Unlocking Power with Electric Motor Inverters

Think of an electric motor inverter as a kind of universal translator for electricity. It's the unsung hero working behind the scenes in everything from your electric car to the massive battery storage systems that stabilise our power grid. This guide breaks down how these crucial devices convert stored DC battery power into the usable AC power that our modern world runs on.

The Unseen Heart of Modern Electrification

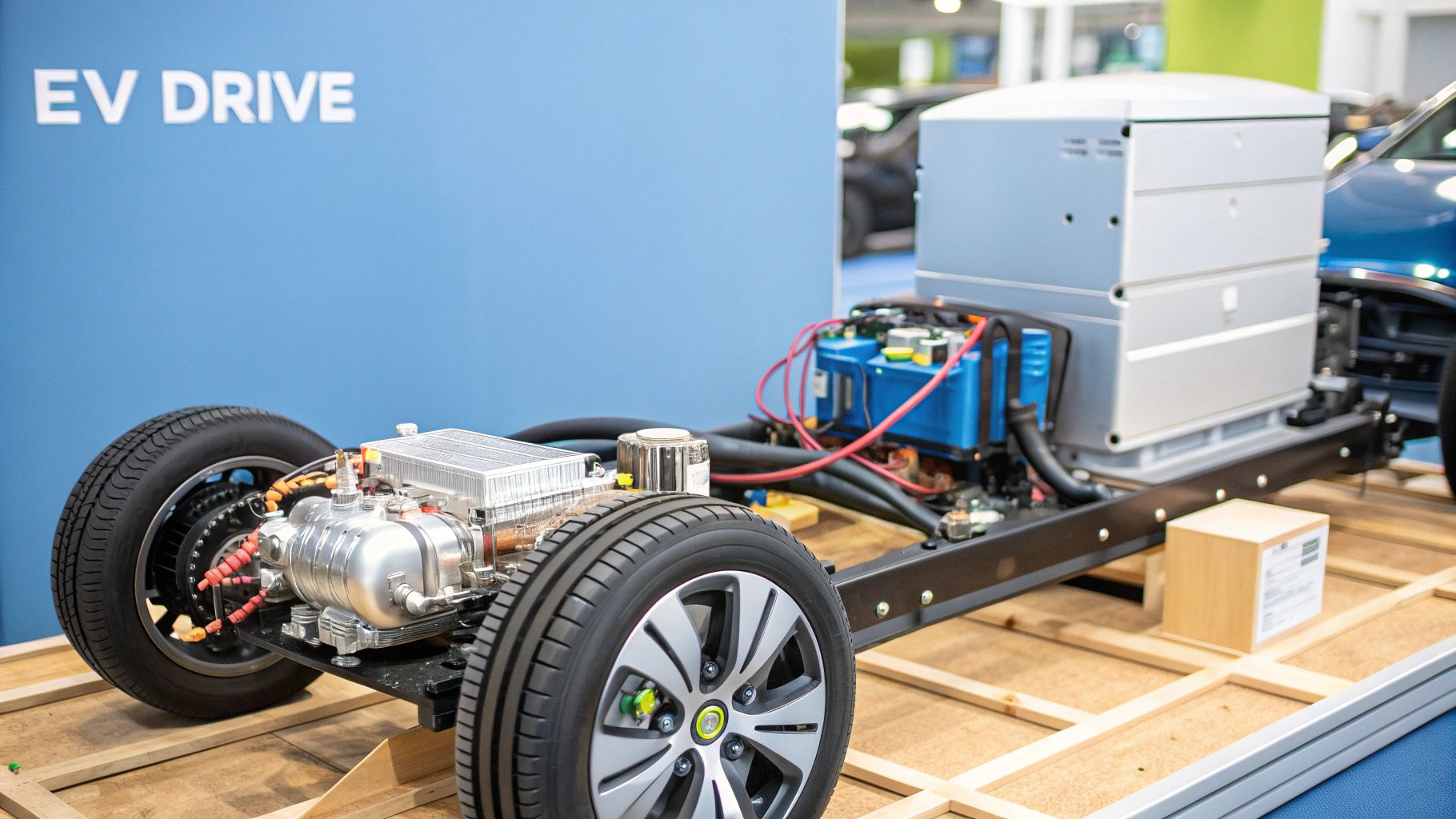

At its heart an electric motor inverter is a power electronics device that takes Direct Current (DC) from a source like a battery and turns it into Alternating Current (AC) to run an electric motor. Imagine the battery in an electric vehicle (EV) as a big tank of DC power. The motor that spins the wheels however needs a very specific, finely controlled AC supply. The inverter is the intelligent go-between managing this vital energy conversion seamlessly.

