Choosing the Right Inverter for Motor Applications

Think of an inverter as the intelligent go-between for a power source and an electric motor. It's an electronic device that takes direct current (DC) and cleverly converts it into alternating current (AC) at just the right frequency and voltage. The result? Pinpoint control over the motor's speed and torque.

Why Motor Inverters Are Essential for Modern Energy Systems

Imagine trying to control a powerful fire hose with nothing more than a simple on/off tap. That is what running a high-performance electric motor without an inverter is like—all or nothing, with no finesse. An inverter for motor applications provides that crucial layer of control, translating raw electrical power into precise, efficient and adaptable motion. This capability is absolutely fundamental to the UK's ongoing energy transition.

This technology is the lynchpin for a huge range of modern systems. From industrial machinery and mobile EV chargers to grid-scale batteries, inverters are the critical component ensuring that energy is used as effectively as possible. They are especially vital for applications like rapid EV charging, particularly where constrained grid connections make managing power flow a top priority.

The Core Function of an Inverter

At its heart, an inverter’s job is to manage the flow of energy. By converting DC into a finely-tuned AC output, it lets motors operate at variable speeds instead of being stuck at a fixed and often inefficient, full throttle. This unlocks some serious benefits:

- Energy Savings: Motors only draw the power they actually need for the task at hand, which drastically reduces energy waste.

- Enhanced Performance: Precise control over speed and torque leads to smoother operation and much better handling of complex loads.

- Increased Lifespan: By enabling soft starts and controlled acceleration, inverters reduce mechanical stress and extend the life of the equipment.

The ability of inverters to finely regulate power isn't just about efficiency; it's about creating a more flexible and responsive energy infrastructure. This control is central to managing distributed energy resources and ensuring the grid remains stable as more renewables come online.

The growing importance of this technology is clear from market trends. The global inverter duty motor market, valued at around USD 5.4 billion , is expected to shoot past USD 11.6 billion by 2032 . This growth is being driven by industrial automation, infrastructure modernisation here in the UK and regulatory pressure for greater energy efficiency. This really underscores how essential motor control is to achieving national decarbonisation goals and maintaining our energy network's resilience.

To learn more, explore our article on how energy solutions support grid stability and resilience.

How an Inverter Turns Raw Power Into Pinpoint Control

To really get what an inverter does, we have to pop the lid off the "black box" and see how it works its magic. It is a clever, multi-stage process that takes rough electricity and refines it into precisely controlled motion. This is the secret sauce behind everything from mobile EV charging to managing the fluctuating power from on-site renewables.

First things first, the inverter grabs standard AC power from the grid. It immediately rectifies it, flipping it into a stable DC supply. This DC power is then stored in capacitors, which act like a smooth reservoir of energy, ready for the next step. This initial conversion lays the groundwork for all the precise control that comes next.

