Industrial Energy Monitoring Systems A Practical Guide

Think of an industrial energy monitoring system as the command centre for your facility's power. It is the tool that gives you a magnifying glass over every watt being used, providing granular, real-time data on every corner of your operation. In an era of volatile costs, integrating renewables and managing power-hungry assets like rapid EV charging, this kind of system is not just a nice-to-have but a strategic necessity.

Your Facility's Command Centre for Energy Intelligence

Imagine trying to navigate a complex journey with no map and a blacked-out dashboard. That is what running an industrial site without a robust energy monitoring system feels like. This is far more than a simple smart meter; a true industrial energy monitoring system (IEMS) is a sophisticated network of hardware and software working together.

Its job is to deliver precise, real-time intelligence on every kilowatt-hour your facility draws. With energy costs climbing, decarbonisation targets looming and complex new loads coming online, that visibility is indispensable. The modern industrial site is no longer a passive energy consumer but a dynamic player on the grid.

Managing a New Energy Era

The demands on industrial energy infrastructure have grown almost overnight. Facilities now have to juggle a complex mix of assets, all of which need smart, coordinated management. An effective IEMS is what gives you the control to orchestrate these different elements so they work in harmony, not against each other.

Here are a few key areas where this oversight becomes absolutely critical:

- EV Charging: You need to manage the intense, often unpredictable power demands from rapid EV charging and mobile EV charging fleets, especially when you are working with a constrained grid connection.

- Grid-Scale Batteries: An IEMS lets you perfect the charge and discharge cycles of your on-site batteries, so you can store cheap off-peak energy for later or even sell power back to the grid when prices are high.

- Combined On-Site Renewables: It is all about maximising the self-consumption of the energy you generate from solar or wind and seamlessly blending it with other power sources.

- Distributed Energy: This is how you create a resilient microgrid, balancing your EV charging, batteries and various energy resources to guarantee operational continuity while keeping costs down.

The growth in this space speaks for itself. In the UK, the market for energy management systems was valued at around USD 2.9 billion and is on track to nearly double, hitting USD 5.6 billion by 2030 . Industrial systems like these make up the largest chunk of that market for a good reason.

An industrial energy monitoring system transforms raw data into strategic intelligence. It empowers you to not only see your energy consumption but to actively control it, turning what was once a fixed overhead into a manageable and even profitable asset.

By giving you a crystal-clear view of consumption patterns, these systems pave the way for proactive, intelligent decisions. The data you gather is the foundation for building a resilient, efficient energy hub that is ready for whatever the future throws at it. For a deeper dive, you can explore our guide on the role of AI and big data in revolutionising energy management. This foundational intelligence is what allows you to cut waste, integrate renewables and manage high-demand assets without breaking a sweat.

Deconstructing Your Energy Monitoring System

To really get the most out of an industrial energy monitoring system, you need to understand what makes it tick. Do not think of it as a single piece of kit; it is more like a complete ecosystem where hardware and software work together. This combination gives you the detailed oversight needed to run a modern industrial site with all its complex energy demands.

Each piece has a specific job, turning raw electrical data into intelligence you can actually use. The system captures precise information from high-demand assets—think rapid EV charging stations or grid-scale batteries—and makes sense of it all. It shows you exactly where your energy is going, what is causing those unexpected demand peaks and how to fine-tune performance across your entire operation.

The Hardware: The Eyes and Ears on Your Grid

The foundation of any solid energy monitoring system is the hardware that gathers the raw data. These are the physical devices installed throughout your facility, measuring consumption at every critical point, from the main incomer right down to individual circuits or machines. Without accurate hardware, everything else is just guesswork.

Key hardware components usually include:

- Sub-Meters: These are fitted to specific circuits to isolate and measure the power used by individual high-load assets. They are essential for figuring out the precise energy draw of a bank of rapid EV chargers or a large battery storage system.

- Sensors: It is not just about electricity. Sensors can also monitor environmental factors like temperature, pressure and flow. This data adds crucial context, helping you see how surrounding conditions affect the performance of your distributed energy resources.

