UK Guide to Inverters for Motors: Powering the Future of Energy

At its core, an inverter for a motor is a smart device that takes direct current (DC) and transforms it into alternating current (AC). This conversion is the key to precisely controlling an electric motor's speed and torque, a must-have for boosting energy efficiency in everything from industrial machinery to the latest distributed energy systems.

The Inverter's Role in a Modern UK Energy Grid

In the UK's fast-changing energy landscape, you can think of a motor inverter as an intelligent translator for electricity. It is no longer just a simple component buried in a machine but a central piece of the puzzle enabling our shift towards a more flexible, decentralised power network.

As we integrate more on-site renewables like solar panels and deploy large, grid-scale batteries, the need for precise control is more critical than ever. Inverters deliver the sophisticated management needed to keep power flow stable and ensure the grid remains reliable even with a diverse mix of energy sources coming online.

This technology is the heart of what is known as a Variable Frequency Drive (VFD) . The VFD is the complete package—rectifier, DC bus and the inverter itself—that gives us that finely tuned control over a motor's behaviour.

Unlocking New Energy Capabilities

This level of control is fundamental to tackling some of the UK’s biggest energy challenges. Take the nationwide push for electric vehicles. Inverters are what make it all work, managing the power flow in everything from a home EV charger to a massive rapid-charging hub. They are crucial for balancing the load on the grid, especially where local connections are already stretched thin.

Inverters also play a starring role in Battery Energy Storage Systems (BESS) . By managing the two-way flow of energy, they allow batteries to soak up excess power from renewables and feed it back to the grid when demand spikes. This is vital for maintaining grid stability and getting the most value out of our clean energy assets.