But its job is much bigger than just simple conversion. In the context of the UK’s booming green energy sector inverters are the critical link connecting several key technologies. They are absolutely essential for managing the complex dance between EV charging, grid-scale batteries and on-site renewables like solar. This makes them central to solving some of our biggest energy headaches especially when dealing with weak or constrained grid connections.

Why Inverters Are Critical for Our Energy Future

The demand for this kind of sophisticated power electronics is soaring and a big reason is the rapid shift to electric vehicles and the infrastructure needed to support them. Inverters are not just found inside the cars themselves; they are also the core component of the rapid charging stations that get them back on the road.

The European power inverter market which includes the UK is part of a massive global expansion. The market was valued at around USD 7.38 billion in 2024 and is expected to grow at a blistering 18.6% CAGR between 2025 and 2030 . As one of Europe's leading EV adopters the UK has seen inverter demand shoot up driven by government incentives, tighter emissions rules and huge consumer appetite for both battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs). For a deeper dive you can explore the full EV power inverter market report.

An advanced inverter doesn't just push power in one direction; it intelligently manages energy flow, deciding when to charge a battery, when to power a motor and even when to send electricity back to the grid. This bidirectional capability is what makes modern distributed energy systems truly dynamic.

Unpacking the Inverter's Core Functions

To really get a feel for their importance it helps to see how inverters operate in different scenarios. They are incredibly versatile devices adapting their role to fit the system's needs whether that's in a mobile EV charger or a large-scale distributed energy project.

Before we dive deeper it’s useful to see their primary functions at a glance. The table below summarises the key roles inverters play across the modern energy landscape giving a quick overview of what we'll be covering.

Key Functions of Electric Motor Inverters in Modern Energy Systems

| Application Area | Primary Inverter Function | Impact on System Performance |

|---|---|---|

| Rapid EV Charging | Converts AC grid power to DC for the battery (in the charger) and DC battery power to AC for the vehicle's motor. | Enables fast, efficient charging and delivers smooth, responsive driving control. |

| Grid-Scale Batteries (BESS) | Manages bidirectional energy flow, charging from the grid or renewables and discharging AC power back to the grid when needed. | Stabilises the grid, enables peak shaving and supports the integration of intermittent renewable sources like solar. |

| On-Site Renewables | Converts DC power generated from solar panels into usable AC power for a building or for export to the grid. | Allows homes and businesses to generate and use their own clean energy, reducing reliance on the grid. |

| Constrained Grid Connections | Facilitates charging of a local battery from a weak grid connection, then delivers high-power AC/DC for rapid EV charging. | Makes rapid charging viable in locations where grid upgrades are impossible or too expensive. |

As you can see the inverter is far more than a simple converter. It’s a smart gatekeeper for energy ensuring power gets to the right place, in the right format, at exactly the right time.

How Inverters Translate DC Power into AC Motion

At its heart an electric motor inverter does something that sounds simple but is absolutely essential: it converts Direct Current ( DC ) from a battery into Alternating Current ( AC ) to run a motor. Think of it as a highly skilled translator fluent in two very different electrical languages.

A battery is like a reservoir storing energy and releasing a steady one-way flow of DC power. An electric motor on the other hand needs a constantly changing, oscillating AC supply to create the rotating magnetic fields that produce motion.

But this conversion is not just a simple flip of a switch. Modern inverters are masters of electrical control shaping the power they send out with incredible precision. They do not just create any old AC wave; they craft a perfect, tailor-made one. This is what gives an electric vehicle its seamless and instant torque and it is what separates a basic power converter from the sophisticated brain of an EV's drivetrain.