- Data Loggers and Gateways: Think of these as the central nervous system for your hardware. They collect all the data from your sub-meters and sensors, bundle it up and securely send it over to the software platform for analysis.

For a truly complete picture, an energy monitoring system often relies on advanced mechanisms; understanding broader IT infrastructure monitoring tools can provide useful context for the technology that underpins it all. This hardware creates a robust data collection network, making sure the information feeding the software is both accurate and timely.

The Software: The Brain of the Operation

If the hardware provides the raw data, the software is what translates it into something meaningful. This is the brain of your industrial energy monitoring system. It is where information is collected, processed and presented through easy-to-use dashboards and reports. This is where you will spot the patterns, flag anomalies and uncover opportunities to get more efficient.

A modern IEMS platform does not just show you data; it tells you a story. It highlights where your EV charging hub is most stressed, when your on-site renewables are most productive and how your battery storage can best support a constrained grid connection.

The software is what empowers you to shift from just watching your energy use to actively managing it. To give you a clearer idea, the table below breaks down how each component works together to create a complete system.

A Breakdown of IEMS Components and Their Functions

Here is a look at the essential parts of an industrial energy monitoring system and the role each one plays.

| Component | Primary Function | Typical Application | Data Provided |

|---|---|---|---|

| Sub-Meters | Measure electricity usage on specific circuits or for individual assets. | Monitoring a bank of rapid EV chargers or a single production line. | Kilowatt-hours ( kWh ), voltage, current, power factor. |

| Environmental Sensors | Track conditions like temperature, humidity or pressure. | Optimising HVAC performance or monitoring battery operating temperatures. | Temperature ( °C ), relative humidity ( % ), pressure ( PSI ). |

| Data Gateway | Collects and transmits data securely from hardware to the cloud. | Centralising data from dozens of sensors across a large facility. | Raw data packets, device status, connectivity logs. |

| Cloud Platform/Software | Analyses data, generates alerts and provides user dashboards. | Visualising EV charging demand against on-site solar generation. | Real-time dashboards, historical trends, custom reports, alerts. |

Ultimately, it is the seamless integration of these hardware and software components that delivers the powerful insights needed to take control of your industrial energy consumption.

Strategic Gains Beyond Reducing Your Energy Bills

While cutting energy bills is often the first thing people think of, the real strategic value of an industrial energy monitoring system lies in building long-term operational resilience. It is about future-proofing your facility against a constantly changing energy landscape. This is where an IEMS stops being just a cost-saving tool and becomes an essential asset for managing complex, high-demand operations.

The system's true power shines when you are dealing with the intense demands of modern industrial assets. Picture a logistics hub deploying a fleet of electric vehicles. The massive, sudden power draw from rapid EV charging could easily overwhelm a constrained grid connection, leading to crippling penalties or even shutting down operations entirely.

An IEMS acts as an air traffic controller for your energy and intelligently manages these intense loads. It ensures charging cycles are optimised to prevent demand spikes, making it possible to run a large EV fleet without the need for expensive and time-consuming grid upgrades.

Orchestrating On-Site Energy Resources

This level of control is not just for EVs; it extends to all your distributed energy resources. An IEMS lets you perfectly orchestrate how on-site renewables like solar panels work together with large-scale battery storage. Without proper monitoring, these assets often operate in isolation, never quite delivering their full potential.

With a fully integrated system, you can start using some seriously sophisticated strategies:

- Maximise Self-Consumption: Store excess solar energy generated during the day in your batteries and then use it to power your night shift or your EV charging hub.

- Grid Services Participation: Automatically sell that stored energy back to the grid when wholesale prices are high, creating an entirely new revenue stream for your facility.

- Peak Shaving: Use battery power during peak demand periods to avoid the highest tariff rates—a tactic that offers a rapid return on your investment.

This capability transforms your facility from a passive energy consumer into an active, intelligent player in the energy market. It is a critical step in developing a resilient and profitable energy strategy. Our guide to battery energy storage systems in the UK explores how these technologies are powering a greener future.