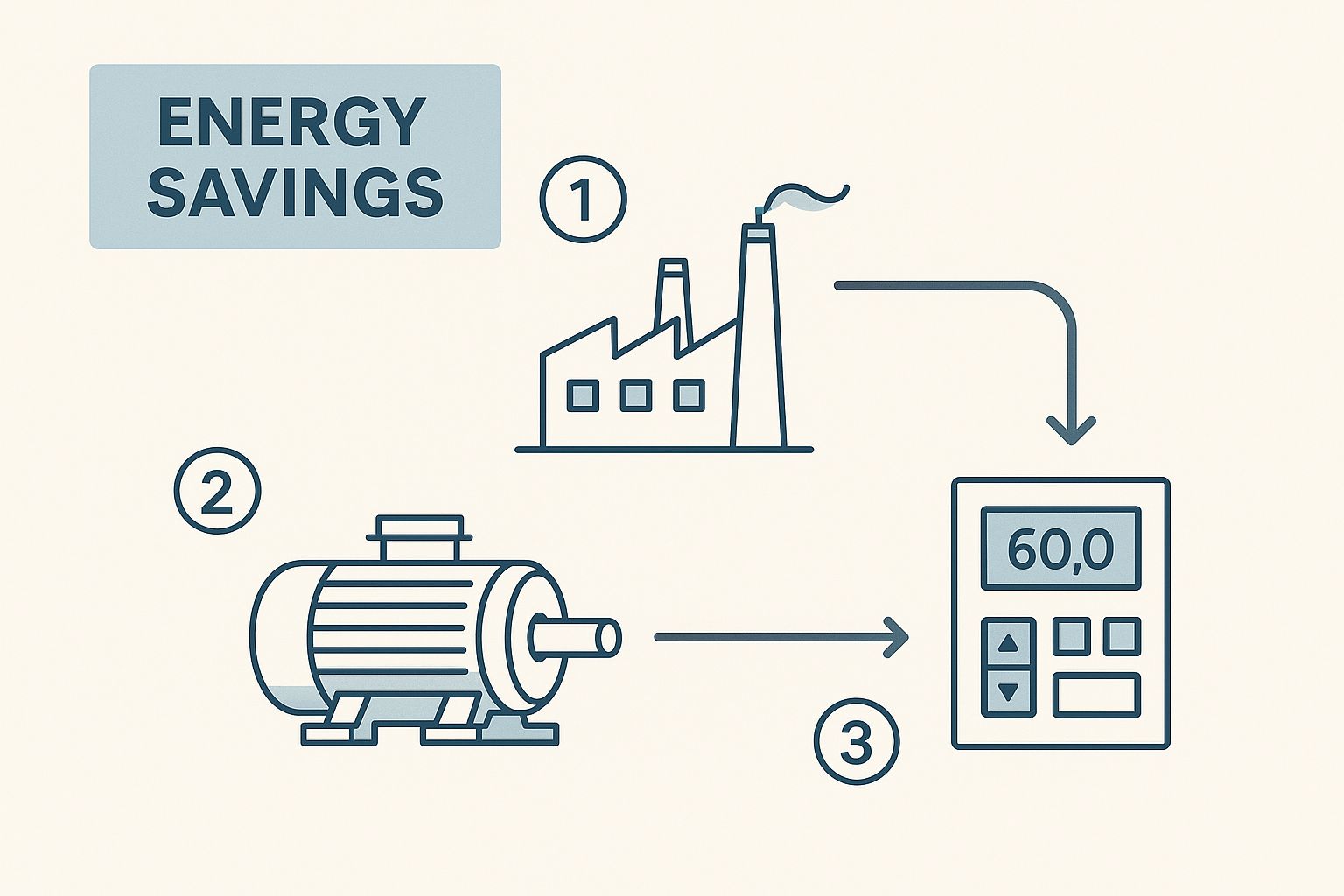

This infographic gives a great visual of how an inverter converts power and racks up some serious energy savings in an industrial setting.

As you can see, by intelligently managing how power flows, inverters help motors run far more efficiently. That translates directly into lower running costs.

Mastering Control with Pulse Width Modulation

The real brains of the operation lie in how the inverter turns this DC power back into AC but this time with a completely custom frequency and voltage. The technique behind this is called Pulse Width Modulation (PWM) .

Imagine the inverter’s switches are like incredibly fast and sophisticated water taps.

Instead of just being on or off, these switches flick open and closed thousands of times every second. By changing how long these "on" pulses last—the "width" of the pulse—the inverter cleverly fakes an AC sine wave. Wider pulses mean more voltage and a faster motor, whilst narrower pulses drop the voltage and slow things down.

This rapid-fire switching is what gives an inverter its incredible precision. By constantly adjusting the width of these electrical pulses, it can feed the motor the exact amount of power it needs at any given moment. The result is smooth acceleration, steady torque and maximum efficiency.

This level of control is what sets modern energy systems apart from the old way of doing things. It is what allows a rapid EV charger to adjust its output to match a car’s battery state or what helps stabilise a weak grid connection by carefully managing power from solar panels and batteries.

The real-world benefits are easy to see:

- Smoother Operation: Gradual starts and stops get rid of the brutal mechanical shock you see with direct-on-line motors.

- Reduced Energy Use: By matching the motor's output to the actual load, no energy gets wasted. This is a game-changer for battery-powered mobile EV charging units where every kilowatt-hour is precious.