The Power of Pulse Width Modulation

So what is the secret to this pinpoint control? It’s a technique called Pulse Width Modulation (PWM) .

Imagine you have a light dimmer but instead of turning a dial you are flicking the switch on and off thousands of times a second—far too fast for your eyes to see. By changing how long the switch stays on versus off in each tiny time frame (adjusting the "pulse width") you can control the average brightness of the bulb. A longer "on" time means a brighter light and a shorter one means it is dimmer.

Electric motor inverters do something very similar with electricity. Inside high-speed switches—usually advanced semiconductors—chop up the smooth DC input from the battery into a series of precisely timed pulses. By varying the width and frequency of these pulses the inverter can build a simulated AC sine wave of almost any voltage or frequency it needs. This is how it tells the motor to spin slowly, accelerate like a rocket or even run in reverse for regenerative braking.

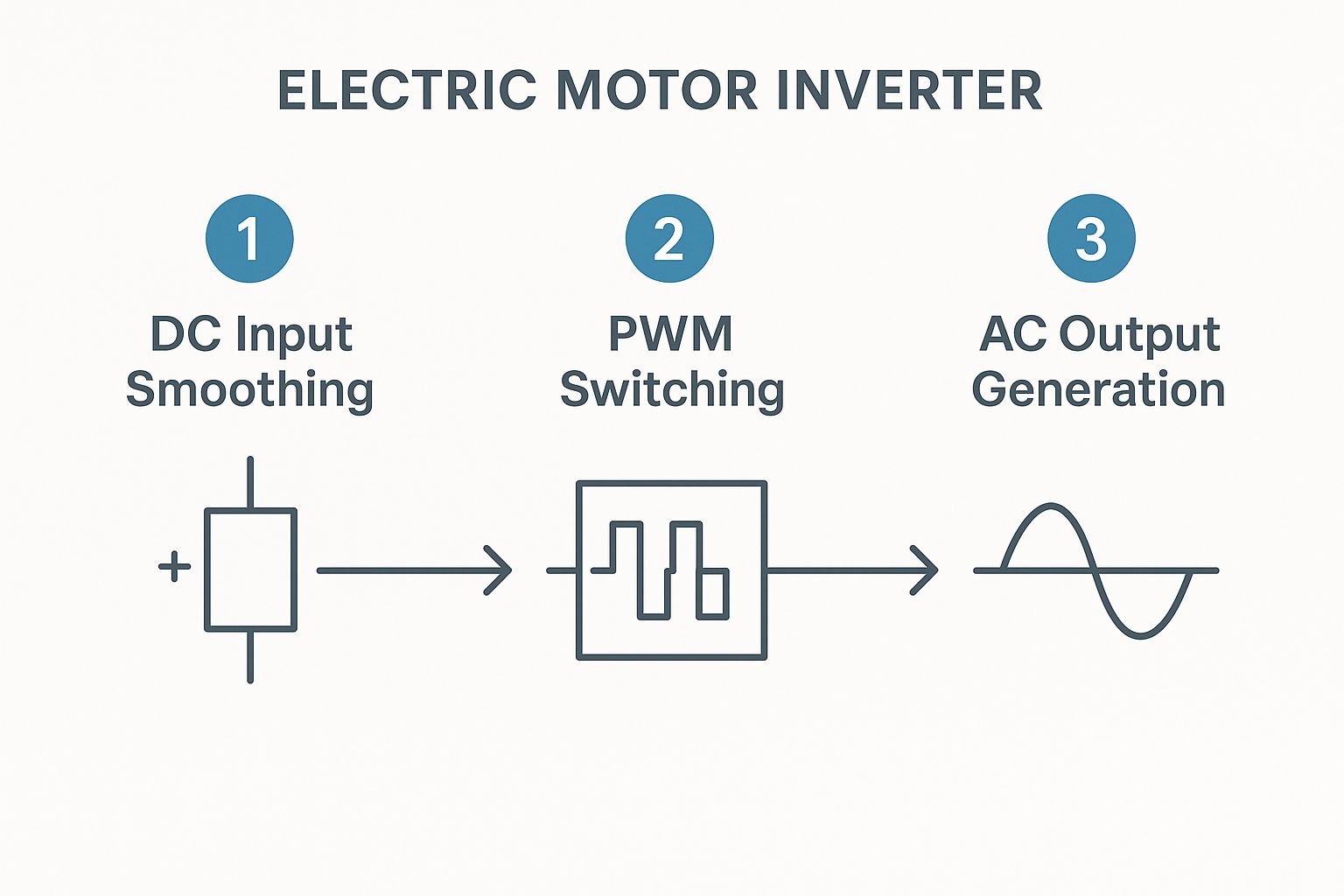

The infographic below breaks down the three core steps of this process from smoothing out the initial DC input to generating the final AC output that drives the motor.

This gives you a clear picture of how raw DC power is first refined and then meticulously modulated by the inverter's switches to create the powerful AC waveform the motor needs.

From Pulses to Precise Motion

This ability to finely tune the AC output is what makes inverters so crucial not just in EVs but in advanced applications like rapid charging stations and grid-scale battery systems. The inverter is in constant communication with the vehicle's control systems adjusting the frequency and voltage it sends to the motor in real-time, all based on what the driver is doing.

This immediate response brings several huge benefits:

- Instant Torque: The inverter can slam maximum current to the motor right from a standstill, delivering that powerful, press-you-into-your-seat acceleration EVs are famous for.

- Variable Speed Control: By simply changing the frequency of the AC output the inverter can make the motor spin at any speed with incredible accuracy.

- High Efficiency: Modern inverters are exceptionally good at their job, wasting very little energy as heat during the conversion. This helps maximise the vehicle's range or the output of a battery storage system.

- Regenerative Braking: When an EV slows down the inverter flips its role. It takes the AC generated by the slowing motor (which is now acting like a generator), converts it back into DC and sends it back to recharge the battery. It’s a brilliant way of capturing energy that would otherwise be lost as heat.