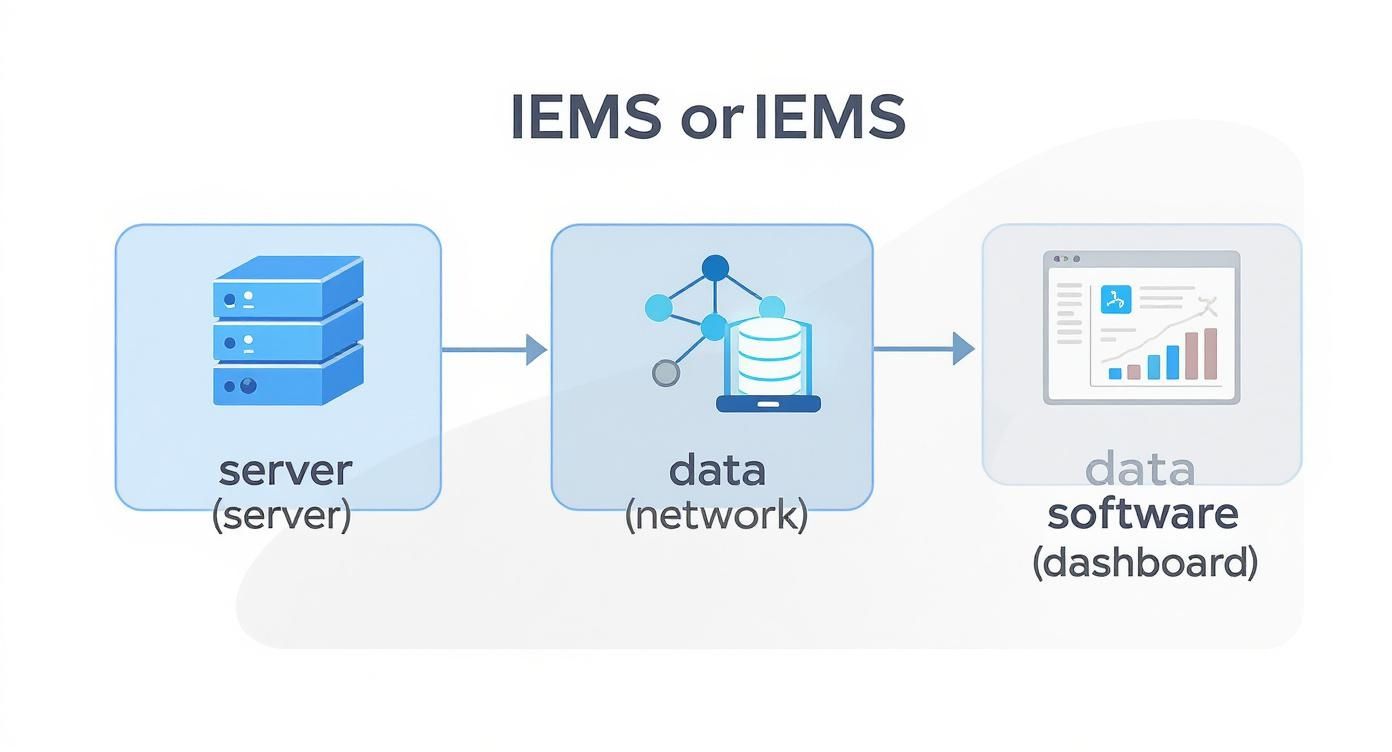

The infographic below shows how an IEMS turns raw data from hardware into clear, software-driven insights.

As you can see, the hardware on the ground captures the energy data, which is then processed by the software and served up as actionable intelligence on a dashboard.

Unlocking Predictive Maintenance and Compliance

Beyond orchestrating your energy, the granular data from an IEMS gives you powerful insights into the health of your equipment. By constantly monitoring the energy signatures of critical machinery, the system can spot subtle anomalies that signal an impending failure. A motor drawing just a little more current than usual could be an early warning of bearing wear, letting you schedule maintenance long before a catastrophic breakdown occurs. This move from reactive repairs to predictive maintenance can slash equipment failures by up to 14% .