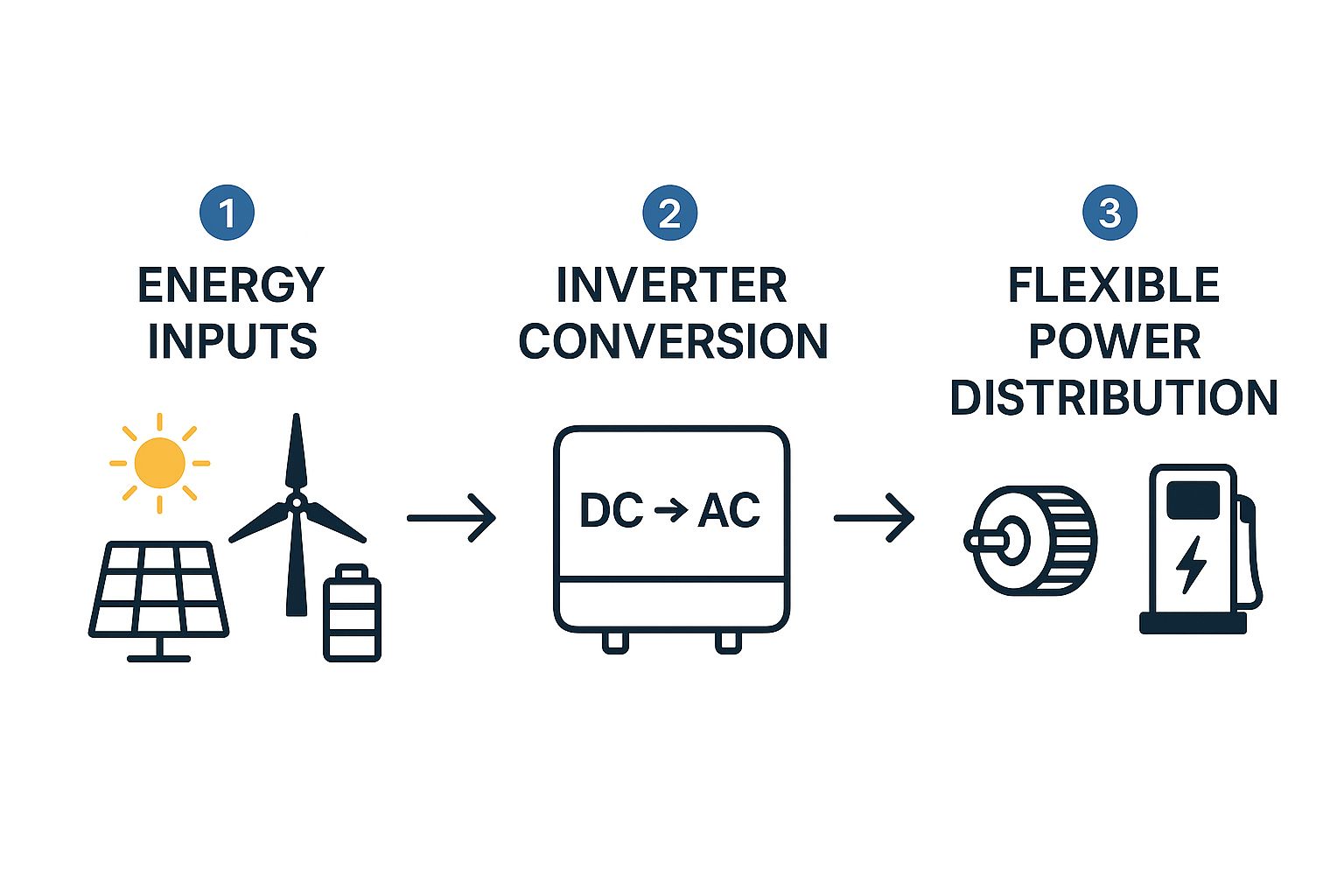

This diagram shows just how central the inverter is to modern energy systems, acting as the crucial link between various power sources and their end use.

Whether the electricity is coming from wind, solar or a battery, the inverter is what converts and directs that power to run motors and EV chargers as efficiently as possible.

The Foundation of a Smarter Grid

Ultimately, the inverter’s job goes far beyond simple power conversion. It is an essential building block for a smarter, more resilient national grid. By enabling precise control over distributed energy resources, it supports:

- Rapid EV Charging: Allowing high-power charging without overwhelming local electrical infrastructure, even from constrained grid connections.

- Mobile EV Charging: Providing the flexibility to get power to wherever it is needed most.

- Grid Stability: Helping to balance supply and demand by managing energy from grid-scale batteries and on-site renewables.

- Distributed Energy: Supporting the shift away from a few massive power stations to a network of smaller, local energy sources.

To get a fuller picture of how complex energy infrastructure comes together, it is useful to look at related technologies. For instance, exploring LVDT applications in energy systems shows how other specialised sensors and devices contribute to overall performance and reliability. It is this kind of technology that makes the modern, flexible grid a reality.

How a Motor Inverter Actually Works

To really get why an inverter is so important for motors, we need to pop the lid and see what is going on inside. At its heart, the device is a master energy shaper. It takes one form of electricity and sculpts it into another with incredible precision, unlocking huge gains in efficiency and control for everything from rapid EV charging to grid-scale batteries.

Think of it like having a set of super-fast taps controlling water flow. If you could open and close these taps thousands of times per second in just the right sequence, you could create a perfectly smooth, continuous wave. A motor inverter does something very similar with electricity, using ultra-fast electronic switches to shape a DC supply into a clean AC output.

The complete system that does this is known as a Variable Frequency Drive (VFD) and it works in three distinct stages. Each step is vital for turning raw power into a finely controlled energy source.