The sophistication of an inverter’s PWM control directly translates to real-world performance. A higher switching frequency and more precise pulse control create a smoother AC waveform. The result? A quieter, more efficient motor and a far more responsive driving feel.

To really appreciate how inverters achieve this level of control it helps to understand the types of motors they are often paired with. High-performance Permanent Magnet Synchronous Motors , common in modern EVs, are a great example. This perfect partnership between inverter and motor is the key to unlocking the full potential of electrification from the car on your drive to the batteries keeping our national grid stable.

Powering the EV Revolution and Rapid Charging

If an EV’s battery is its fuel tank then the traction inverter is the mastermind controlling the engine. This single component dictates everything that matters to the driver: acceleration, efficiency and how far you can go on one charge. When you press the accelerator it’s the inverter that translates that simple foot movement into a perfectly controlled surge of AC power delivering that signature instant torque.

But its job does not stop when you lift your foot off the pedal. During braking the inverter flips its role on its head. It captures the car's momentum—energy that’s just wasted as heat in a petrol or diesel car—and uses it for regenerative braking . By converting this kinetic energy back into DC power it sends a little top-up to the battery adding precious miles to your range.

This technology is at the heart of the EV boom. The global EV traction inverter market is set to be worth around USD 7.8 billion in 2025 but it’s expected to more than double to a staggering USD 15.5 billion by 2030. That kind of growth shows just how crucial the inverter is to making EVs better, more efficient and more practical for everyone.

The Inverter's Role in Rapid EV Charging

The inverter’s influence does not just stay within the car; it’s a game-changer for the charging infrastructure that supports it. For rapid EV charging especially in places where the grid is weak inverters are the secret weapon. They are the core of systems that blend on-site renewables and grid-scale batteries to deliver power where it’s needed most.

Imagine a charging station with a limited grid connection. An inverter-managed battery system can quietly ‘trickle charge’ itself during off-peak hours when electricity is cheap and plentiful. When an EV pulls up needing a fast charge the inverter unleashes a high-power DC surge straight from the battery providing a rapid top-up that the grid simply couldn’t handle on its own.

This setup completely decouples charging speed from the grid's limitations. A smart inverter, working with a battery, can deliver 150kW of rapid charging power from a grid connection that can only supply 30kW . Suddenly fast charging becomes possible almost anywhere.