An industrial energy monitoring system provides the hard data needed to justify future investments. It replaces guesswork with a clear business case, showing exactly how new technologies like mobile EV charging or on-site solar will perform and what their return will be.

What is more, this detailed data is invaluable for compliance. For organisations aiming for standards like ISO 50001 , an IEMS provides the verifiable, continuous data logging required to achieve and maintain certification. This does not just bolster your environmental credentials; it opens doors to new business with partners who prioritise sustainability.

The momentum here is undeniable. The UK industrial power monitoring system market is growing steadily, pushed by national decarbonisation goals and strict energy reporting regulations. Projections show the market expanding at a compound annual growth rate of around 6.8% between 2025 and 2035 , reflecting the UK's focused drive towards net zero in the industrial sector. This growth highlights just how valuable these systems are in creating resilient, compliant and profitable industrial operations.

A Practical Roadmap for Implementing Your System

Moving from theory to action requires a clear plan. Installing an industrial energy monitoring system is not about flipping a switch; it is a structured process that, when done right, delivers maximum impact from day one. Think of it as methodically building a foundation of data-driven intelligence that is fine-tuned to your site's specific challenges.

The journey starts by understanding your current energy landscape in minute detail. This first phase sets the stage for every decision that follows, ensuring your investment is aimed at the areas where it will yield the biggest returns. Without this solid baseline, you are just guessing where the inefficiencies are hiding.

Starting With a Detailed Energy Audit

Before you even think about installing a sensor, you need to carry out a comprehensive energy audit. This is like creating a detailed map of your facility's energy consumption. The goal is to pinpoint your biggest energy hogs and establish a clear benchmark to measure all future improvements against.

This audit needs to dig deeper than just surface-level utility bills. It means identifying high-demand assets like banks of rapid EV chargers, large-scale battery systems or energy-hungry production lines. By understanding where your energy is really going, you can prioritise your monitoring efforts far more effectively.

A thorough energy audit does not just show you how much energy you use; it reveals the 'when' and 'why' behind your consumption. This context is critical for managing complex loads like mobile EV charging from a constrained grid connection.

The information gathered here is the bedrock of your implementation strategy. It highlights the problem areas and gives you the hard evidence needed to build a strong business case for the project, making it much easier to get buy-in from key stakeholders.

Selecting the Right Hardware and Software

With a clear picture of your energy landscape, the next step is to choose the right tools for the job. Not all industrial energy monitoring systems are created equal. Your choice has to be guided by the unique challenges uncovered in your audit, whether that is managing a weak grid connection or integrating a new solar array.

The key is to match the technology to your real-world operational needs. You should be asking questions like:

- Hardware Precision: Do you need sub-meters that can capture the volatile, high-power draws of rapid EV charging or are general circuit-level monitors enough?

- Software Analytics: Does the platform offer specific tools for managing distributed energy resources, like optimising battery storage to work alongside on-site renewables?

- Scalability: Will the system grow with your business? Make sure it can handle future assets, like an expanded EV fleet or more battery capacity.

Choosing a system designed for industrial complexity ensures you get actionable insights, not just a flood of raw data. This is where you can see how ZPN Energy’s business energy management system drives revenue , not just cost savings.

Phased Rollout and Proving ROI

A "big bang" implementation can be disruptive and expensive. A much smarter approach is a phased rollout, kicking off with a pilot project focused on a single high-impact area. This lets you demonstrate value quickly and builds momentum for a full facility-wide deployment.

For example, you could start by monitoring just one bank of EV chargers or a notoriously inefficient production line. This focused approach provides a clear, measurable test case. Once you have shown tangible savings or operational improvements, getting the green light for the next phase becomes a whole lot simpler.

To track your success, you must set meaningful Key Performance Indicators (KPIs) right from the start. These should be tied directly to your business goals, such as:

- Reducing Peak Demand Charges: Measure the drop in peak load from the grid, especially during high-tariff periods.

- Increasing Renewable Self-Consumption: Track the percentage of on-site solar energy used directly by your facility versus being exported.

- Improving Asset Uptime: Monitor equipment for signs of stress, linking energy data to lower maintenance costs and fewer breakdowns.

