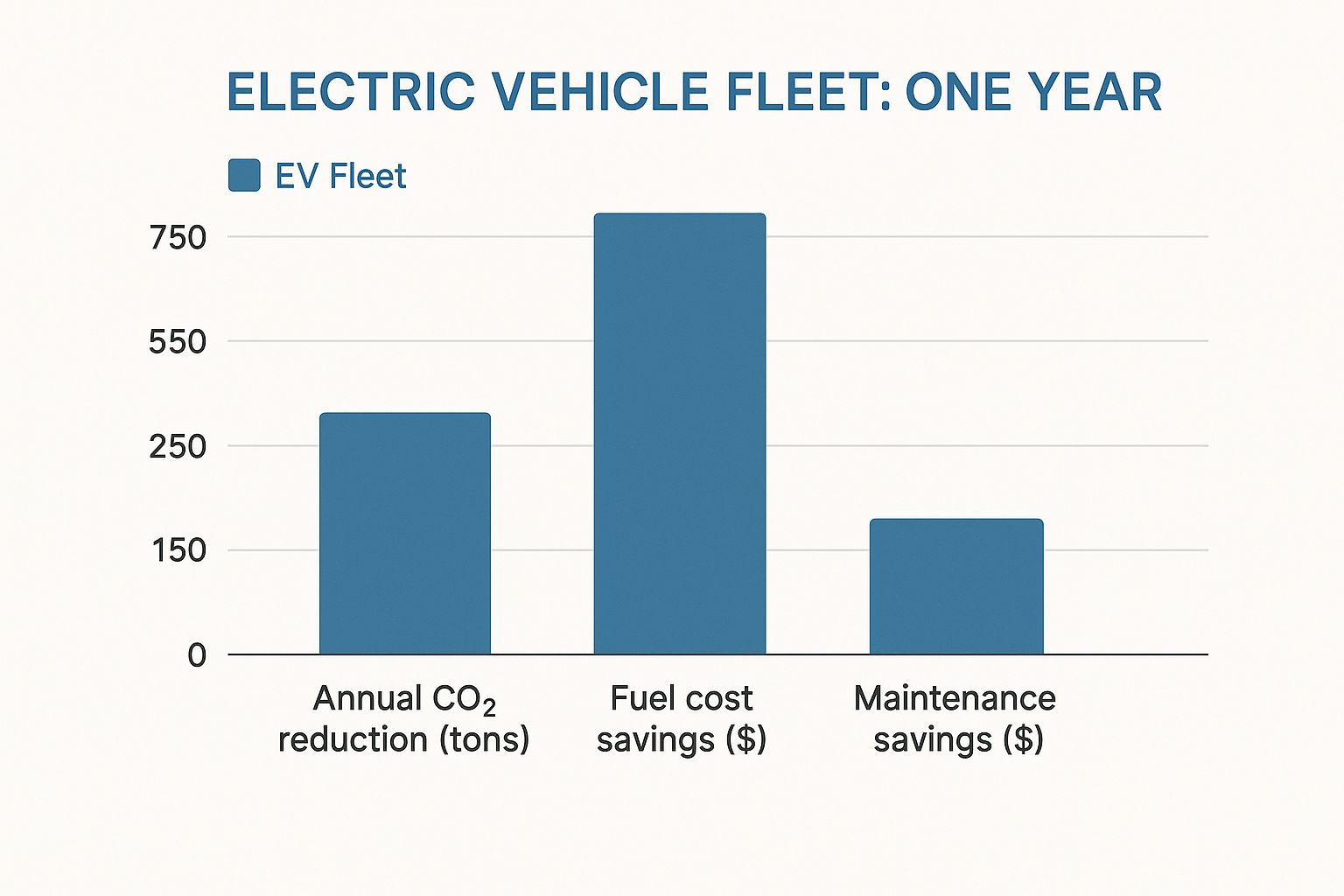

As you plan your infrastructure, it helps to keep the end goal in mind. The infographic below shows the very real financial and environmental wins a well-planned electric fleet can deliver in just one year.

To help you visualise how these technologies stack up, we have put together a quick comparison.

Comparing Fleet Charging Technologies

| Charging Type | Power Output | Typical Charge Time (Fleet Vehicle) | Best Use Case |

|---|---|---|---|

| AC (Level 2) | 7kW – 22kW | 6-12 hours | Overnight depot charging for return-to-base vehicles (e.g., delivery vans) |

| DC Rapid | 50kW – 150kW | 30-90 minutes | Quick top-ups during shifts for high-utilisation vehicles (e.g., buses) |

| DC Ultra-Rapid | 150kW – 350kW+ | 15-45 minutes | "Splash and dash" charging for heavy-duty trucks or time-critical routes |

| Mobile DC | 20kW – 60kW | Variable | Emergency roadside assistance or temporary power at remote sites |

The numbers do not lie. The savings on fuel and maintenance alone often provide a powerful return on your infrastructure investment. By layering these different charging options—the steady AC workhorses, the speedy DC sprinters and the flexible mobile units—you design a resilient, cost-effective system that truly powers your fleet for the future.