The Three Stages of Power Conversion

The magic of a VFD lies in its three core stages, which work together to transform a standard electrical supply into a precisely managed output for the motor. It is this internal process that allows for exact adjustments to motor speed and torque, ensuring the AC waveform is perfectly tailored to the job at hand.

| Stage | What It Does | Simple Analogy |

|---|---|---|

| 1. The Rectifier | Converts incoming AC power from the grid into DC power. | It is like a one-way gate for electricity, letting the power flow in but not back out, creating a stable foundation. |

| 2. The DC Bus | Stores and smooths the DC power, removing any fluctuations or 'ripples'. | Think of it as a reservoir or a buffer tank, holding a steady supply of energy ready for the next step. |

| 3. The Inverter | Takes the smooth DC power and chops it up into a synthetic AC waveform using a technique called Pulse Width Modulation (PWM) . | This is the sculpting stage, where the steady DC stream is carefully pulsed to create a brand new, adjustable AC wave. |

By managing the frequency of this new AC waveform, a VFD can control a motor's speed with incredible accuracy. This three-stage process is fundamental to how modern distributed energy systems operate, allowing a rapid EV charger to deliver power safely or a grid-scale battery to feed electricity back to the grid that perfectly matches its requirements.

By precisely controlling the frequency and voltage supplied to a motor, an inverter avoids the energy waste associated with running motors at a fixed, full speed. This control is the cornerstone of energy efficiency in modern renewable and distributed energy applications.

Inverter Technology in the UK Energy Sector

This ability to control motors so precisely has made the inverter a lynchpin of the UK’s energy sector. It is not just about convenience but a critical tool for hitting national energy efficiency targets and integrating renewables.

Demand for these systems is growing fast. The global inverter duty motor market is projected to jump from USD 5.3 billion in 2025 to USD 16.6 billion by 2035 , and the UK is a major driver of this growth. Our focus on combining on-site renewables with EV charging and battery storage is pushing widespread adoption.

UK businesses are using inverter-driven systems to cut running costs, meet tough environmental regulations and reduce mechanical wear and tear on their equipment. This trend is only getting stronger with the move towards a smarter, more distributed energy network. You can learn more about these market trends over on Future Market Insights.

When you understand what is happening inside a VFD, it becomes clear why this technology is so important. It provides the intelligent control needed to bridge the gap between raw power sources and the sophisticated demands of a modern, efficient energy system.

Solving EV Charging Challenges with Inverter Technology

Inverter technology is proving to be the key to unlocking one of the UK’s biggest energy hurdles: the widespread adoption of electric vehicles. At its heart, an inverter for motors and charging systems is the smart bit of kit that manages the flow of power, turning the idea of rapid EV charging from constrained grid connections into a practical reality. It is this ability to intelligently convert and control electricity that makes all the difference.

This is a massive deal, especially when you look at the UK’s existing electrical infrastructure. Many places, particularly rural spots or older city centres, have grid connections that just cannot handle the huge power draw needed for several rapid EV chargers running at once. It is a major roadblock to expanding the national EV network but it is a challenge that inverter technology combined with battery storage is built to overcome.

Overcoming Grid Limitations with Smart Technology

When you pair an inverter with a battery, it acts like a sophisticated energy buffer. This setup creates a local energy reserve that can be filled up during off-peak hours when electricity is cheaper and there is less demand on the grid. The inverter manages this whole process, converting AC grid power into DC to be stored in the battery.

Then, when drivers need to charge during peak times, the system simply reverses the flow. The inverter taps into the stored DC energy from the battery, converts it back into precisely controlled AC power and delivers it to the vehicle at top speed. The best part? This all happens without putting a sudden, heavy strain on the local grid connection.

This 'store and release' method effectively decouples the charging speed from the grid's immediate capacity. It allows for the installation of 150kW rapid chargers on a connection that might otherwise only support a fraction of that power, making widespread rapid EV charging economically and technically feasible.

This approach is not just a clever workaround but a much smarter way of managing distributed energy. It turns a potential grid headache into a flexible asset. You can find more detail on how these systems stabilise energy supply by exploring the benefits of battery-backed EV charging.

Enabling Mobile and Flexible Charging Solutions

The very same technology is behind the growing field of mobile EV charging. A battery and inverter system can be mounted on a vehicle or built into a portable unit, creating a charging station that can be rolled out wherever it is needed. This is perfect for all sorts of scenarios:

- Fleet Operations: Charging vehicles at depots without having to pay for expensive grid upgrades.