Bidirectional Charging and Distributed Energy

The next big step for inverters is bidirectional charging often called Vehicle-to-Grid (V2G). With advanced bidirectional inverters an EV can not only pull power from the grid but also push it back. This transforms the car from a simple mode of transport into a mobile battery on wheels.

The implications for our wider energy network are massive:

- Grid Stabilisation: During peak demand a whole fleet of connected EVs could send a small amount of power back to the grid, helping to balance supply and prevent blackouts.

- Renewable Energy Integration: EVs can soak up excess solar or wind power during the day and release it in the evening, smoothing out the peaks and troughs of renewable generation.

- Financial Incentives: Drivers could actually get paid for the energy they share creating a brand-new revenue stream just for owning an EV.

This kind of smart energy management turns every electric vehicle into a small part of a more resilient, flexible distributed energy system. You can already see the benefits of this advanced inverter tech in models like the Chery Eq1 EV. By bringing together mobile EV charging, grid-scale batteries and intelligent inverters we can build a stronger energy ecosystem for everyone. It’s technology like this that makes it possible to unleash ultra-rapid DC charging even in the most challenging locations.

Managing Grid-Scale Batteries and On-Site Renewables

It is not just about electric vehicles. Electric motor inverters are the command centre for two other cornerstones of modern energy: Battery Energy Storage Systems (BESS) and sites that generate their own power from renewables like solar. In these sophisticated set-ups the inverter acts as an intelligent energy traffic controller.

It masterfully directs the flow of electricity between multiple sources and destinations. Think of it converting DC power from solar panels, managing the charge and discharge of a DC battery and delivering perfectly synchronised AC power to a local facility or even back to the wider grid.

The Inverter as an Intelligent Energy Hub

An inverter in a BESS or a combined renewables site is far more than a simple converter; it is the brain of the entire operation. It makes real-time decisions based on energy generation, storage levels, site demand and grid conditions ensuring everything runs at peak performance and cost-effectiveness.

This intelligent management is fuelling a major expansion in the UK's power electronics market. Driven by the wider trends in renewable energy and electrification the UK inverter market is projected to grow at a rate of about 15.2% CAGR through 2025, rising again to 15.8% CAGR by 2029. As the UK deploys more smart grid systems and integrates renewable sources the demand for these crucial components just keeps climbing.

Peak Shaving for Maximum Cost Savings

One of the smartest strategies an inverter can orchestrate is peak shaving . This involves using a BESS to strategically manage electricity costs which is a game-changer for commercial and industrial sites with high energy consumption.

The logic is simple but incredibly powerful:

- Charge during off-peak hours: The inverter charges the battery when electricity from the grid is cheap, usually overnight.

- Discharge during peak hours: When grid prices spike during periods of high demand the inverter discharges the battery, supplying the site with that stored, low-cost energy instead of expensive grid power.

This simple act of storing cheap energy and using it later all managed by the inverter can lead to massive reductions in electricity bills. It boosts energy independence and gives businesses real control over one of their largest operational costs.

By intelligently managing energy flow, a BESS with an advanced inverter can reduce a commercial site's reliance on the grid during the most expensive periods by over 70% , turning a variable cost into a predictable asset.

Grid-Forming Inverters for Unbreakable Resilience

Perhaps the most impressive capability of modern inverters is found in grid-forming technology. A standard 'grid-following' inverter needs a stable signal from the national grid to work; if the grid goes down so does the inverter.

A grid-forming inverter however is in a different league. During a power cut it can generate its own stable AC frequency and voltage effectively creating an independent, self-sufficient microgrid. This provides an invaluable layer of resilience for businesses where uninterrupted power is non-negotiable.

This ability transforms a BESS from a simple storage unit into a complete backup power solution. The inverter seamlessly switches from grid-connected mode to island mode ensuring that critical operations continue without a flicker. This capability is vital for facilities like data centres, manufacturing plants and hospitals. By understanding the full potential of inverters in modern energy storage solutions , businesses can build systems that are not only efficient but also exceptionally robust.