Tackling the Grid Connection Challenge

One of the biggest hurdles in rolling out your electric vehicle fleet charging infrastructure often has nothing to do with the chargers or the vehicles themselves. It is the local power grid. Most commercial sites simply were not built to handle the enormous electrical demand of a depot full of rapid EV chargers. This grid constraint is a critical bottleneck that can stop a project dead in its tracks if you do not plan for it from day one.

Ignoring your site's power limits is a recipe for disaster, plain and simple. It can lead to eye-watering budget overruns and project delays that stretch on for months or even years. Figuring out how to navigate this challenge is not just a technicality; it is the foundation of a successful and timely fleet electrification project.

Understanding Your Site's Power Capacity

Before you even think about installing a single charger, you need a clear answer to a fundamental question: how much power can your site actually draw? This is where your Distribution Network Operator (DNO) comes into the picture. The DNO is the company managing the electricity network in your area and they hold the keys to any grid upgrades you might need.

Your first move should be to request a grid capacity assessment. This process will tell you your site's Maximum Import Capacity (MIC) – the total amount of power you are allowed to pull from the grid at any one time. This number is the hard ceiling for your entire operation, including every last kilowatt your new EV chargers will demand.

Think of your grid connection like a water pipe feeding your building. No matter how many high-powered taps (your chargers) you install, you cannot get more water than the main pipe can deliver. A grid assessment tells you the exact size of that pipe.

The Reality of Grid Upgrades

If the assessment shows your current connection cannot handle the load – a very common discovery for depots planning rapid ev charging – you will need a grid upgrade. This means the DNO has to install new, heavier-duty infrastructure, like bigger cables or perhaps even a brand-new local substation, just to boost your power supply.

Be warned, though: this is rarely a quick or cheap fix. The process is often long and complex, involving:

- Detailed Surveys: Engineers must assess the local network and meticulously plan the new connection.

- Logistical Hurdles: This can involve securing planning permissions and even arranging road closures for the necessary civil works.

- Significant Costs: The bill for major upgrades can easily run into hundreds of thousands of pounds.

- Long Lead Times: It is not unusual for complex grid reinforcement projects to take 12-24 months to complete from start to finish.

This lengthy timeline is frequently the single biggest cause of delays in fleet electrification projects. A business that buys its vehicles and chargers without getting grid capacity sorted first can find its shiny, expensive new assets sitting idle for over a year.

Bypassing Grid Constraints with Smart Solutions

Thankfully, waiting for a grid upgrade is not your only option. Modern energy technology means you can build a powerful charging hub even when dealing with ev charging from constrained grid connections . The solution lies in generating, storing and managing power intelligently on-site, which dramatically reduces how much you need to lean on the DNO.

This is where the idea of distributed energy really comes into its own. Instead of just pulling power from the grid, you create your own local energy ecosystem. This is typically done by combining on site renewables like solar panels with grid scale batteries , often called a Battery Energy Storage System (BESS). You can explore various strategies for grid energy management to see how these systems build resilience and deliver huge cost savings.

These systems cleverly 'trickle charge' the on-site batteries from the grid during cheap, off-peak hours or from your solar panels during the day. That stored energy is then unleashed to power your rapid chargers whenever your fleet needs it. This approach effectively sidesteps the grid bottleneck, letting you deploy high-power charging infrastructure without a costly and time-consuming grid upgrade. It puts you back in control of your energy future.

Achieving Energy Independence with Batteries and Solar

Relying solely on the grid to power your electric fleet is a risky game. You are left exposed to two huge threats: grid capacity limits and wildly unpredictable energy prices.

For many businesses, the local network simply cannot deliver the punch needed for rapid charging. On top of that, peak-time electricity costs can quickly cancel out the savings you thought you would make by going electric. The real solution? Create your own resilient energy ecosystem and break free from grid dependency.

This strategy hangs on the powerful partnership of on site renewables and grid scale batteries , often called a Battery Energy Storage System (BESS). When you generate and store your own electricity, you take back control. It is a move that dramatically cuts costs and ensures your fleet is always ready to roll, no matter what is happening on the national grid.

The Power of On-Site Solar Generation

The most direct route to generating your own clean electricity is with solar panels, installed right on your depot rooftops or on adjacent land. A commercial solar setup can pump out a serious amount of power during daylight hours, feeding directly into your depot's energy needs.