- Longer Motor Lifespan: Less mechanical stress on gears, belts and bearings means fewer breakdowns and lower maintenance bills over the equipment's lifetime.

Finding the Right Type of Motor Inverter for Your Needs

Not all inverters are created equal. Choosing the right one is absolutely vital for your application's success, whether that is a simple industrial fan or a high-performance rapid EV charger. Getting your head around the main types is the first step to making a smart decision that balances cost, complexity and performance.

The right inverter for motor control essentially boils down to matching the technology to the job at hand. The most common types fall into three main categories and each works differently. Knowing which is which ensures you get the control you need without paying for features you'll never use.

Voltage Source Inverters (VSI)

Voltage Source Inverters, or VSIs, are the real workhorses of the inverter world. They are the most common type you will come across, especially for general-purpose jobs where reliability and cost-effectiveness are top priorities. A VSI holds a steady DC voltage on the input side and uses a technique called Pulse Width Modulation (PWM) to chop it up, creating a variable AC voltage output for the motor.

Their straightforward design makes them a great fit for:

- Standard industrial motors for pumps and fans.

- Conveyor systems in manufacturing and logistics.

- Less demanding tasks where ultra-precise torque control isn't essential.

For a huge number of projects, a VSI hits that sweet spot between performance and price. But when you get into more advanced systems, like mobile EV charging or managing distributed energy resources, you will often need something more specialised.

Current Source Inverters (CSI)

Unlike a VSI, a Current Source Inverter (CSI) works by maintaining a constant DC current, which it then converts into a variable AC current to drive the motor. This approach makes them exceptionally robust and a solid choice for very high-power applications.

Whilst they are not as common as VSIs, CSIs really shine in specific heavy-duty scenarios. Their big advantage is an innate ability to handle regenerative braking, where the motor acts like a generator and sends power back to the source. This makes them useful for large-scale industrial processes but their higher cost and complexity mean they are usually overkill for smaller jobs.

Vector Control Inverters

When performance is non-negotiable, you turn to Vector Control inverters. They represent the pinnacle of motor control, using complex algorithms to manage the motor’s speed and torque completely independently of each other. Think of it like having separate pedals for how fast the wheels spin and how much pulling power they have.

This precise, independent control of torque is what makes vector control essential for high-performance systems. It allows for smooth, responsive operation even at very low speeds—a critical requirement for rapid EV charging and grid-scale battery systems.

This is the technology you choose when you simply can't compromise. Vector control is the brains behind systems that need to respond instantly and accurately, like managing power from a constrained grid connection or ensuring a seamless supply from on-site renewables and batteries combined.

To make the choice a bit clearer, let's break down how these technologies stack up against each other.

Comparison of Common Motor Inverter Types

| Inverter Type | Operating Principle | Best Suited For | Key Advantage |

|---|---|---|---|

| Voltage Source Inverter (VSI) | Maintains a constant DC voltage and uses PWM to create variable AC voltage. | General-purpose industrial applications like pumps, fans, and conveyors. | Cost-effective, reliable, and straightforward. |

| Current Source Inverter (CSI) | Maintains a constant DC current and converts it to variable AC current. | High-power, heavy-duty industrial processes requiring regeneration. | Extremely robust and has inherent regenerative capabilities. |

| Vector Control Inverter | Uses advanced algorithms to independently control motor speed and torque. | High-performance systems like EV charging, robotics, and grid services. | Unmatched precision, responsiveness, and torque control at all speeds. |

Each type has its place. Your goal is to identify the performance demands of your specific application and choose the inverter that meets them most efficiently.

The Inverter's Role in EV Charging and Grid Stability

The inverter is more than just a piece of industrial kit; it's the unsung hero of the UK’s electric vehicle revolution and a vital component for keeping our national grid stable. Inverters are the silent workhorses managing the flow of power for everything from your home charger to the public rapid charging stations you see at service stations, making sure electricity is delivered both safely and efficiently.