- Roadside Assistance: Giving stranded EV drivers an emergency top-up.

- Events and Remote Locations: Setting up temporary charging facilities where no permanent infrastructure exists.

In every case, the inverter is the crucial piece of the puzzle, safely converting stored battery power into a usable form for any EV. This flexibility is vital for building confidence in the EV transition, making sure power is available not just at fixed points but wherever and whenever demand pops up. To get a real sense of what it takes to implement these solutions, this expert guide to EV charger installation offers some fantastic insights into the practical requirements.

By acting as the intelligent heart of both static and mobile EV charging systems, the inverter is making the UK's move to electric transport possible. It smooths out demand, strengthens the weak points in our grid and delivers the adaptability we need for a future of electric mobility.

Powering a Resilient Grid with Batteries and Renewables

At this scale, powerful bidirectional inverters become the central technology inside a Battery Energy Storage System (BESS). These devices are masters of two-way energy flow. They handle both the charging of batteries from renewable sources and the discharging of that power back into the grid when it is needed most. This capability is fundamental to building a more flexible and decarbonised UK energy grid.

The Inverter as a Grid Traffic Controller

Think of a bidirectional inverter in a BESS as an intelligent traffic controller for the grid. When solar panels are generating more electricity than the grid needs, the inverter directs this surplus energy into the batteries, converting it from AC to DC for storage.

Conversely, when demand spikes or the sun stops shining, the inverter instantly reverses its function. It draws the stored DC power from the batteries, converts it back into grid-compliant AC and releases it precisely where it is needed. This seamless, rapid response is what helps to maintain the stability of the entire system.

By managing this two-way flow, inverter-led battery systems provide critical grid-balancing services. They act as a shock absorber, smoothing out the intermittent nature of renewables and ensuring a reliable, constant supply of power around the clock.

This function is vital for the UK's energy security. By storing clean energy when it is abundant and releasing it during peak demand, these systems reduce our reliance on fossil fuel power stations that would otherwise need to be fired up to meet short-term demand. For a deeper look into this area, our guide explains the details behind UK energy storage solutions.

Delivering Essential Grid Services

The role of an inverter within a BESS goes far beyond simple energy storage. It actively participates in maintaining grid health by delivering a range of essential services. These are what keep the lights on and prevent blackouts, especially as more variable renewable sources are added to the grid.

Key services provided by inverter-led systems include:

- Frequency Regulation: The grid must be maintained at a very precise frequency ( 50 Hz in the UK). Inverters can inject or absorb power in milliseconds to correct tiny deviations, keeping the grid stable.

- Peak Shaving: During periods of high demand, such as cold winter evenings, these systems discharge power to reduce the strain on the grid. This avoids the need for expensive and polluting 'peaker' plants.

- Renewable Energy Integration: They make renewables practical by storing excess energy that would otherwise be wasted—a process known as curtailment.

This growing reliance on renewables is driving significant investment in related technologies. The UK solar inverter market, valued at approximately USD 860 million in one recent year, is projected to reach USD 1,550 million by 2035 . This growth is a direct result of government policies aimed at reducing carbon emissions and promoting sustainable energy solutions, highlighting the crucial role of efficient power conversion equipment. You can explore the full research on the UK solar inverter market and its drivers.

Ultimately, the inverter is the enabling technology that allows grid-scale batteries and on-site renewables to work together as a cohesive, stabilising force for the national grid. It is the intelligence that turns distributed energy assets into active, valuable participants in our modern energy network.

Choosing the Right Inverter for Your Project

Picking the right inverter for your project in the UK is not just about theory. It is about matching the real-world demands of your system with the right technical specs. Whether you are building a rapid EV charging hub, a grid-scale Battery Energy Storage System (BESS) or a mobile EV charging solution, getting the inverter right is fundamental to success, safety and long-term performance.

Get this decision wrong and you could be looking at poor efficiency, equipment failing long before its time or even falling foul of UK grid standards. It is vital to move past a surface-level understanding and really dig into the specific criteria that make an inverter suitable for your exact application. Things like power ratings, voltage compatibility, control methods and environmental protection are just the starting point.