But there is an obvious catch. The sun does not always shine when your vehicles need charging the most. The bulk of depot charging happens overnight when solar generation is at zero. This mismatch between when you make power and when you need it is precisely where energy storage becomes the hero of the story. It is the critical link that makes renewables truly work for fleet operations.

Unlocking Energy with Battery Storage Systems

Think of a BESS as a large, intelligent energy reservoir for your depot. It neatly solves the timing problem of renewables by capturing and banking all that solar energy generated throughout the day.

This stored power can then be unleashed hours later to charge your vehicles overnight. You are effectively time-shifting free, clean solar energy to exactly when you need it.

A Battery Energy Storage System does more than just store solar power. It can also draw cheap electricity from the grid during off-peak night-time hours, when tariffs are at their lowest. This stored energy is then used to avoid drawing expensive power during peak daytime periods, a strategy known as 'peak shaving'.

This dual function—storing both solar and cheap grid power—makes ev charging and batteries a formidable combination. It provides a reliable buffer against grid outages and price spikes, creating a stable, low-cost energy supply for your entire operation. For businesses looking to tap into this powerful synergy, understanding the full benefits of commercial solar and battery storage is the first step toward genuine energy independence.

Building a Distributed Energy Ecosystem

When you combine ev charging from constrained grid connections with on-site solar and battery storage, you are creating your own micro-grid—a form of distributed energy . Instead of just being a passive consumer, your depot transforms into an active, intelligent energy hub. This approach delivers some game-changing advantages.

-

Bypassing Grid Upgrades: A BESS can deliver the intense power needed for rapid ev charging without forcing you into a costly and painfully slow grid upgrade from the DNO. The battery handles the short, sharp bursts of demand, whilst your existing grid connection simply has to 'trickle charge' the battery over many hours.

-

Protecting Against Volatility: By using your own stored energy, you insulate your business from the chaos of fluctuating electricity prices. This makes budgeting for energy costs predictable and stable.

-

Reducing Carbon Footprint: Powering your fleet with sunshine from your own roof drastically cuts your carbon emissions, bolstering your company's sustainability credentials and helping you hit environmental targets.

-

Creating New Revenue Streams: It does not stop there. Advanced systems can even sell stored energy back to the grid when it is most needed, creating an entirely new income stream for your business.

This integrated approach turns your electric vehicle fleet charging infrastructure from a simple operational cost into a strategic asset. It puts you firmly in control of your energy destiny, delivering resilience, cost savings and a significant competitive edge.

Unlocking the Power of Distributed Energy

Today’s electric vehicle fleet charging infrastructure is so much more than just a row of plugs. It is quickly becoming a smart, interconnected ecosystem where your vehicles, chargers, on-site batteries and even solar panels all work in harmony. This is the world of Distributed Energy Resources (DERs) and it is what turns your depot from a simple energy drain into a dynamic energy hub.

When you start thinking this way, you move beyond just refuelling vehicles. You begin to actively manage, store and deploy energy to squeeze out every drop of efficiency, slash your running costs and build genuine operational resilience. It is a fundamental shift but it is crucial for future-proofing your entire fleet operation.

The Brain of the Operation: The Charge Management System

At the heart of any modern distributed energy setup is a sophisticated software platform known as a Charge Management System (CMS). Think of it as the air traffic controller for your depot's power. It keeps an eye on everything in real-time: which vehicles are plugged in, how charged they are, the current price of grid electricity and what your solar panels are generating.

With this complete picture, the CMS makes smart decisions every single second. It can fast-track charging for vehicles that need to leave first thing, hold back charging for others until cheaper off-peak rates kick in or funnel surplus solar power into your grid scale batteries to use later.

A Charge Management System orchestrates the complex dance between your energy supply and your fleet's demands. Its goal is simple: make sure every vehicle is ready for its shift using the cheapest, greenest and most reliable electricity available.

This automated control is what stops you from accidentally overloading your grid connection and getting hit with eye-watering peak demand charges. It is the essential 'brain' that unlocks the full financial and operational power of all your hardware.

Integrating Renewables and Battery Storage

The real magic of a DER approach happens when you pair ev charging and batteries with on site renewables like solar panels. Suddenly, your depot’s roof becomes a mini power station, generating clean, free electricity all day long. A Battery Energy Storage System (BESS) then acts as your personal energy reservoir, storing that solar power or cheap overnight grid electricity.

This creates a powerful, self-sufficient loop:

- Generate: Your solar panels produce zero-carbon electricity when the sun is out.

- Store: The BESS captures any excess energy and saves it for when you need it most.

- Deploy: That stored energy is then used to charge your fleet overnight, shielding you entirely from expensive peak grid prices.