Their job becomes even more critical when you're dealing with a constrained grid connection. Let's face it, in many places, the existing infrastructure just cannot cope with the sudden, massive power demand of multiple EVs plugging in at once. This is where an inverter, often paired with on-site energy storage, steps in to intelligently manage the power draw. It smooths out the peaks and troughs, preventing the local grid from being overwhelmed.

Beyond Charging: Powering a Smarter Grid

But the influence of inverters goes far beyond just getting juice into a car battery. Think of them as the central nervous system for our modern, distributed energy resources, seamlessly knitting together grid-scale batteries and on-site renewables like solar panels. This capability is fundamentally changing how we generate, store and use electricity.

By handling the conversion of DC power from batteries or solar arrays into grid-compliant AC power, inverters are paving the way for a more decentralised and resilient energy network. This is crucial for balancing supply and demand, especially as intermittent renewables start to make up a bigger slice of our energy pie. It's also why understanding the financial sense of integrating EV charging with solar is so important—inverters are right at the heart of this new energy economy.

Bidirectional Inverters and Vehicle-to-Grid Technology

The most advanced inverters are bidirectional , meaning they can direct the flow of power in two directions. This is the technology that unlocks the true potential of Vehicle-to-Grid (V2G) systems, effectively turning every connected EV into a mobile power bank.

With V2G, an EV's battery can be used to send power back to the grid during peak demand times, helping to stabilise the network and reduce the need for fossil fuel power plants. The bidirectional inverter is the gateway that makes this two-way energy exchange possible.

This two-way street for energy is a genuine game-changer for grid stability. A whole network of EVs, all managed by intelligent inverters, can act as one enormous, distributed battery. It can offer services that keep the grid balanced and robust, forming a key part of a smarter, more flexible energy future.

The market growth reflects this shift. In the UK, the photovoltaic (PV) inverter market—which is essential for these renewable systems—generated around USD 412.3 million in 2023. That figure is projected to nearly double to an estimated USD 840.9 million by 2030, a surge driven by the government's strong focus on decarbonisation.

By connecting renewables, batteries and EVs, inverters are the lynchpin technology unlocking an integrated and stable energy supply. To see how these systems come together in the real world, you can learn more about our advanced battery-backed EV charging solutions.

How to Select the Perfect Inverter for Your Motor

Choosing the right inverter is a critical decision that directly shapes the performance, efficiency and lifespan of your application. This is about more than just matching numbers on a spec sheet. It's about truly understanding the unique demands of your system—whether that is a mobile EV charger, a grid-scale battery or an industrial motor running on-site renewables.

Taking a methodical approach helps you sidestep common and costly mistakes, like chronic underperformance or premature equipment failure. The whole process begins with a deep dive into your motor’s specifications and the job it needs to do. Getting this right from the start ensures you invest in a solution that gives you the precise control you need without being over-engineered or dangerously underpowered.

Matching the Inverter to the Motor

Before you even glance at an inverter catalogue, you need to get to know the motor it will be driving. This fundamental first step ensures basic compatibility and safe operation. All the information you need is usually right there on the motor's nameplate.

- Voltage and Power Rating: The inverter’s output voltage has to match the motor’s rated voltage. Just as importantly, the inverter must be sized to handle the motor's full load power rating, which is typically measured in kilowatts ( kW ).

- Full Load Amps (FLA): This figure tells you the maximum current the motor will draw when it is working its hardest. Your inverter needs a continuous current rating equal to or, ideally, greater than the motor's FLA.

- Motor Type: Are you working with a standard induction motor or a high-performance permanent magnet motor? Different technologies have distinct control requirements, which will point you toward the most suitable type of inverter.

Sizing for Application Demands

Once you have the motor’s basic details nailed down, the next step is to look at the specific demands of the application. This is where the subtleties of a system, like a rapid EV charger or a grid-constrained power source, really come into play.

Think about these critical factors:

- Overload Capability: Many jobs, like starting a heavy conveyor belt or firing up a compressor, demand a short, sharp burst of extra torque. The inverter has to be able to supply this temporary overload current without tripping out. You will want to check its overload rating, often given as a percentage for a set time (for example, 150% for 60 seconds ).