By setting and tracking these KPIs, you can build a powerful, data-backed case that shows a clear and compelling return on investment. This is how an energy monitoring system transforms from a perceived cost into a proven strategic asset.

Real-World Scenarios in UK Industrial Settings

So, how does an industrial energy monitoring system actually perform in the wild? To get a proper feel for it, let us look at three common scenarios playing out across UK industry right now. Each one starts with a familiar challenge and ends with a data-led solution, showing the real impact on costs, carbon and uptime.

These examples are not just about saving a bit of electricity. They dive into the complexities of modern energy, where facilities are juggling the intense power demands of EV charging, blending renewables with battery storage and using hard data to hit tough compliance targets.

Logistics Depot Managing Rapid EV Charging

Picture a large UK logistics depot making the jump to an electric fleet. The plan was simple: install a hub of rapid EV chargers . The problem? Their grid connection was already stretched thin. Trying to power multiple rapid chargers at once was a recipe for crippling demand charges or, worse, tripping the mains for the entire site.

They were faced with a classic dilemma: how do you charge dozens of vans efficiently without paying for a hugely expensive and slow grid upgrade? The answer was to pair an advanced industrial energy monitoring system with on-site battery storage. The system became the traffic controller for electricity across the whole depot.

- Load Balancing: First, the system kept a constant eye on the site's total energy use. It then intelligently allocated power to the EV chargers, making sure the grid connection was never pushed past its limit.

- Peak Shaving: During the night, when electricity is cheap, the system would fill up the on-site battery. This stored energy was then deployed during the day to help power the rapid chargers, avoiding the need to draw expensive peak-rate electricity from the grid.

- Mobile EV Charging Integration: The system even managed the charging schedules for several mobile EV charging units , ensuring these flexible power packs were fully charged and ready to go without adding to the peak load.

The outcome was a fully operational rapid charging hub running smoothly on the existing grid connection. This smart approach saved them hundreds of thousands of pounds in upgrade costs and slashed their peak energy charges by over 40% . All while guaranteeing the electric fleet was charged and ready to roll every morning.

Manufacturing Site with Solar and Grid-Scale Batteries

Over in the Midlands, a medium-sized manufacturer wanted to tackle its carbon footprint and high energy bills by fitting a large solar PV array on its factory roof. But there was a snag. Their production lines were busiest outside of peak sunshine hours, meaning a lot of that free, green energy was going to waste.

Their goal was to use as much of their own solar power as possible and maybe even turn their roof into a source of revenue. So, they combined their on-site renewables by connecting their solar panels to a grid-scale battery , with an IEMS acting as the central brain for the whole operation.

By combining on-site renewables with battery storage and intelligent monitoring, an industrial facility can transform from a passive energy consumer into an active, profitable participant in the national grid.

The system’s software was constantly crunching numbers—production schedules, weather forecasts and live energy market prices—to make smart, automated decisions. It would funnel surplus solar energy into the battery instead of exporting it to the grid for pennies. Then, when grid prices shot up in the early evening, the system would discharge the battery to either power the factory or sell the electricity back to the grid for a healthy profit. Just like that, their energy system went from being a major cost to a new revenue stream.

Cold Storage Facility and Compliance Targets

Finally, let us look at a cold storage facility. They were under serious pressure to cut their energy use to meet both internal sustainability targets and tightening government regulations. Their refrigeration units were the obvious culprits, guzzling the most power, but they had no idea which specific units were the least efficient or on the verge of failing.

The fix was to install sub-meters on every major refrigeration circuit, all feeding data back into their industrial energy monitoring system . This granular view gave them a detailed, unit-by-unit breakdown of energy consumption. It did not take long for the system’s analytics to find the problem: two older refrigeration units were drawing far more power than the newer, identical models.

Armed with this data, they had a clear business case to replace the inefficient equipment. The upgrade resulted in a 15% reduction in the site's total energy consumption, allowing them to comfortably meet their compliance goals. Better yet, the new equipment paid for itself in just under 18 months and the continuous monitoring now serves as an early warning system for any future maintenance headaches.