Solving Grid Constraints for EV Charging

One of the biggest roadblocks to rolling out widespread rapid EV charging isn’t the technology or the demand—it’s the local grid. Many of the best spots for charging hubs like motorway service stations or city-centre car parks just don’t have the electrical muscle for high-power chargers. Getting the grid connection upgraded is notoriously expensive and can drag on for years creating a massive bottleneck.

This is where a clever combination of electric motor inverters and Battery Energy Storage Systems (BESS) comes in. It’s an elegant and incredibly effective solution. The strategy is simple but powerful: the system slowly ‘trickle charges’ a large on-site battery from a weak grid connection, often overnight or during off-peak hours when electricity is cheapest.

Then when a driver pulls up needing a fast charge the inverter steps in. It acts as the gatekeeper unleashing a huge surge of DC power straight from the battery to the car completely sidestepping the grid’s limitations. This means a site can offer rapid charging services that would be impossible with its direct grid connection alone.

Making Rapid Charging Possible Anywhere

This inverter-BESS approach completely changes the game for where rapid charging is feasible. It disconnects the power delivered to the EV from the grid's real-time capacity opening up a world of new locations for charging infrastructure. The inverter is not just a simple power converter; it’s an intelligent energy manager actively directing power flows to overcome real-world infrastructure weaknesses.

This technology is proving vital for several key applications:

- Mobile EV Charging: Think of temporary events, fleet depots needing extra capacity or emergency roadside assistance. Inverter-powered mobile charging units can be deployed with a fully charged battery ready to deliver a rapid charge without needing any grid connection at all.

- Remote Charging Hubs: Service stations and rural destinations can install rapid chargers without the long wait and high cost of grid upgrades. The BESS and inverter combo acts as a powerful energy buffer on-site.

- Fleet Depot Charging: Logistics firms can top up their electric fleets overnight using a modest grid connection to fill a BESS. During the day the inverter ensures vehicles get a quick boost between shifts without putting a strain on the local supply.

By using an inverter to manage on-site storage a location can offer 150kW rapid charging from a grid connection that can only supply 50kW . This is a game-changer for speeding up the expansion of the UK's charging network.

This smart use of inverters and batteries transforms a grid limitation from a dead end into a manageable logistical challenge. It shifts the focus from waiting on huge, slow infrastructure projects to deploying smart, localised energy systems right now.

Integrating Renewables for True Sustainability

The benefits do not stop at just solving grid problems. When you add on-site renewables like solar panels into the mix the inverter becomes the heart of a self-sufficient microgrid. It can prioritise charging the battery with clean, free solar energy during the day.

This stored solar power can then be used for EV charging later on even after the sun goes down further cutting reliance on the grid and bringing down running costs. The inverter seamlessly juggles the complex dance between solar generation, battery storage, grid power and EV charging demand.

This creates a charging ecosystem that is resilient, cost-effective and genuinely sustainable. Understanding how these components work together is key to appreciating how ZPN’s energy solutions support grid stability and resilience. By orchestrating these distributed energy resources the inverter not only helps accelerate EV adoption but also strengthens the local energy network making it more robust and flexible for whatever comes next.

Choosing the Right Inverter for Your Project

Picking the right electric motor inverter isn't just a technical detail; it's a decision that shapes the performance, efficiency and long-term success of your entire EV charging or BESS project. Think of it like choosing the right engine for a high-performance car—a mismatch will leave you with sluggish performance and a constant stream of reliability issues.

Your first port of call is always the power rating . It’s vital to look past the headline number and understand the difference between continuous and peak power. Continuous power is what the inverter can deliver day in, day out while peak power is a short-term burst for demanding moments like a motor start-up. For something like a rapid EV charging hub a high continuous power rating is non-negotiable for delivering sustained, high-speed charging.

Matching Specifications to Application Needs

Beyond raw power voltage compatibility is absolutely critical. We are seeing a clear shift towards 800V EV architectures moving away from the more traditional 400V systems. This jump to 800V allows for much faster charging and reduces energy loss but it demands an inverter specifically designed to handle these higher voltages. You can’t just plug and play.