These technical details are what determine how an inverter will actually behave under load and in its specific operating environment. Making a smart choice begins with a clear-headed assessment of your project's unique needs from day one.

Defining Your Core Requirements

Before you even glance at a datasheet, you need to clearly define what you need the inverter to do. An inverter destined for a mobile EV charging unit has a completely different set of requirements from one integrated into a grid-scale battery system combined with on-site renewables. The first step is always to establish your non-negotiable technical and operational parameters.

Start by asking these fundamental questions:

- What is the maximum power (kW) the motor or system will ever need? Always build in a sensible margin for peak loads.

- What are the input and output voltage requirements? This has to line up perfectly with both your power source—be it the grid, a battery or solar panels—and the end application.

- What level of control precision is necessary? A simple industrial motor might only need basic speed control but a BESS needs highly sophisticated frequency regulation to support the grid.

Answering these questions gives you a solid foundation. It helps you immediately filter out unsuitable options and narrow your focus to inverters that are genuinely fit for purpose.

Critical Specifications for UK Applications

Once your basic needs are clear, it is time to evaluate the specific features and compliance standards that are crucial for any UK-based project. This is where you need to look beyond the initial purchase price and consider the total cost of ownership. A cheaper unit that is inefficient or non-compliant will cost you far more in the long run through wasted energy and potential fines.

The UK's dynamic distributed energy market is a major driver for this technology. To give you some perspective, the UK photovoltaic (PV) inverter market alone generated around USD 412.3 million in revenue recently and is forecast to more than double to USD 840.9 million by 2030 . This growth is fuelled by national renewable energy policies and the falling cost of solar, highlighting just how important it is to select high-quality, compliant inverters. The fact that central PV inverters—used in large-scale projects—make up the biggest slice of this market shows the sheer scale of investment in UK renewable infrastructure. You can get a closer look at these trends by exploring detailed findings on the UK PV inverter market.

An inverter’s efficiency rating is one of the most important figures to consider. A rating of 98% versus 95% might seem like a small difference but over a 10-year operational lifespan, this 3% improvement translates into significant energy and cost savings.

Thinking about the details is key, especially when comparing different applications. This checklist below helps frame the decision-making process for two common scenarios: a rapid EV charging station versus a BESS installation.

Inverter Selection Checklist for UK Applications

| Selection Criterion | EV Charging Considerations | BESS Considerations |

|---|---|---|

| Power Rating | Must handle high, intermittent loads for rapid charging (e.g., 50kW to 350kW ), often from a constrained grid connection. | Needs to support sustained high power for grid export and import, matched to battery capacity. |

| Bidirectionality | Typically unidirectional (grid-to-vehicle), unless V2G (Vehicle-to-Grid) is a requirement. | Essential. Must efficiently manage both charging from the grid/renewables and discharging to the grid. |

| Grid Compliance | Must meet UK standards for connection, including harmonics and power factor. | Must comply with stringent grid codes (e.g., G99) for providing ancillary services like frequency response. |

| IP Rating | Often requires a high IP rating (e.g., IP65 ) for outdoor, public-facing installations. | Can sometimes be lower if installed inside a protected, climate-controlled container. |

By systematically working through points like these, you can build a clear technical profile of the ideal inverter. It is the best way to ensure your project is efficient, compliant and built to last.

The Future of Smart Inverter Technology

The role of the motor inverter is already vital but its future is where things get really interesting. As we push towards a fully decarbonised grid, these devices are evolving from simple power converters into intelligent energy hubs, acting as the brains behind our entire distributed energy network. The next generation of inverter technology is all about greater efficiency and smarter control, making them indispensable for achieving the UK’s net-zero ambitions.

This evolution is happening on a few key fronts. The integration of artificial intelligence (AI) is turning inverters into predictive energy managers. By analysing usage patterns and grid conditions, an AI-powered inverter can make its own decisions about when to store, release or even trade energy. This optimises performance for rapid EV charging and grid-scale battery storage in real-time.