The Future of Industrial Energy Intelligence

Industrial energy monitoring systems are moving far beyond just being diagnostic tools. We are seeing them evolve into predictive, strategic assets that do not just report on energy use but actively and automatically fine-tune it. The next wave is all about integrating artificial intelligence and machine learning.

Imagine a system that can look at production schedules, weather forecasts and real-time grid prices to make decisions on its own. It might pre-cool a facility just before a heatwave hits or schedule a fleet of EVs to charge when energy is cheapest and greenest. This is the difference between reacting to your energy bill and proactively optimising your entire operation.

Becoming an Active Player on the Grid

This leap in intelligence is turning industrial sites into active players in the national energy market, largely through concepts like Virtual Power Plants (VPPs) . A VPP is not a single, physical power station; it is a network of smaller, decentralised assets like your on-site batteries, solar panels and EV charging hubs all working together.

Instead of having these resources operate in isolation, an intelligent energy monitoring system can bundle them up. Your facility can then act as a single, coordinated unit, selling services back to the grid. Suddenly, your site is not just a consumer of energy but is also earning revenue by helping to balance supply and demand, which is absolutely vital as the grid relies more on intermittent renewables.

An industrial energy monitoring system is no longer just a tool for saving money on bills. It is a strategic asset that enables your facility to generate revenue and support national decarbonisation by becoming a flexible, intelligent hub in a decentralised energy future.

This kind of data-led approach is made possible by the wide adoption of smart metering technology. To give you a sense of scale, by the end of Q2 2025, Great Britain is set to have nearly 40 million smart and advanced meters installed in homes and small businesses, which is about 69% of all meters. You can discover more insights about this national rollout and see how it is paving the way for smarter energy management everywhere.

The Critical Need for Cybersecurity

As these systems get smarter and more connected, securing them becomes a top priority. Let us be clear: an internet-connected system that controls grid-scale batteries or large EV charging networks is a potential target for cyber threats. Recent research has already flagged vulnerabilities in some energy management software, revealing hundreds of unpatched systems accessible online.

Robust cybersecurity is not an optional extra; it is a fundamental requirement. This means keeping systems patched, restricting direct online exposure and implementing strong security protocols. Protecting these intelligent networks is crucial for maintaining operational integrity and safety. The future of industrial energy intelligence depends on building systems that are not only smart and profitable but also secure and resilient.

Frequently Asked Questions

Bringing new technology into your facility always raises a few questions. We have put together some straightforward answers to the most common queries we hear about industrial energy monitoring, especially for sites managing complex assets like EV charging hubs and distributed energy resources.

How Much Can Our Facility Realistically Save?

It is the big question and the answer is significant. Most facilities see savings between 8% to 25% . The exact figure really comes down to your industry, your starting point with energy efficiency and—most importantly—how you use the data you get.

Facilities with high-demand equipment, like rapid EV charging stations or large-scale refrigeration, often see the fastest and most impressive returns. By pinpointing and fixing inefficiencies in these power-hungry areas, the savings can be substantial right from the get-go.

Can This System Be Retrofitted Into an Older Facility?

Absolutely. One of the best things about modern monitoring technology is its flexibility. Thanks to wireless sensors and modular designs, we can install a comprehensive industrial energy monitoring system right into your existing infrastructure.

This means you can avoid the huge disruption and cost of a complete rewire. It allows older facilities to get the same detailed energy intelligence as a new build, helping you modernise your operations and effectively manage assets like mobile EV chargers or on-site batteries.

The payback period for an investment in an industrial energy monitoring system can be surprisingly fast, often under two years. For facilities with high energy costs—or those using advanced strategies like peak load shedding for EV charging—the return on investment can arrive in a matter of months.

By adopting this technology, older sites can compete on efficiency and cost with even the newest operations.

Take control of your facility's energy consumption and unlock new revenue streams. ZPN Energy offers fully integrated industrial energy monitoring systems designed to manage everything from rapid EV charging to grid-scale batteries. Discover our solutions at https://www.zpnenergy.com.