This level of on-site control is becoming a serious strategic advantage. As of January 2025, the UK had already surpassed 51,000 public EV charging points, with 12% of those being rapid chargers. This explosive growth, detailed in reports from the Department for Transport, puts more and more strain on the national grid, making on-site generation a smart move for any forward-thinking fleet operator.

The Future: Vehicle-to-Grid Technology

Looking ahead, things are set to get even smarter with Vehicle-to-Grid (V2G) technology. V2G allows your electric vehicles not only to draw power from the grid but also to push energy from their batteries back to the grid.

Imagine this: when your vehicles are parked up for the night, their batteries can work together as one giant, distributed power plant. Your CMS could automatically sell power back to the grid during peak evening hours when electricity is most expensive, creating a brand new revenue stream for your business.

But it is not just about the money. By providing this service, your fleet can actively help balance and stabilise the national grid, supporting the UK’s wider transition to renewable energy. It transforms your vehicles from simple operational assets into key players in the national energy landscape.

Common Questions About Fleet Charging Infrastructure

As you get closer to electrifying your fleet, it is natural for a lot of questions to pop up. Let's face it, building out a robust electric vehicle fleet charging infrastructure is a major project and you need clear answers to make confident decisions.

This final section tackles the most common queries we hear from fleet managers like you. We will give you straight answers on everything from costs and technology to the day-to-day practicalities, helping you tie up the loose ends in your planning.

What Is the Biggest Hidden Cost in Setting Up Fleet Charging?

Hands down, the single biggest and most frequently overlooked cost is the grid connection upgrade. It is easy to focus on the price of the chargers themselves but the real shock to the system often comes from the work needed to get enough power to your site in the first place.

If your depot’s current electrical supply cannot handle the new demand, the upgrade work from the Distribution Network Operator (DNO) can be eye-wateringly expensive and take an incredibly long time. It is not unusual for these projects to run into six figures and take well over a year to complete.

Here’s the most important piece of advice we can give: get a grid capacity assessment done right at the very start. It will tell you exactly what power you have to play with and what an upgrade might involve, saving you from huge, costly surprises down the road.

Can I Mix Different Types of Chargers in My Depot?

Yes and honestly, you probably should. For most commercial fleets, a blended strategy using different charging technologies is the smartest and most cost-effective way to operate. A one-size-fits-all approach rarely works in the real world.

The idea is to use a mix of charging speeds that directly match what your vehicles are doing all day.

- AC Chargers (7-22kW): These are perfect for vehicles that sit idle for long periods, like delivery vans that park up overnight. They’re much cheaper to install and put less strain on your site’s overall power limit.

- DC Rapid Chargers (50kW+): Save these for your workhorse vehicles that cannot afford to be off the road for long. Think electric buses or trucks running back-to-back shifts that need a quick top-up to get back out there.

By combining the two, you can make your hardware budget go further and manage your site's total power draw far more effectively. It stops you from splashing out on expensive rapid chargers that your fleet does not actually need.

How Does a Battery Energy Storage System Save Money?

Think of a Battery Energy Storage System (BESS) as a financial shock absorber for your energy costs. It is a clever bit of kit that shields you from the volatile energy market and it saves your electric vehicle fleet charging infrastructure money in three key ways.

First, it lets you play the energy market. A BESS can charge up on cheap, off-peak electricity overnight or soak up free energy from your solar panels during the day. You then use that stored energy to charge your vehicles when grid prices are at their highest, which directly slashes your electricity bills.

Second, a BESS helps you dodge punishing 'demand charges'. These are fees based on your single highest spike of energy use. By using stored battery power to "shave the peak," it smooths out your demand from the grid, lowering that charge and saving you a fortune.

Finally, it can help you delay or even completely avoid a hugely expensive grid upgrade. A BESS can deliver the high power needed for rapid ev charging without you needing a bigger connection from the street, saving you a massive upfront capital cost.

Is Mobile EV Charging a Viable Long-Term Solution?

Whilst mobile ev charging is a brilliant tool to have in your arsenal, it is not really a long-term solution for your main depot charging. Its true value lies in its flexibility and its role as a backup, not as the core of your daily operations.

It is best to think of mobile chargers as a specialist resource. They are perfect for roadside emergencies to get a stranded vehicle moving again or for providing temporary power at a site where you have no fixed chargers. They can also be a fantastic stopgap to keep your fleet running whilst you are waiting for permanent infrastructure to be installed.

But for routine, day-in-day-out charging at your depot, fixed chargers tied into a smart management platform will always be cheaper and more efficient. And speaking of keeping things running, fleet safety is just as crucial as infrastructure. For specific advice on fire safety for EVs, have a read of your guide to an electric vehicle fire extinguisher to make sure you have got all your bases covered.