Materials and Security Advancements

Alongside smarter software, the physical hardware is also getting a major upgrade. The shift towards wide-bandgap semiconductor materials like Silicon Carbide (SiC) represents a massive leap forward. SiC inverters can operate at higher voltages, temperatures and frequencies with far lower energy losses than the old silicon-based units.

What does this actually mean?

- Greater Efficiency: More power gets delivered to the end application, and less is wasted as heat. Simple as that.

- Smaller Footprint: Higher power density allows for much more compact and lightweight inverter designs.

- Improved Reliability: Better thermal performance means the equipment lasts longer and works more dependably.

But as inverters become more connected and intelligent, their security becomes a huge deal. A network of smart inverters is a powerful tool for managing the grid but it also creates a potential target for cyber threats. Because of this, robust cybersecurity protocols are not an optional extra anymore but a fundamental design requirement for any modern inverter.

The next decade will see the inverter cement its position as a cornerstone of the clean energy transition. Its ability to intelligently manage power flow is the key to unlocking the full potential of on-site renewables, grid-scale batteries and widespread transport electrification.

Ultimately, these advancements are not just technical curiosities. They are essential for hitting the UK’s national goals. Achieving net-zero, electrifying our transport system and building a resilient grid all depend on developing smarter, more efficient inverter technology. Understanding this is fundamental to navigating our transition to a cleaner, more sustainable energy future.

Frequently Asked Questions

Getting to grips with the specifics of an inverter for motors can really highlight its value, especially in modern distributed energy projects. Here, we tackle some of the most common questions we hear from clients working on EV charging, battery storage and combined renewables systems across the UK.

What Is the Difference Between an Inverter and a VFD?

This is a frequent point of confusion but the relationship is actually quite straightforward. The simplest way to think about it is that the Variable Frequency Drive (VFD) is the complete control system and the inverter is the most critical component inside it.

A VFD is the whole package that tells the motor what to do. It typically has three main parts: a rectifier (to change AC to DC power), a DC bus (to smooth out that power) and the inverter itself. The inverter is the final, crucial stage that creates the new, adjustable AC waveform needed to precisely control the motor’s speed.

So, while people often use the terms interchangeably, the inverter is technically one (very important) part of the overall VFD.

Can I Use an Inverter with Any Electric Motor?

No, and trying to do so is a recipe for premature motor failure. Standard electric motors are just not built to handle the high-frequency electrical pulses that an inverter produces. This mismatch can cause serious overheating and break down the motor's insulation over time.

For reliable and safe operation, you absolutely must use a specific inverter-duty motor . These are specially constructed with superior insulation, designed from the ground up to withstand the unique electrical stresses from a VFD. Using the right type of motor is not just a recommendation but essential for both performance and longevity, particularly in demanding jobs like rapid EV charging or continuous industrial processes.

It's crucial to match the inverter to an appropriate inverter-duty motor. This pairing ensures the system runs efficiently, avoids damage from voltage spikes, and delivers the expected operational lifespan without unexpected breakdowns.

How Much Energy Can a Motor Inverter Really Save?

The energy savings can be substantial but it all comes down to the application. You will see the biggest wins with equipment that has a variable load, like pumps and fans in industrial settings. In these scenarios, reducing motor speed by just 20% can slash energy consumption by nearly 50% .

For typical applications across the UK in the context of distributed energy, the savings come from optimising energy flow. For example, by enabling charging from on-site renewables or storing cheap off-peak energy in a battery, an inverter minimises reliance on expensive grid power. By precisely matching the system's output to real-time demand, an inverter for motors stops energy from being wasted and can significantly cut operational costs.

At ZPN Energy , we specialise in designing and deploying advanced energy solutions that place intelligent power control right at their core. From battery-backed rapid EV charging to grid-scale energy storage, our systems use proven inverter technology to deliver resilience and efficiency. Discover how we can support your project.