Another crucial fork in the road is the cooling method . Air-cooled inverters are often simpler and more cost-effective making them a good fit for smaller systems. But when you’re dealing with high-power applications like grid-scale batteries or busy rapid charging stations liquid-cooled inverters are in a class of their own. They manage heat far more effectively which allows for greater power density and keeps everything running smoothly under constant, heavy loads.

A tiny difference in an inverter's efficiency rating can have a massive financial impact down the line. A jump from 95% to 98% efficiency might not sound like much but for a large-scale BESS that 3% reduction in wasted energy translates directly into huge operational cost savings over the system's lifetime.

The Impact of Advanced Semiconductor Materials

The materials inside the inverter are just as important as the numbers on its spec sheet. The move away from traditional silicon (Si) semiconductors to advanced materials like Silicon Carbide (SiC) is a genuine game-changer for power electronics.

SiC inverters bring several massive advantages to the table. They can operate at higher voltages, frequencies and temperatures all of which leads to greater efficiency and a much higher power density. In simple terms a SiC inverter can be smaller, lighter and more efficient than a silicon-based unit with the same power rating. This makes them perfect for applications where space is tight like mobile EV charging units.

To make this clearer let's break down the key differences between these two technologies.

Inverter Technology Comparison SiC vs Traditional Silicon

The table below gives a straightforward comparison of how newer Silicon Carbide (SiC) inverters stack up against their traditional Silicon (Si) predecessors.

| Feature | Traditional Silicon (Si) Inverter | Silicon Carbide (SiC) Inverter |

|---|---|---|

| Efficiency | Good, typically around 95-97%. | Excellent, often exceeding 98%. |

| Power Density | Lower, resulting in larger and heavier units. | Higher, allowing for smaller, lighter designs. |

| Heat Generation | Generates more waste heat, requiring larger cooling systems. | Produces less heat, enabling more compact cooling solutions. |

| Switching Speed | Slower switching speeds. | Faster switching, leading to improved performance. |

| Cost | Generally lower upfront cost. | Higher initial cost but offers greater long-term savings. |

While SiC technology comes with a higher initial price tag the long-term benefits in efficiency, size and cooling requirements often provide a much better return on investment.

Ultimately choosing the right inverter is about balancing these technical specifications against the real-world operational and commercial goals of your project.

Your Questions Answered: Electric Motor Inverters

What is the Difference Between an Inverter and a Converter?

It’s a great question and the simple answer is they do opposite jobs but work as a team. Think of an inverter as the component that turns DC power from a battery into the AC power an electric motor needs to spin.

A converter does the reverse. A classic example is the onboard charger in an EV which takes AC power from the grid and converts it into DC to fill up the battery. In more advanced kit like bidirectional chargers or our BESS units a single, sophisticated device handles both jobs seamlessly.

How Much Does an Inverter Affect My EV's Range?

Quite a bit actually. The inverter's efficiency is a major factor in how far your EV can travel on a single charge. A better, more efficient inverter loses less energy as heat when it changes DC power to AC which means more of that precious battery power actually gets to the wheels.

For instance boosting efficiency from 95% to 98% might not sound like a huge leap but it can easily add several miles of driving range from the exact same battery. You’re simply wasting less energy getting the power to the road.

This efficiency really comes into its own during regenerative braking. A high-quality inverter is better at capturing the kinetic energy when you slow down, converting it back into usable DC power to top up the battery and stretch your journey that little bit further.

What Does a Grid-Forming Inverter Do?

This is where things get really clever. A standard inverter is a ‘grid-following’ device. It needs to see a stable signal from the National Grid to work and for safety it will shut down instantly if there’s a power cut. A ‘grid-forming’ inverter is a different beast altogether.

It has the remarkable ability to generate its own stable AC power signal completely independent of the grid. This allows it to create and manage its own self-sufficient microgrid powered by a BESS. It is the key technology for providing continuous backup power during an outage or for running an entire site completely off-grid, guaranteeing true energy resilience.

At ZPN Energy we design and deploy advanced energy solutions built around high-performance electric motor inverters. From rapid EV charging to grid-scale battery storage, our systems provide the intelligent power management you need. Discover our integrated energy solutions at https://www.zpnenergy.com.