- Speed and Torque Control: How much precision do you really need? A simple pump might only require basic speed control. But for a rapid EV charger managing power flow from a battery, you will need the highly precise torque control that only a vector control inverter can offer.

- Environmental Conditions: Where is the inverter going to live? Things like ambient temperature, humidity and exposure to dust will dictate the required IP (Ingress Protection) rating for the enclosure, which is key to ensuring its long-term survival.

Selecting an inverter is always a balancing act between technical requirements and budget realities. Whilst it can be tempting to go for the highest-spec model available, the best choice is always the one that meets all your application's demands reliably and cost-effectively.

The global inverter market is growing at a phenomenal rate, highlighting its essential role in modern energy systems. Forecasts show it expanding from USD 23.56 billion to USD 43.26 billion by 2029 , with UK growth driven by smart grids and the push to integrate renewables with battery storage. You can find more details in a comprehensive inverter market report.

An inverter's role in linking different energy assets is crucial and our guide on integrated energy storage solutions explains this relationship in more detail.

Got Questions About Motor Inverters?

Even when you have a good handle on how an inverter works, putting one into a real-world system always brings up a few practical questions. This final section tackles some of the most common queries we hear, giving you clear, straightforward answers to help you handle the challenges you might face during installation and operation.

The idea is to clear up some of the trickier details you'll encounter, from the initial setup to thinking about long-term performance. Getting these points right is especially important in demanding applications like EV charging hubs and sites with distributed energy systems.

Can I Use Any Inverter with Any Motor?

This is probably the most critical question we get asked and for good reason. The short answer is a definite no .

Getting the pairing right is essential for both safety and performance. You absolutely must match the inverter to the motor's core specs—its voltage, power rating (kW) and its full-load current (amps).

Beyond the raw numbers, the type of motor you're using is just as important. A standard AC induction motor has completely different control needs compared to a high-performance permanent magnet motor. Using the wrong inverter is a recipe for disaster. At best, you will get poor performance and wasted energy. At worst, you could permanently damage the motor, the inverter or both. Always, always check the manufacturer’s documentation for both parts to confirm they are a good match.

What Is Electrical Noise and Why Does It Matter?

Electrical noise, often called electromagnetic interference (EMI), is an unavoidable side effect of the rapid, high-frequency power switching that happens inside an inverter. The easiest way to think of it is as electrical 'static' that can mess with other sensitive electronic equipment operating nearby.

In environments like rapid EV charging hubs or industrial sites with on-site renewables, managing EMI isn't just a recommendation—it's vital for keeping the entire system running reliably. Uncontrolled noise can disrupt communication signals, throw off control systems and even interfere with grid-scale battery management.

Dealing with EMI usually involves a few key steps:

- Shielded Cabling: Using properly earthed, shielded cables for the link between the inverter and the motor is the first line of defence. It helps contain the noise right at the source.

- Correct Installation: This might sound obvious but simply following the manufacturer's guidelines for grounding and component spacing makes a huge difference.

- Filtering: For more sensitive applications, installing dedicated line filters can suppress the noise before it has a chance to spread through the rest of your electrical system.

How Far Can the Inverter Be from the Motor?

The physical distance between the inverter and the motor is another practical point that's often overlooked. As that cable run gets longer, you start running into problems like voltage drop and something called capacitive coupling. Both can degrade the motor's performance and impact the inverter's reliability over time.

There is no single ‘maximum distance’ that fits every situation but a solid rule of thumb is to keep the cable as short as you practically can.

If you have to cover a longer distance, you will need to compensate. This might mean using thicker gauge cables to minimise the voltage drop or installing output reactors or filters to clean up the electrical signal. This is a crucial design consideration, especially in compact setups like mobile EV charging units where every centimetre of space is planned.

At ZPN Energy , we specialise in advanced energy solutions that place intelligent power control right at their core. From rapid EV charging infrastructure to integrated battery storage systems, our technology is designed to deliver efficiency, reliability, and performance.

Discover how our pioneering energy management systems can support your project by visiting us at https://www.zpnenergy.com.